Backlight module and display device

A backlight module and backplane technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems that light cannot effectively pass through the optical film structure, the camera device cannot effectively capture light, and the optical film structure has low transparency. , to achieve the effect of increasing the camera effect, eliminating the need for opening steps, and improving the uniformity of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

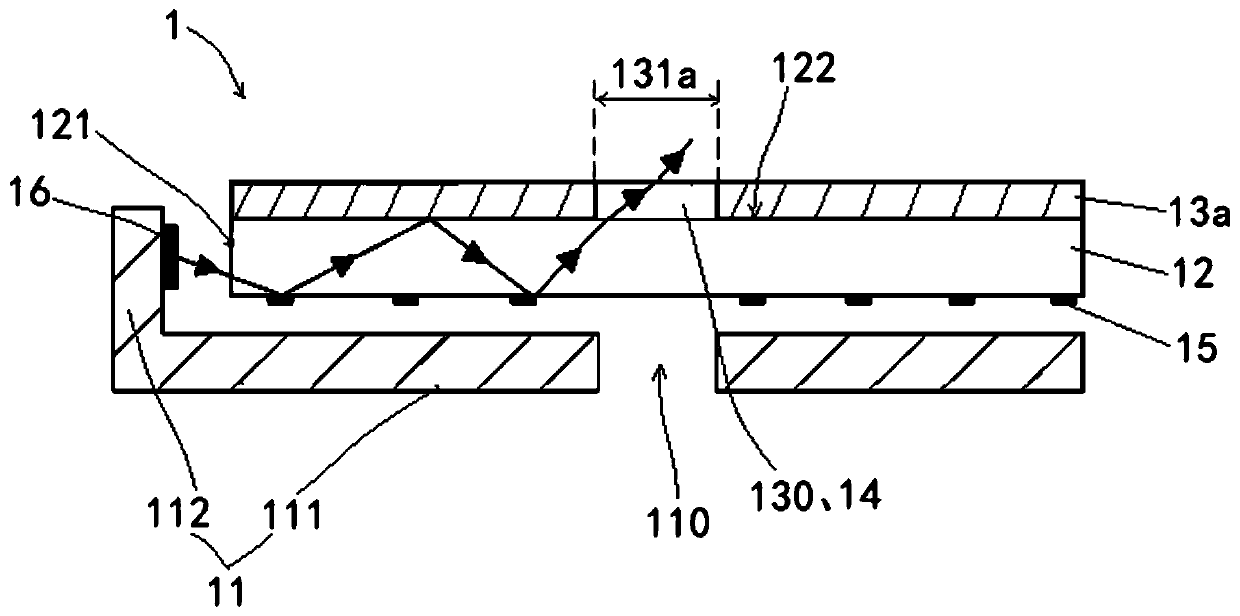

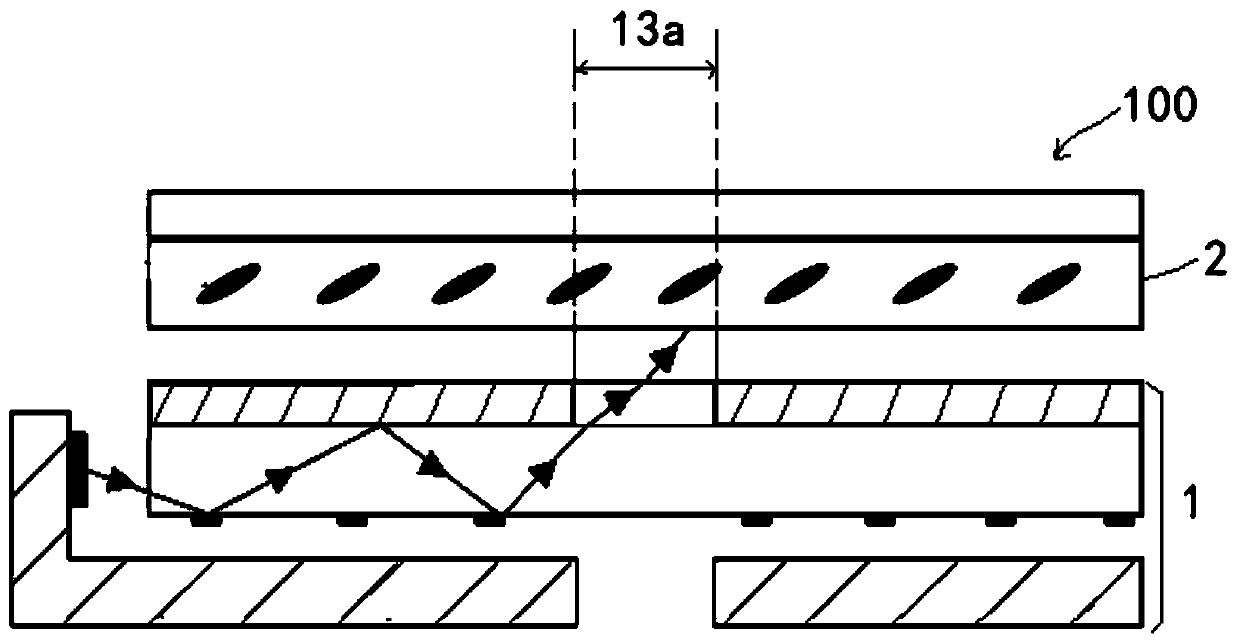

[0033] Such as figure 1 As shown, the backlight module 1 of the present invention includes a backplane 11 , a light guide plate 12 , an optical film 13 a , a transparent film 14 , a reflection sheet 15 and a light source 16 .

