Component cleanliness monitoring device and monitoring method

A technology for component cleaning and monitoring devices, applied in the monitoring of photovoltaic systems, electrical components, photovoltaic modules, etc., can solve the problems of uncertain factors and the inability to estimate economic losses, and achieve the effect of clear test results and avoid identification errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

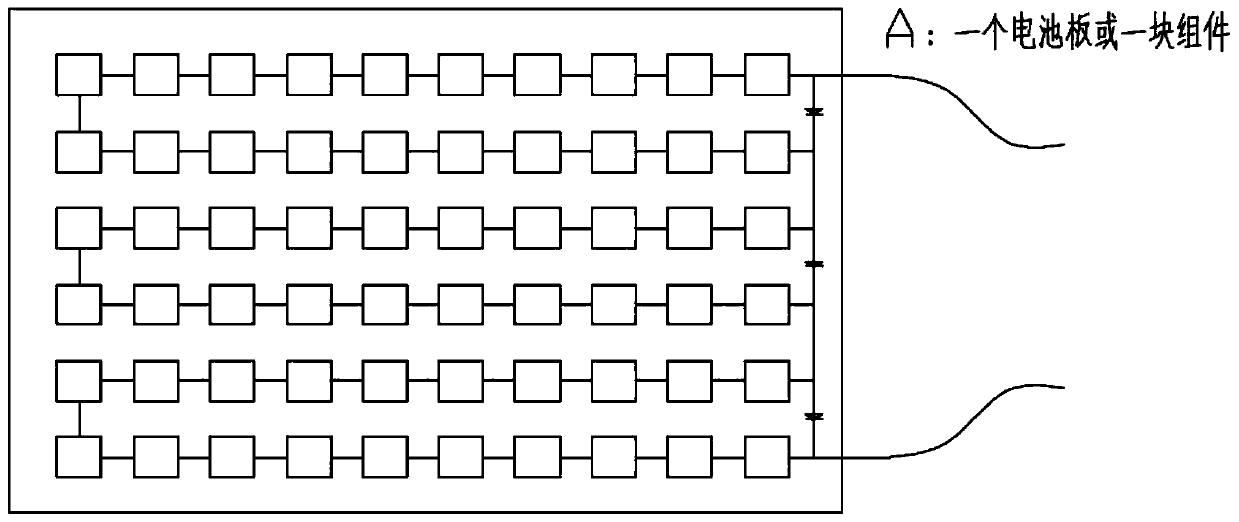

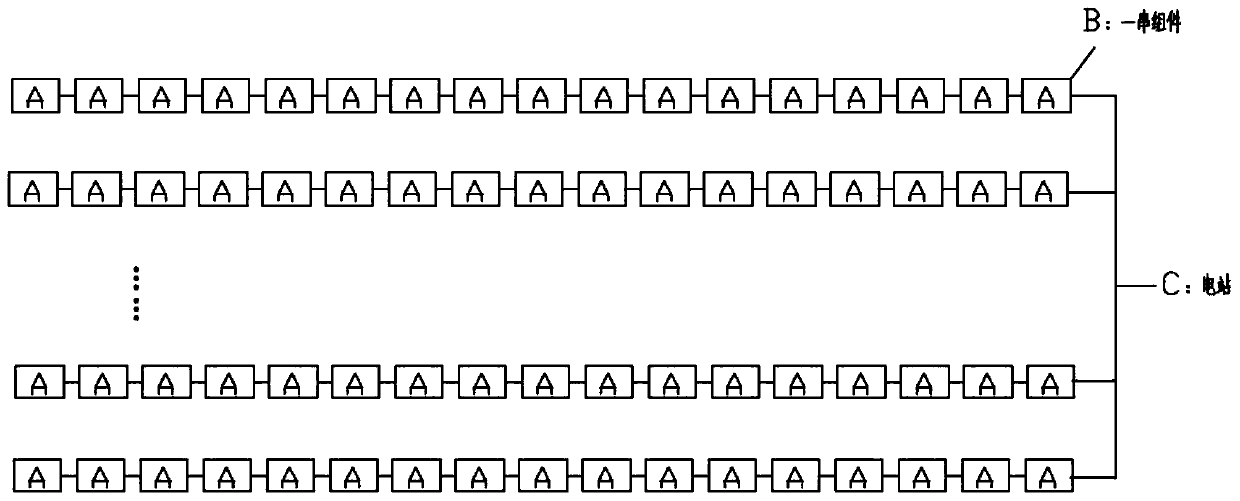

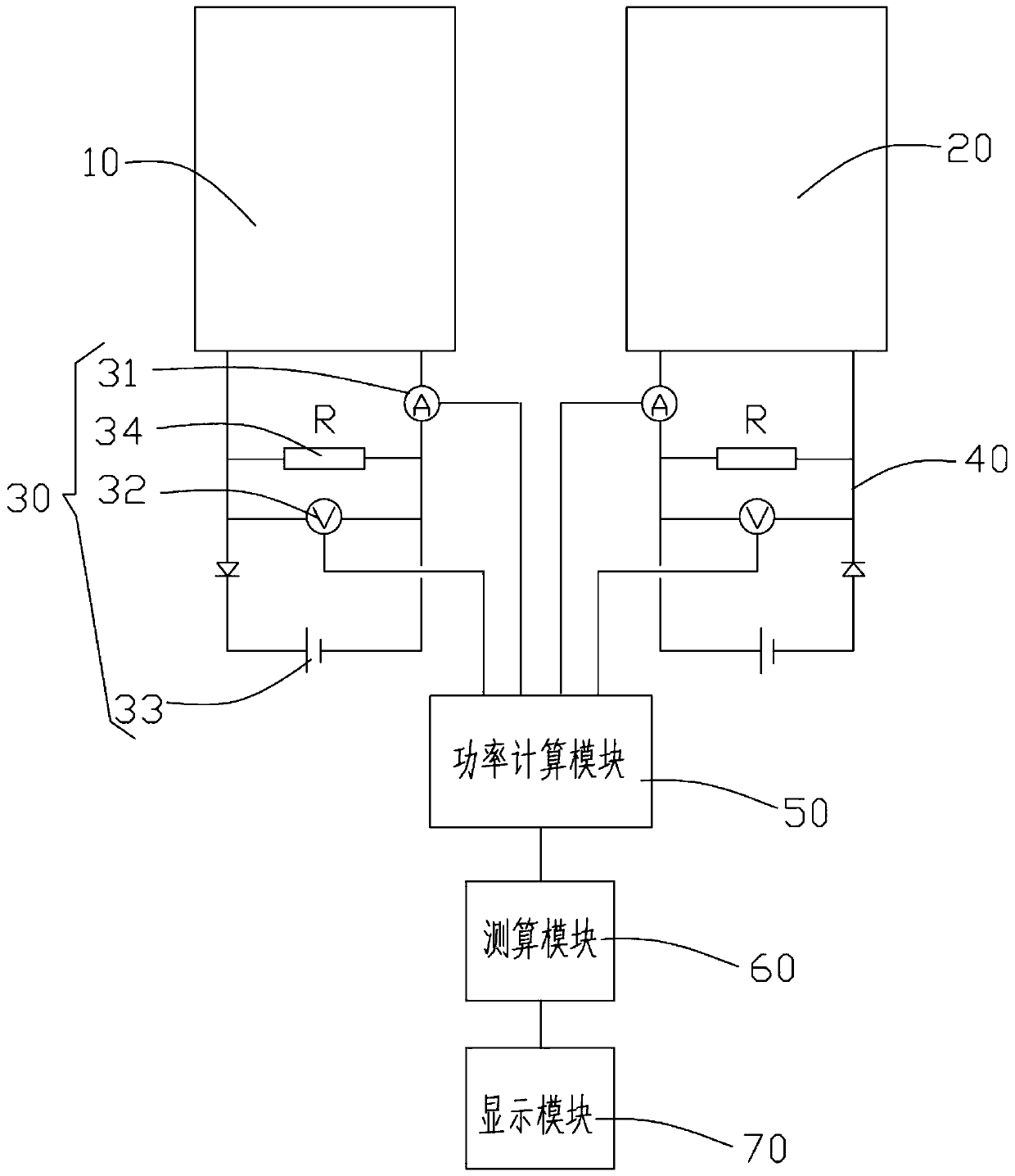

[0027] see Figure 3-6 , an embodiment of the present invention provides a photovoltaic power station cleanliness measurement device, including a reference component 10, a test component 20, a first acquisition module 30, a second acquisition module 40, a power calculation module 50, a measurement module 60, and a display module 70 , the reference assembly 10 and the test assembly 20 are arranged on the ground, the inclination angles and the setting heights of the reference assembly 10 and the test assembly 20 are consistent, the refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com