Nested micro-trap structure and preparation method for suppressing secondary electron emission

A technology of secondary electron emission and secondary electrons, which is applied in the field of physical electronics, can solve the problems of limited suppression effect, achieve the effect of increasing micro-discharge threshold, strengthening suppression, and suppressing the total output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

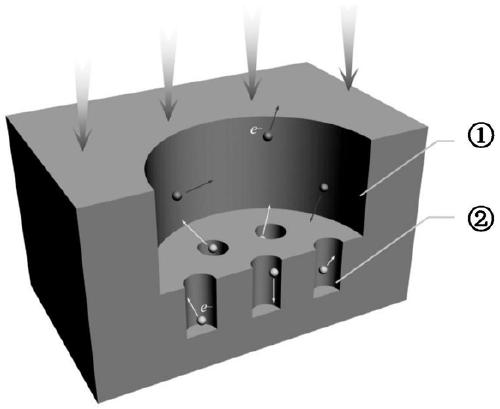

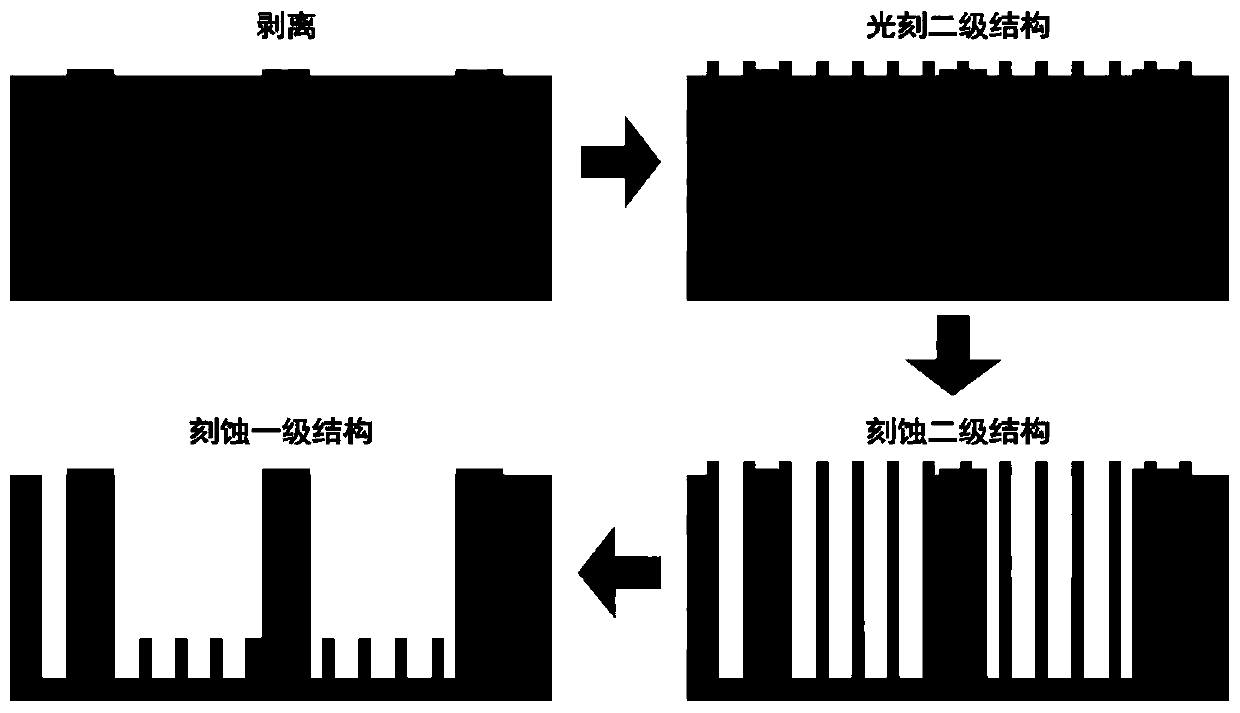

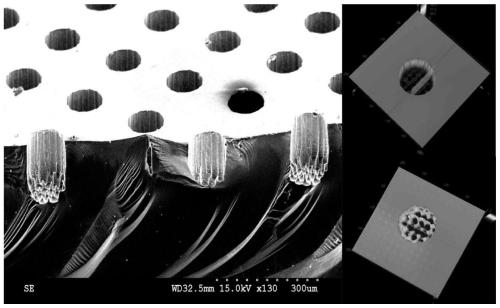

[0027] Such as figure 1 As shown, the nested micro-trap structure disclosed in this embodiment for suppressing secondary electron emission is a double-nested hole structure, and includes several second-level small hole 1 structures in the first-level large hole 1. The first-level large hole 1 is used as the primary trap, and several secondary small hole 1 structures are used as nested traps. The number of structures of the plurality of secondary small holes 1 is determined according to the structural size and duty cycle of the secondary small holes 1 . The overall two-dimensional nested trap structure is configured on the silicon base material, the configuration is a double nested hole structure, and metal sputtering is performed on the double nested hole structure to form a nanoscale film.

[0028] The working method of the nested micro-trap structure for suppressing secondary electron emission disclosed in this embodiment is: when a single initial incident electron is irrad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com