Suspension type point-plane combined fire extinguishing robot

A fire-extinguishing robot and hanging technology, applied in fire rescue, TV, color TV parts and other directions, can solve the problem of lack of initial fire control function, expand the degree of fire hazards, etc., to reduce transmission paths and prevent fires. The effect of expanding and preventing the spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further introduced below in combination with specific implementation methods and accompanying drawings.

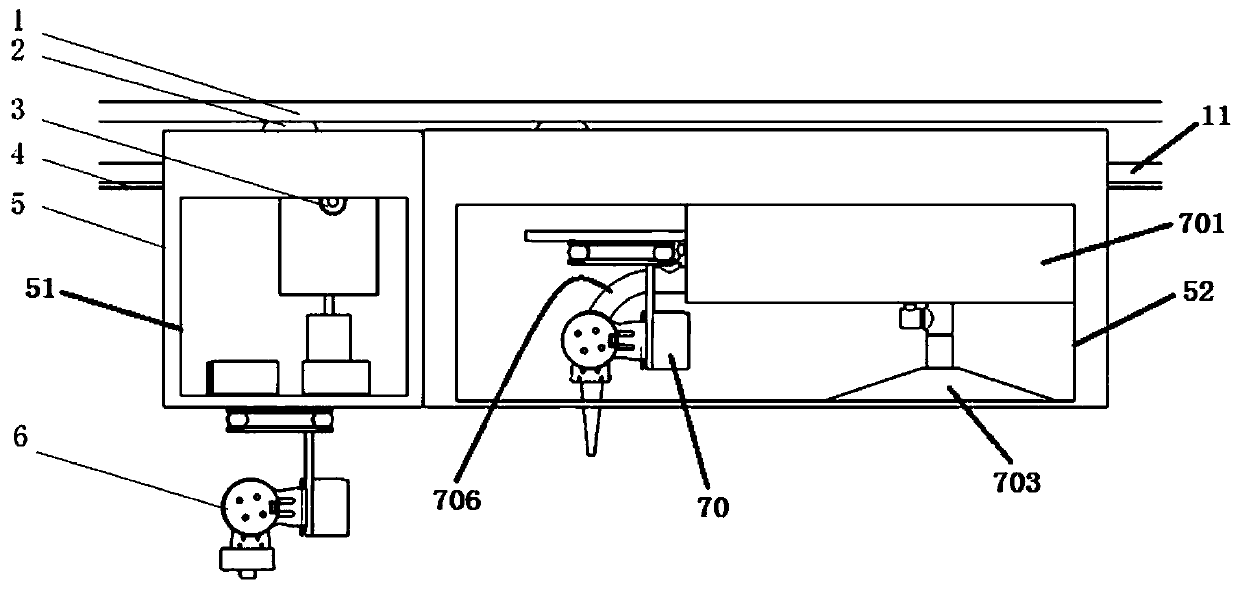

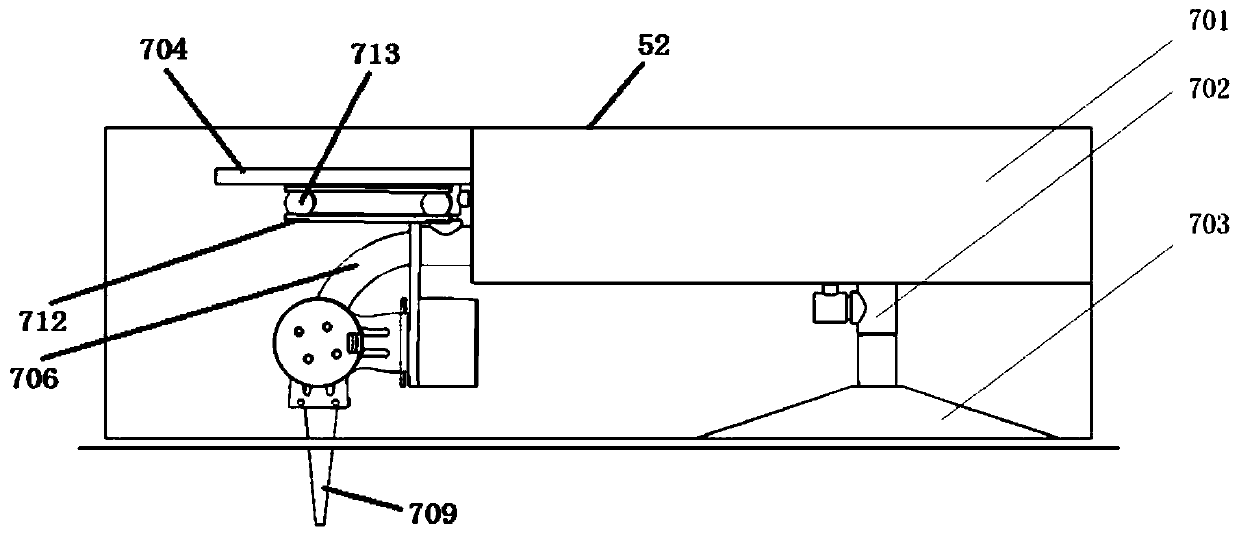

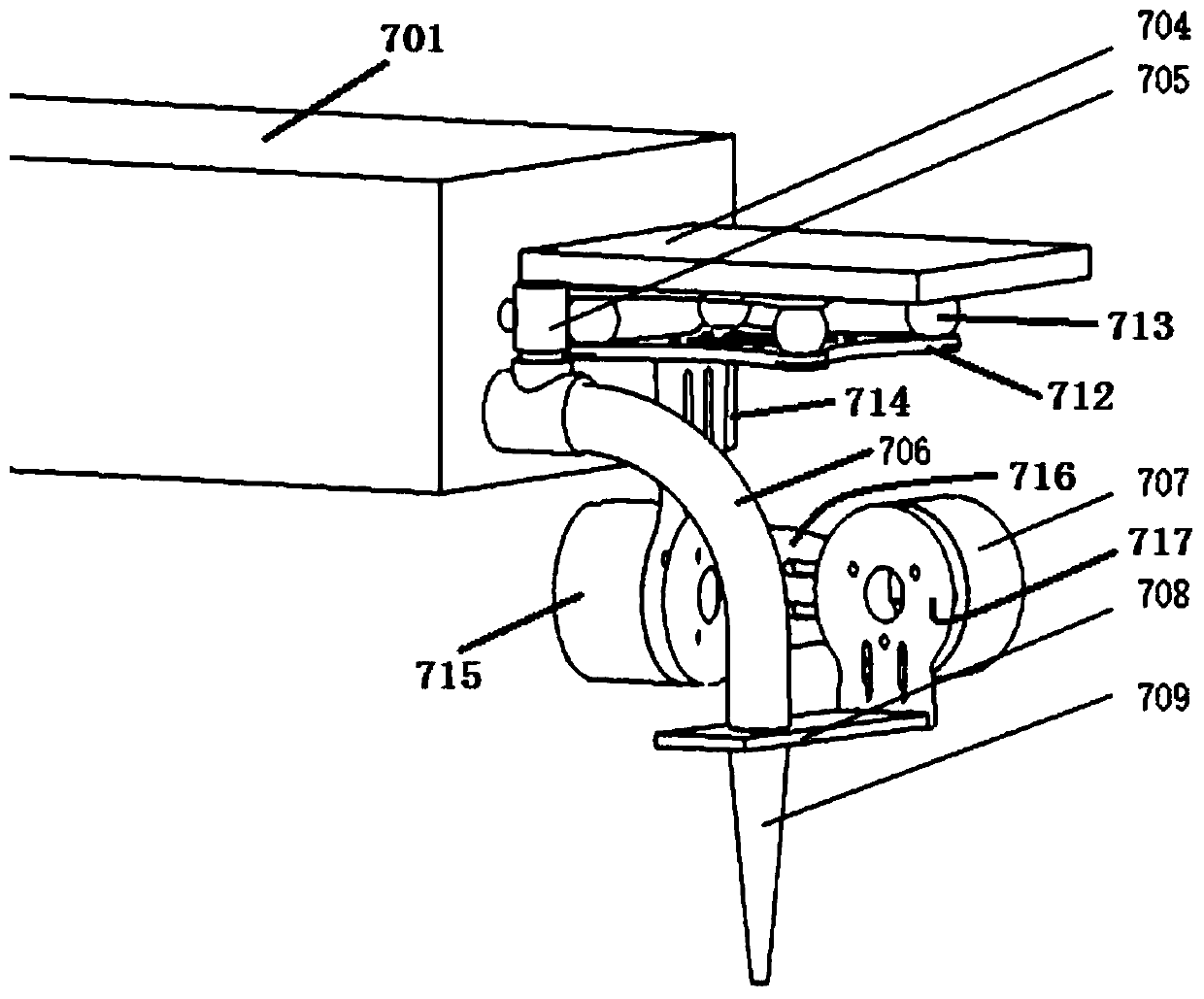

[0025] This specific embodiment discloses a suspended point-surface combination fire extinguishing robot, such as figure 1 Shown, comprise running gear and casing 5. A first box body 51 and a second box body 52 are arranged inside the casing 5 . The bottom of the casing 4 is provided with a first electric pan-tilt 6 , and the first electric pan-tilt 6 is connected with a camera 603 and an infrared thermal imager 604 . A second electric pan-tilt 70 is disposed inside the second box body 52 . The image processing module 506 for processing the signals collected by the camera 603 and the infrared thermal imager 604, the first electromagnetic valve 702 and the second electromagnetic valve in the second box 52 are arranged in the first box body 51. 705 controls the electromagnetic valve control module 503, is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com