Shield tunneling machine split starting tunneling pipeline extending and supporting device and shield tunneling machine split starting method

A split-starting and shield machine technology, which is applied to mining equipment, pipeline supports, mechanical equipment, etc., can solve problems such as crushing, tunneling pipelines being soaked in water, and dragging and grinding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

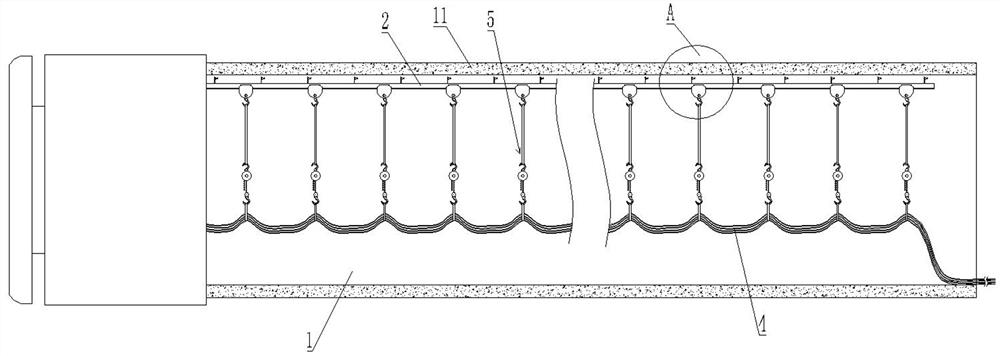

[0034] A shield machine split start excavation pipeline extension supporting device, its structure please refer to Figure 1 to Figure 7 .