[0034] The back plate 11 has a through hole 110 for providing a light-transmitting channel for the camera. The entire backboard 11 includes a bottom board 111 and side boards 112 vertically connected to sides of the bottom board 111 . In this embodiment, the back plate 11 is formed integrally with iron, aluminum or other metals or alloys, and the bottom plate 111 and the side plates 112 form a cavity.

[0035] The light guide plate 12 is disposed in the cavity surrounded by the back plate 11 , specifically, the light guide plate 12 is disposed above the bottom plate 111 in parallel. Wherein the light guide plate 12 has a light incident surface 121 and a light exit surface 122, the side of the light guide plate 12 facing away from the light exit surfac...

Embodiment 2

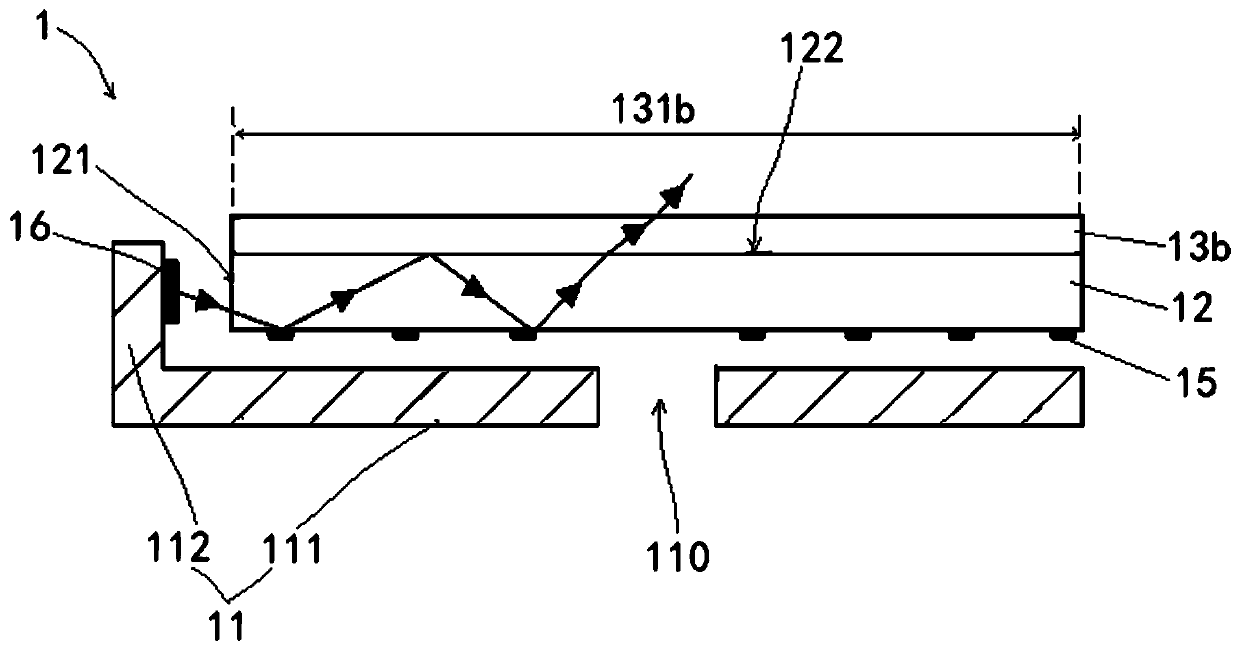

[0046] Such as image 3 As shown, the backlight module 1 of the present invention includes a backplane 11 , a light guide plate 12 , an optical film 13 b , a reflection sheet 15 and a light source 16 .

[0047] The back plate 11 has a through hole 110 for providing a light-transmitting channel for the camera. The entire backboard 11 includes a bottom board 111 and side boards 112 vertically connected to sides of the bottom board 111 . In this embodiment, the back plate 11 is formed integrally with iron, aluminum or other metals or alloys, and the bottom plate 111 and the side plates 112 form a cavity.

[0048] The light guide plate 12 is disposed in the cavity surrounded by the back plate 11 , specifically, the light guide plate 12 is disposed above the bottom plate 111 in parallel. Wherein the light guide plate 12 has a light incident surface 121 and a light exit surface 122, the side of the light guide plate 12 facing away from the light exit surface 122 faces the bottom p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com