Electric power construction maintenance tool

A technology for electric power construction and appliances, which is applied in the direction of hoisting devices, lifting frames, etc., can solve the problems of inability to lift and lower heavy objects and high-altitude operations, resources are not fully utilized, and equipment labor costs are high, so as to reduce equipment and labor costs and quickly The effect of convenient fixed clamping and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

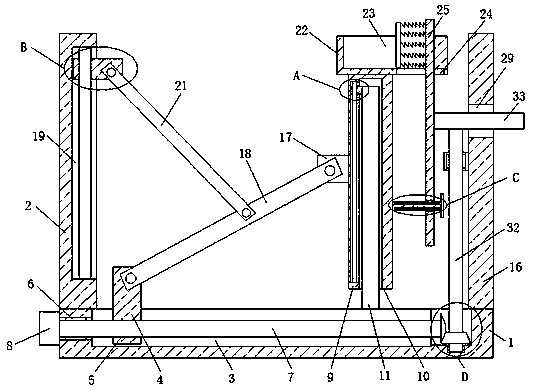

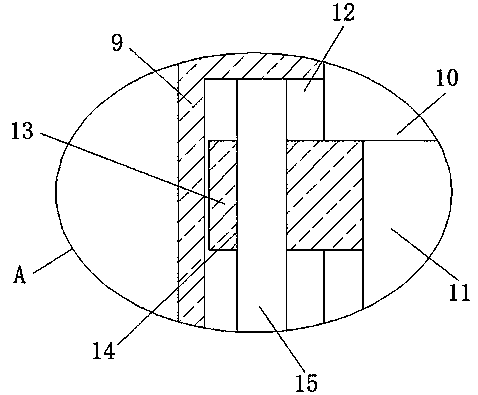

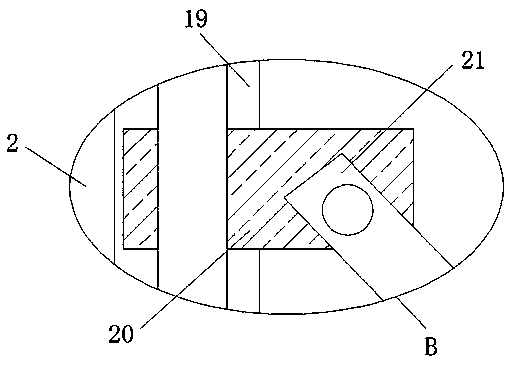

[0027] refer to Figure 1-6 , a kind of electric power construction overhaul appliance, comprises fixed base 1, and the top of fixed base 1 is fixedly installed with first rod 2 and second rod 16, and the top of fixed base 1 is provided with first chute 3, and inside first chute 3 The first slider 4 is slidably installed, and the first slider 4 is provided with a threaded hole 5, and one side of the fixed base 1 is provided with a first rotation hole 6, and the first chute 3 and the first rotation hole 6 are installed in rotation. There is the same threaded rod 7, one end of the threaded rod 7 passes through the threaded hole 5 and is threadedly connected with the threaded hole 5, a servo motor 8 is fixedly installed on one side of the fixing seat 1, and one end of the threaded rod 7 extends through the first rotation hole 6 To the outside of the fixed seat 1 and fixedly connected with the output shaft of the servo motor 8, a sliding plate 9 is arranged above the fixed seat 1,...

Embodiment 2

[0036] refer to Figure 1-6 , a kind of electric power construction overhaul appliance, comprises fixed base 1, and the top of fixed base 1 is fixedly connected with first rod 2 and second rod 16 by bolt, and the top of fixed base 1 is provided with first chute 3, and the first chute 3 is slidably installed with a first slider 4, the first slider 4 is provided with a threaded hole 5, one side of the fixed seat 1 is provided with a first rotation hole 6, and the first slide groove 3 and the first rotation hole 6 The same threaded rod 7 is installed in rotation, and one end of the threaded rod 7 runs through the threaded hole 5 and is threadedly connected with the threaded hole 5. One side of the fixing seat 1 is fixedly connected with a servo motor 8 by bolts, and one end of the threaded rod 7 runs through the first The rotation hole 6 extends to the outside of the fixed seat 1 and is fixedly connected with the output shaft of the servo motor 8. A sliding plate 9 is arranged ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com