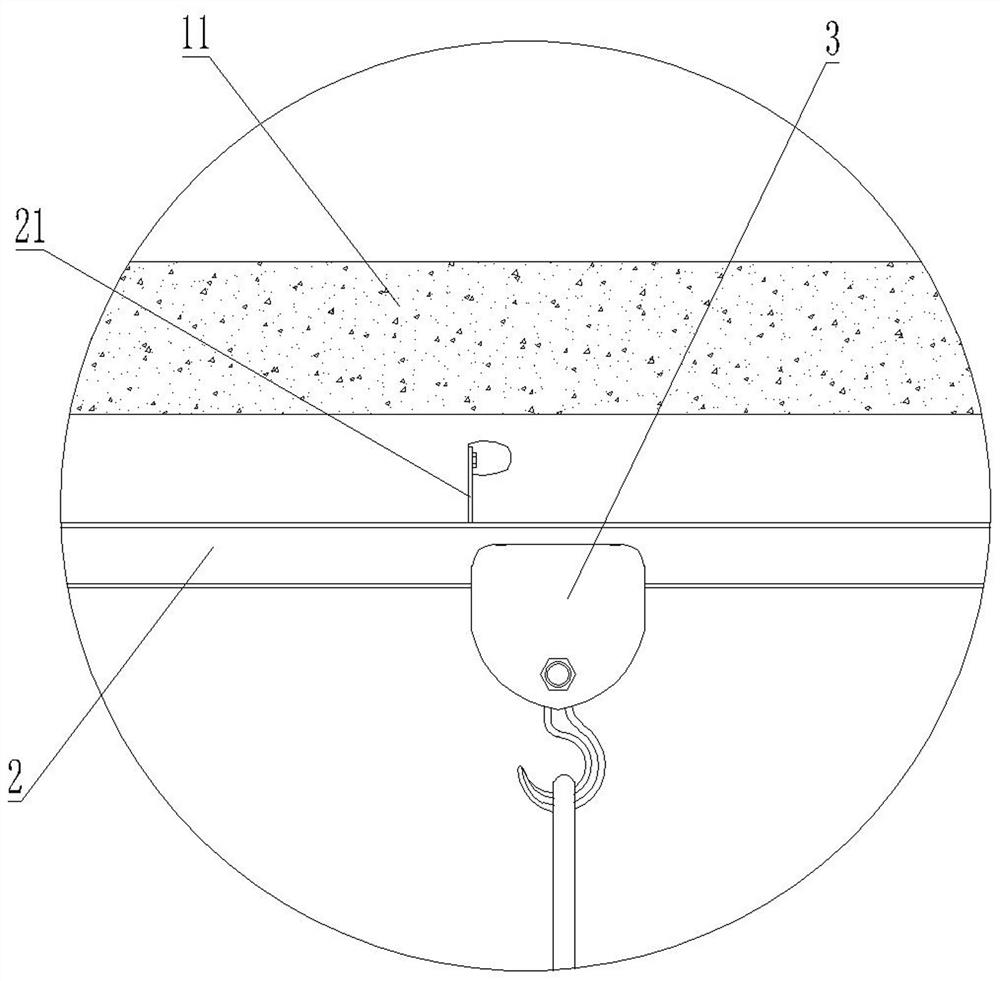

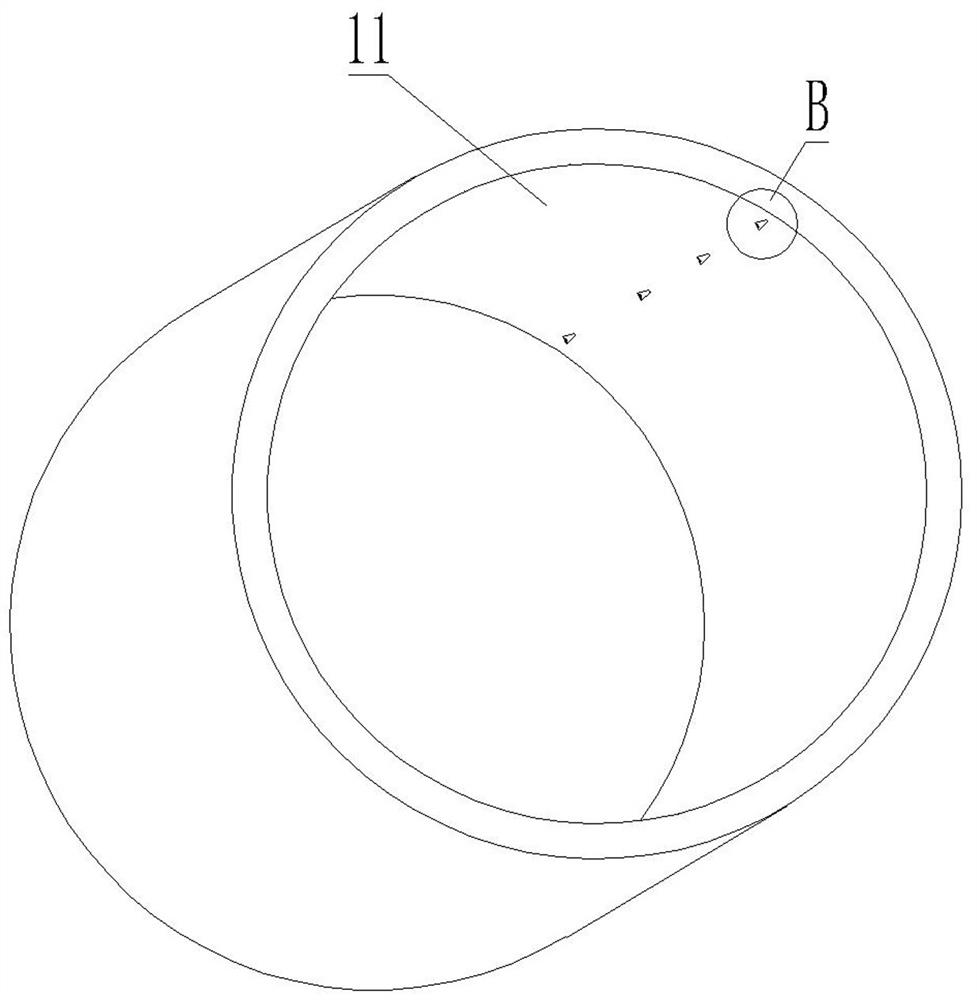

[0035] Such as figure 1 with figure 2 As shown in the figure, the shield machine’s split start excavation pipeline extension support device includes a track 2 installed on the segment lining 11 of the start tunnel 1. The track 2 is made of I-beams connected end to end, and the intervals on the track 2 are fixed. A plurality of hanging boards 21 are provided, the lower ends of the hanging boards 21 are welded on the track 2 , and the tops of the hanging boards 21 are fixed on the segment lining 11 . combine image 3 with Figure 4 As shown, the segment lining 11 is provided with a bolt hand hole 111, and a screw sleeve 112 for connecting the hanging plate is pre-embedded on the side of the bolt hand hole 111. The segment lining 11 is assembled from prefabricated segments. The screw sleeve 112 is pre-embedded in the piece, and the scr...

Embodiment 2

[0039] A separate starting method of the shield machine, please refer to Figure 8 to Figure 10 .

[0040] In this shield machine split start method, the shield machine split start excavation pipeline extension supporting device in Embodiment 1 is used. The split initiation method of the shield machine comprises the following steps:

[0041] (1) Lower the main engine of the shield machine into the starting working well, and after the main engine is placed in the starting working well, start excavation at the working face in the starting working well.

[0042] In this step, the starting working shaft is a vertical shaft constructed at the selected construction starting position on the tunnel construction route. Due to the limitation of construction cost and construction area, it is unrealistic to construct a starting working shaft that can accommodate the entire shield machine However, it is more reasonable to build a starting working shaft that can accommodate the main engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com