Can conveying adjusting mechanism

An adjustment mechanism and shaft adjustment technology, which is applied to conveyors, transportation and packaging, bottle filling, etc., can solve the problems of difficult adjustment of tank height and flatness, achieve convenient and stable transportation, high adjustment accuracy, and meet the requirements of filling and filling. Delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described below in conjunction with the accompanying drawings.

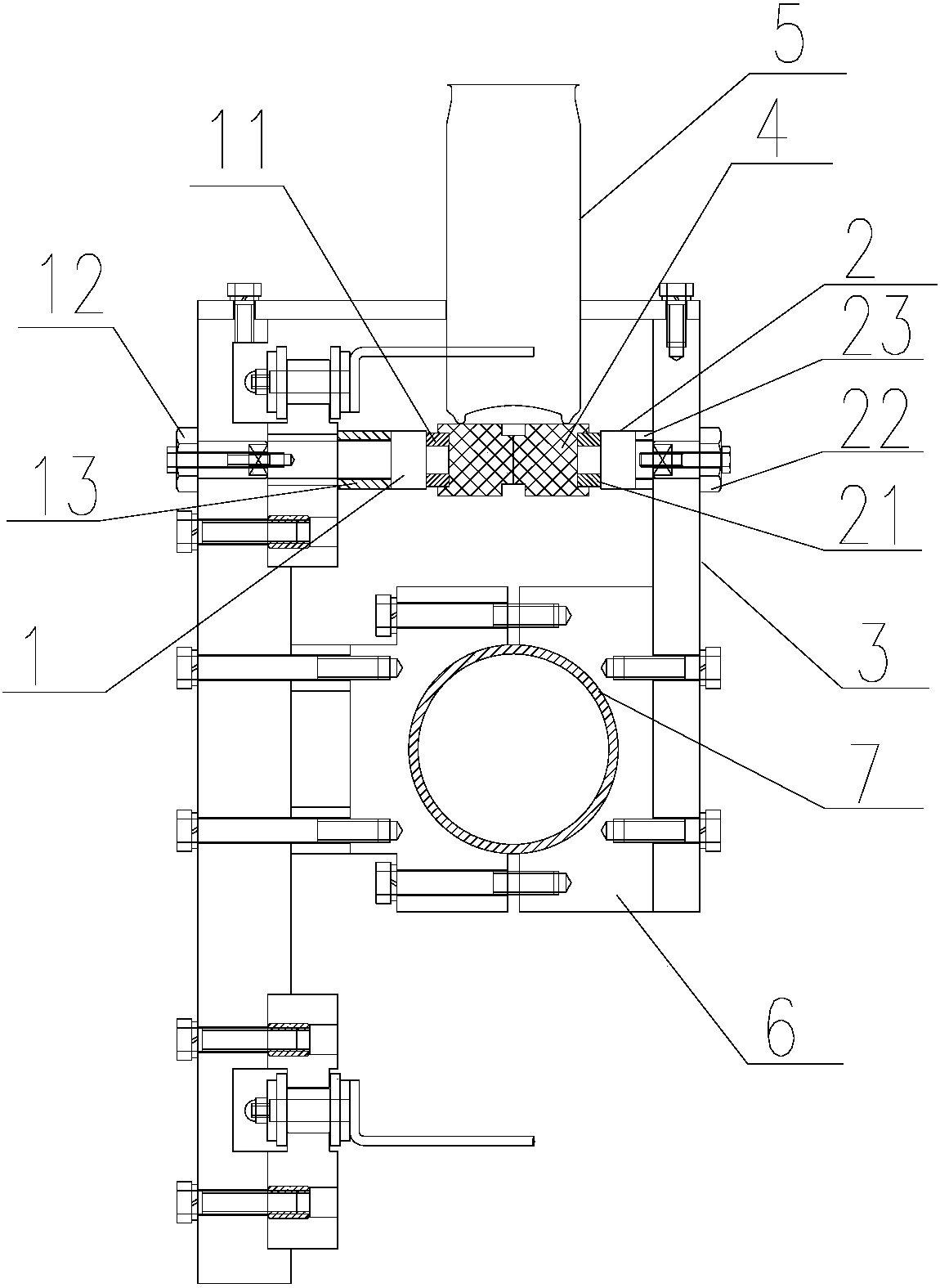

[0020] Such as figure 1 As shown, this embodiment provides a tank transport adjustment mechanism, including a first adjustment shaft 1 and a second adjustment shaft 2 rotatably mounted on a support plate 3, the first adjustment shaft 1 and the second adjustment shaft 2 are respectively located on both sides of the tank conveying plate 4 and are perpendicular to the tank conveying plate 4, the first adjustment block 11 is eccentrically arranged on the end of the first adjustment shaft 1 facing the tank conveying plate 4, and the second adjustment shaft 2 faces One end of the tank conveying plate 4 is eccentrically provided with a second adjusting block 21 , and the first adjusting block 11 and the second adjusting block 21 support the tank conveying plate 4 .

[0021] The tank conveying device includes a support 3, and the support 3 includes left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com