Washing device detergent manual feeding control method

A technology of washing equipment and control method, which is applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of waste of detergent and difficult to clean, so as to ensure the washing effect, avoid poor user experience, and improve user experience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

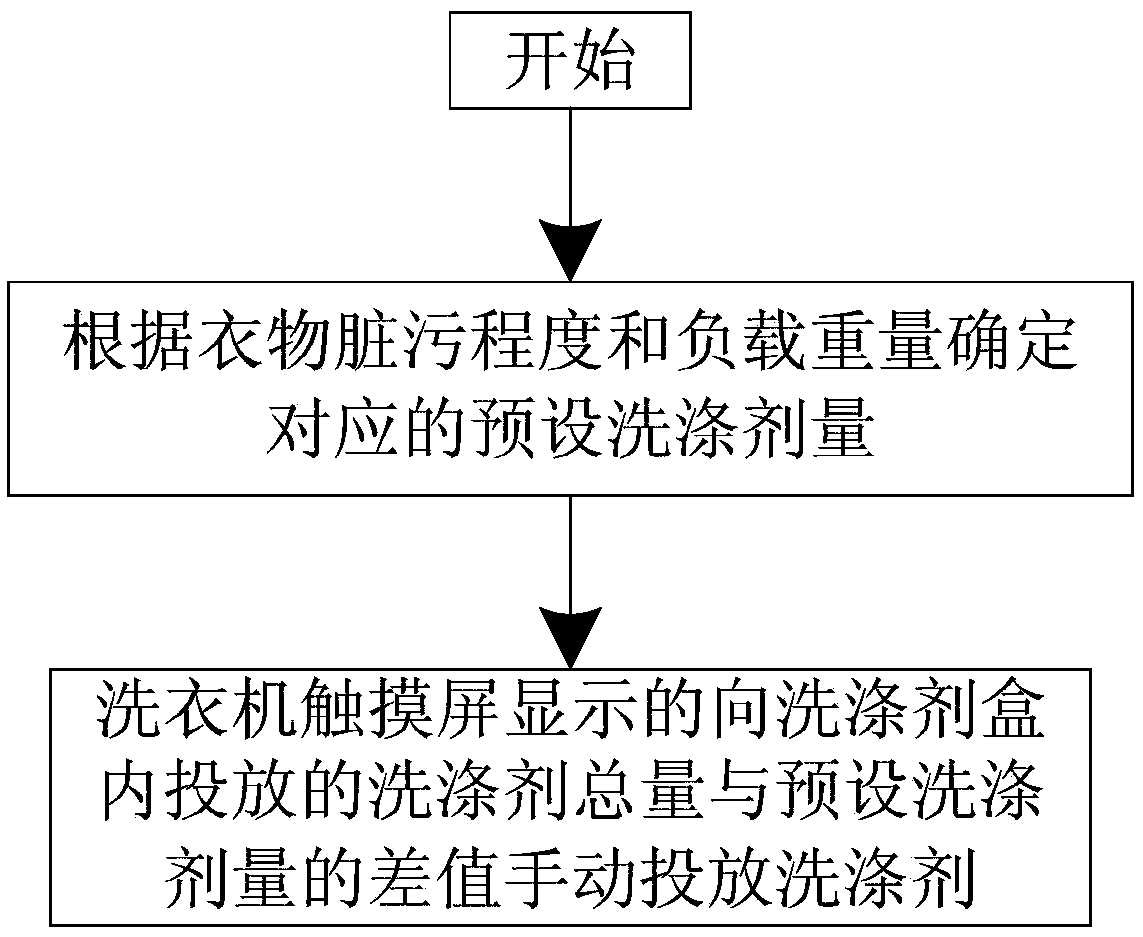

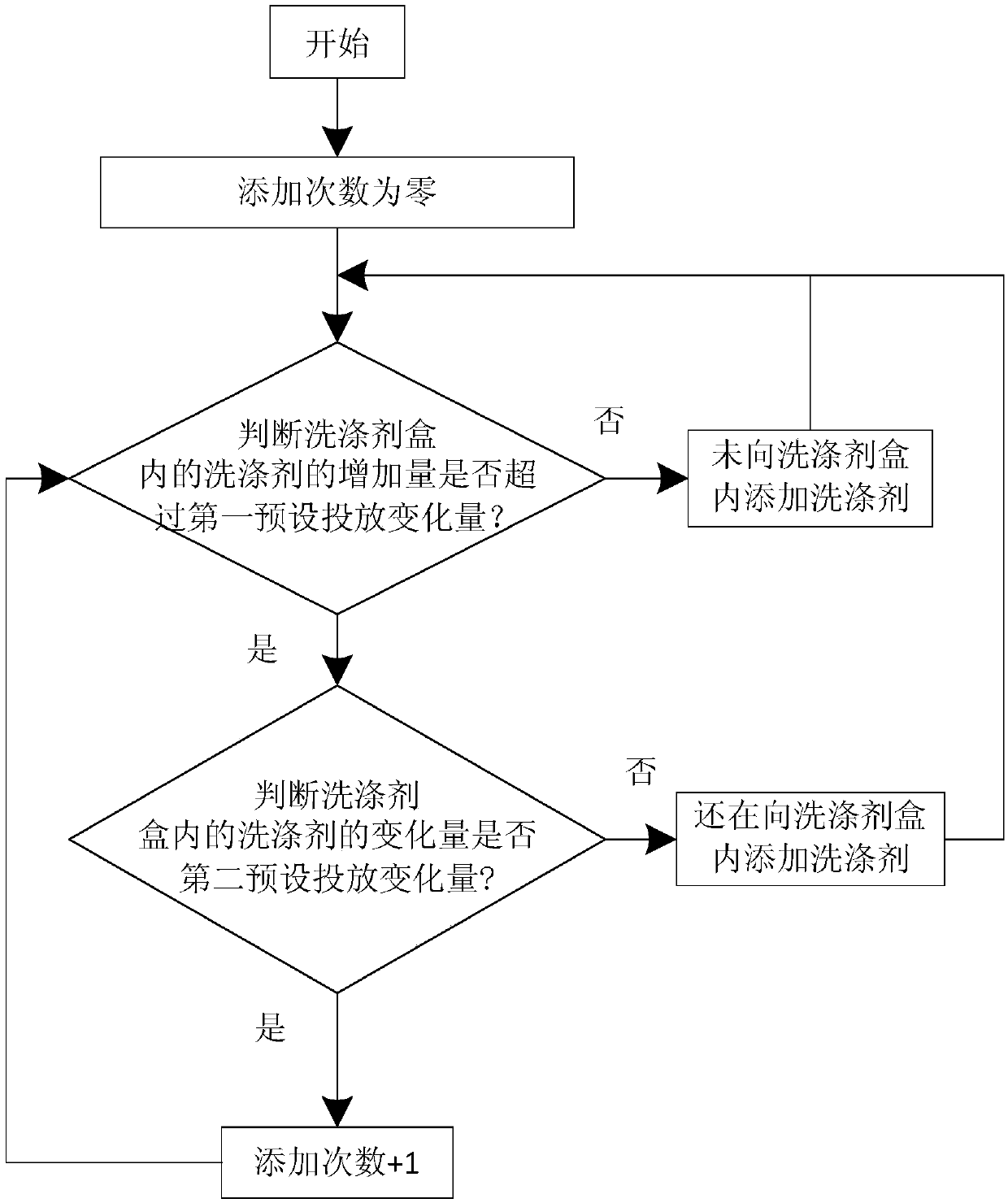

Embodiment 1

[0039] This embodiment provides a control method for manually injecting detergent into washing equipment. The application subject of this method is washing equipment, such as a washing machine, a washing and drying machine, etc., and the detergent includes softener and / or laundry liquid and / or washing powder Wait. In this embodiment, the washing machine is used as the main body of application. figure 1 It is a flow chart of the control method for manually injecting detergent into the washing equipment described in this embodiment, combined below figure 1 The control method for manually injecting detergent into the washing machine washing machine is described in detail, which specifically includes the following steps: determine the corresponding preset detergent amount according to the degree of dirtiness of the clothes and the load weight, and inject the detergent into the detergent box according to the displayed value on the display screen of the washing machine Add detergen...

