Mixer used for fabric coating sizing agent

A coating slurry and mixer technology, applied to mixer accessories, mixers with rotating agitation devices, mixers, etc., can solve the problems of increasing the fabric production process, time-consuming and laborious, etc., to improve mixing efficiency, facilitate mixing, improve The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

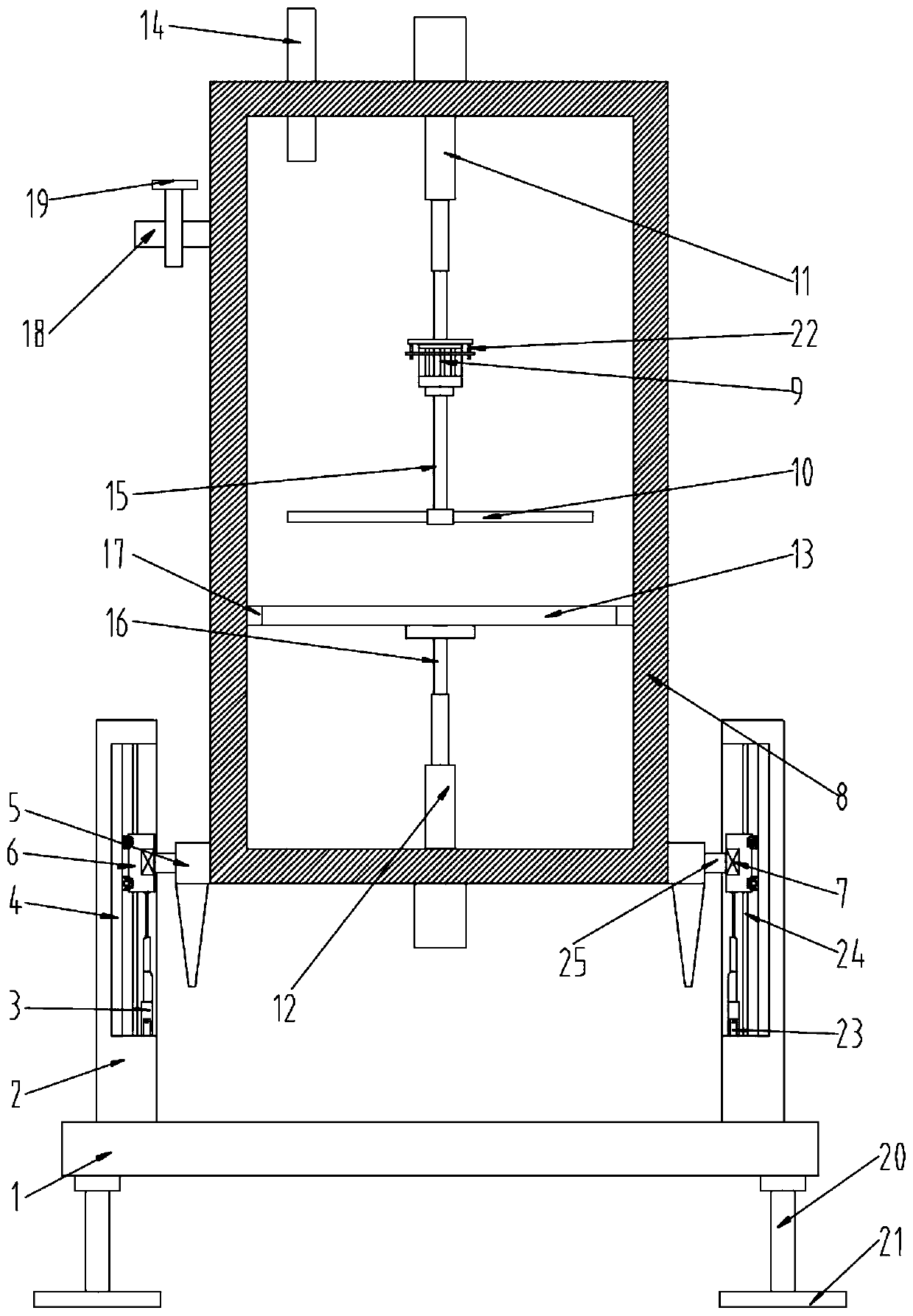

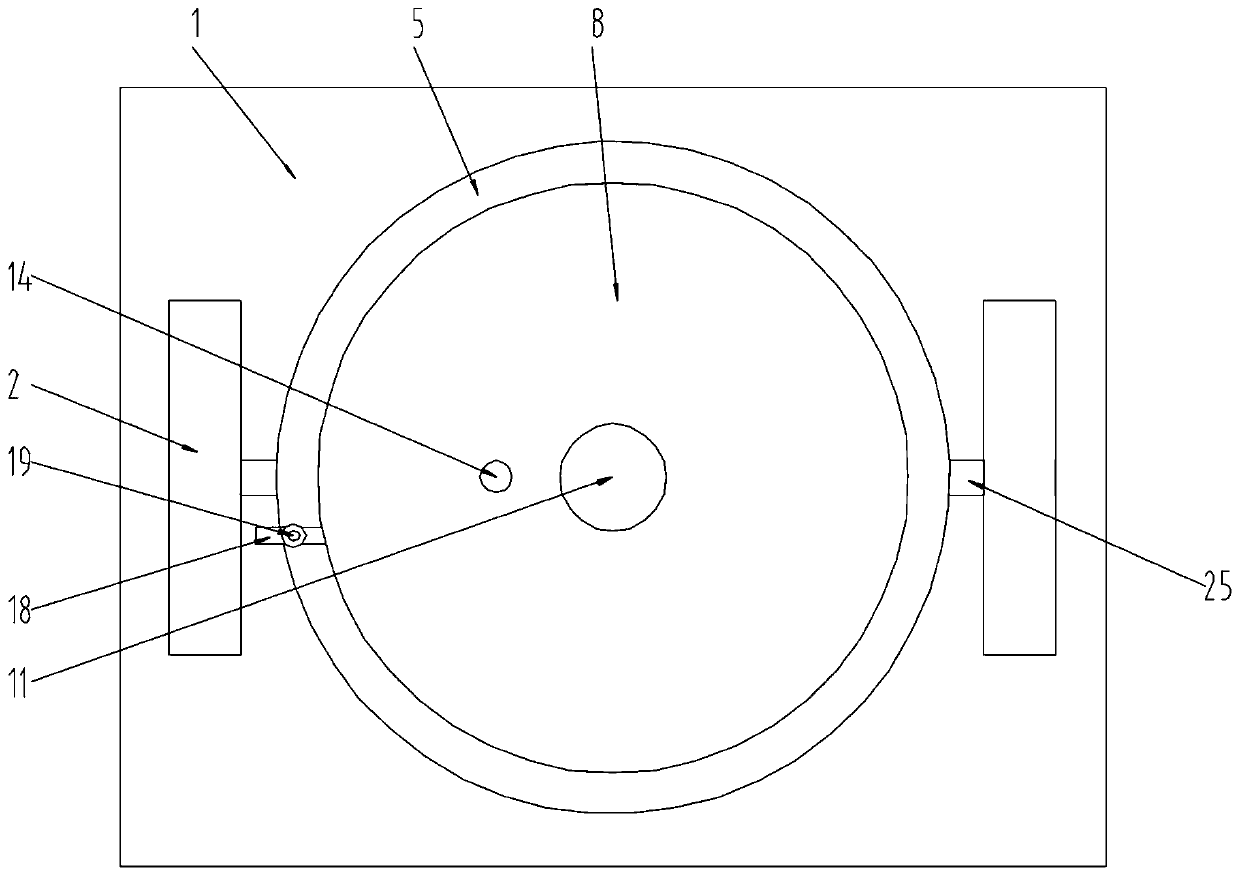

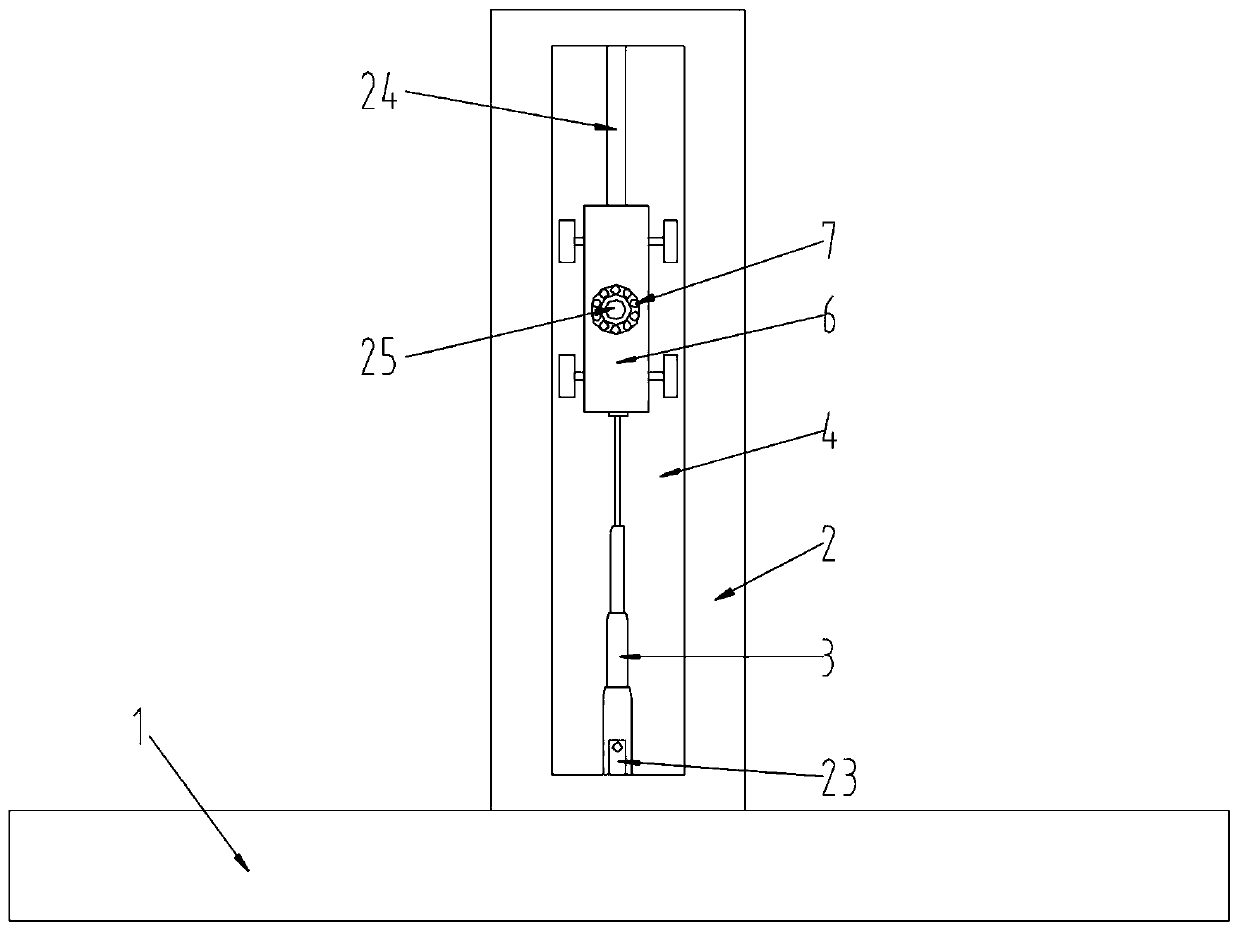

[0024] Embodiment: All electrical components in this case are connected to their adapted power supply through wires by persons skilled in the art, and an appropriate controller should be selected according to the actual situation to meet the control requirements. For the specific connection and control sequence, please refer to the following In the working principle described above, the electrical connection between the electrical parts is completed in sequence. The detailed connection means is a well-known technology in the art. The following mainly introduces the working principle and process, and does not explain the electrical control. When in use, the rectangular A pair of bearings 2 on the base 1 play a supporting role, and are used to support the moving wheel 6 on the strip slide rail 4. The moving wheel 6 can move up and down on the strip slide rail 4, so that the driving end of the telescopic motor 3 can be extended , and the telescopic motor 3 is connected to the movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com