Embodiment 2

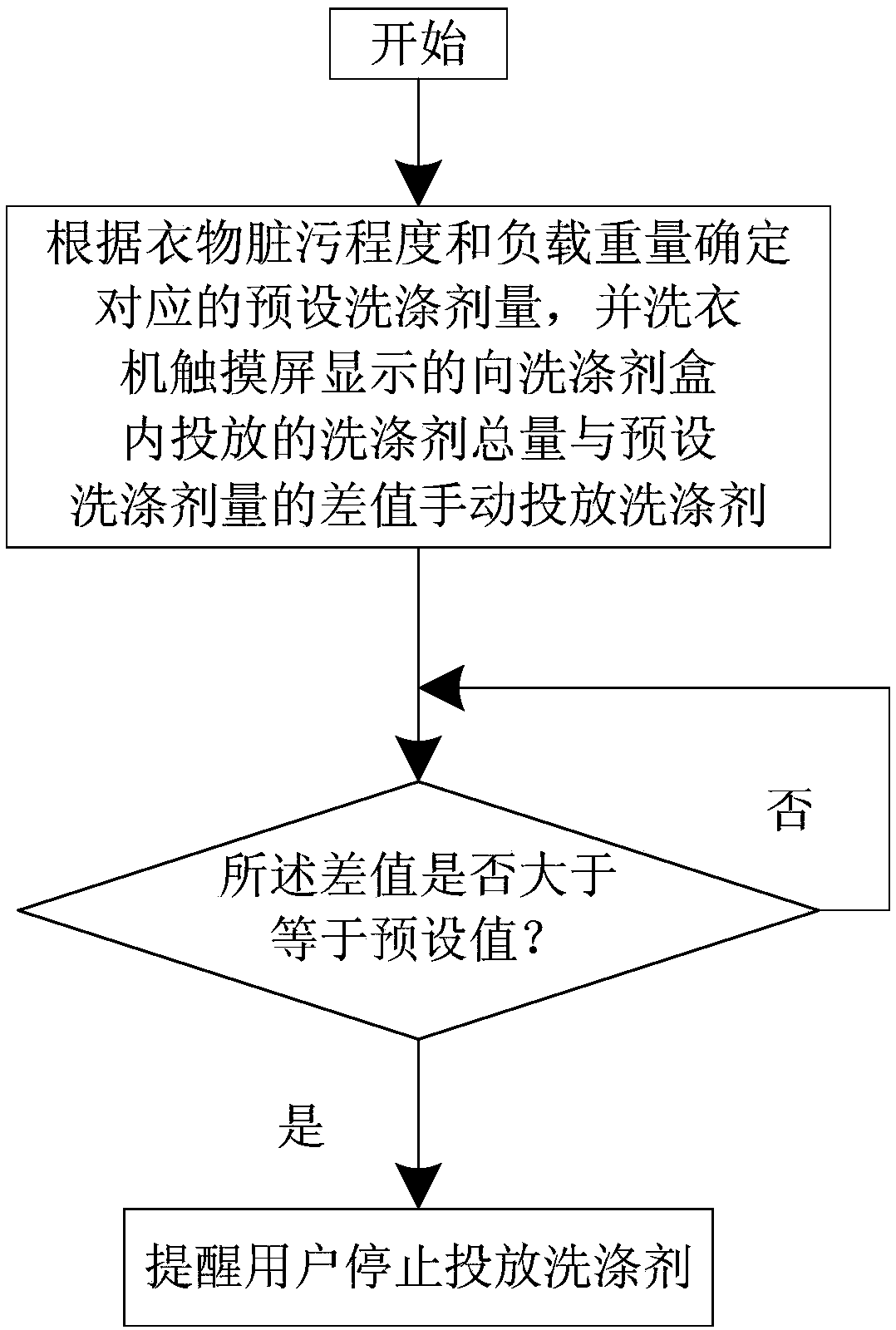

[0047] This embodiment is further optimized on the basis of embodiment one, Figure 4 It is a flow chart of the control method for manually injecting detergent into the washing equipment described in this embodiment, combined below Figure 4 The control method for manually injecting detergent into washing machine washing equipment is described in detail, specifically including the following steps.

[0048] S100. Determine the corresponding preset amount of detergent according to the degree of dirtiness of the clothes and the weight of the load, and manually add detergent according to the difference between the total amount of detergent put into the detergent box displayed on the display screen of the washing machine and the preset amount of detergent.

[0049] In this embodiment, while determining the corresponding preset amount of detergent according to the degree of dirtiness of the clothes and / or the weight of the load, the corresponding preset amount of water inflow is det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com