Magnetic electronic building block building module and manufacturing method thereof

An electronic building block and magnetic suction technology, which is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, toys, etc., can solve the problems of complex production process, increased proportion of defective products, inconvenient use, etc., to reduce process complexity performance, convenient installation and production, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

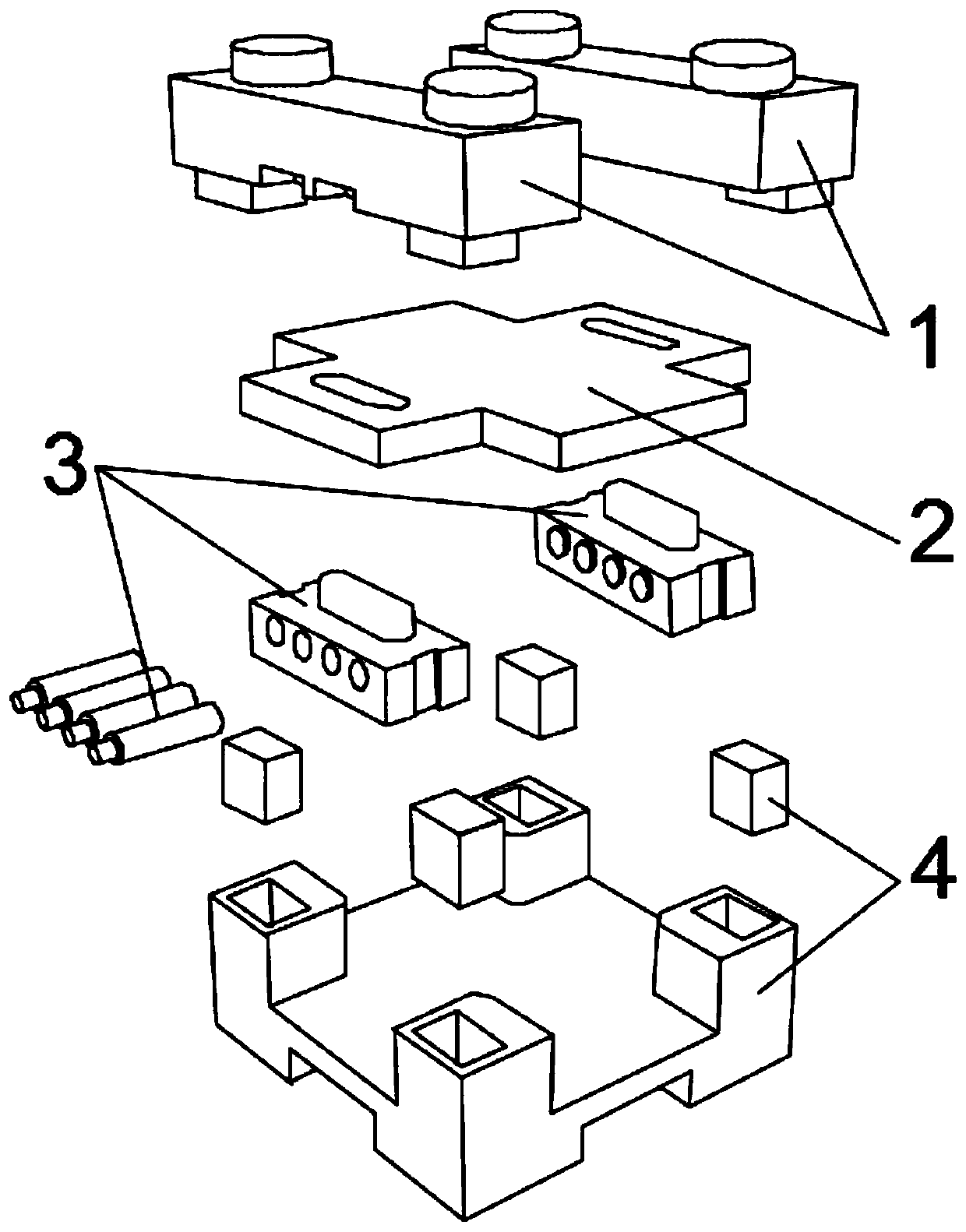

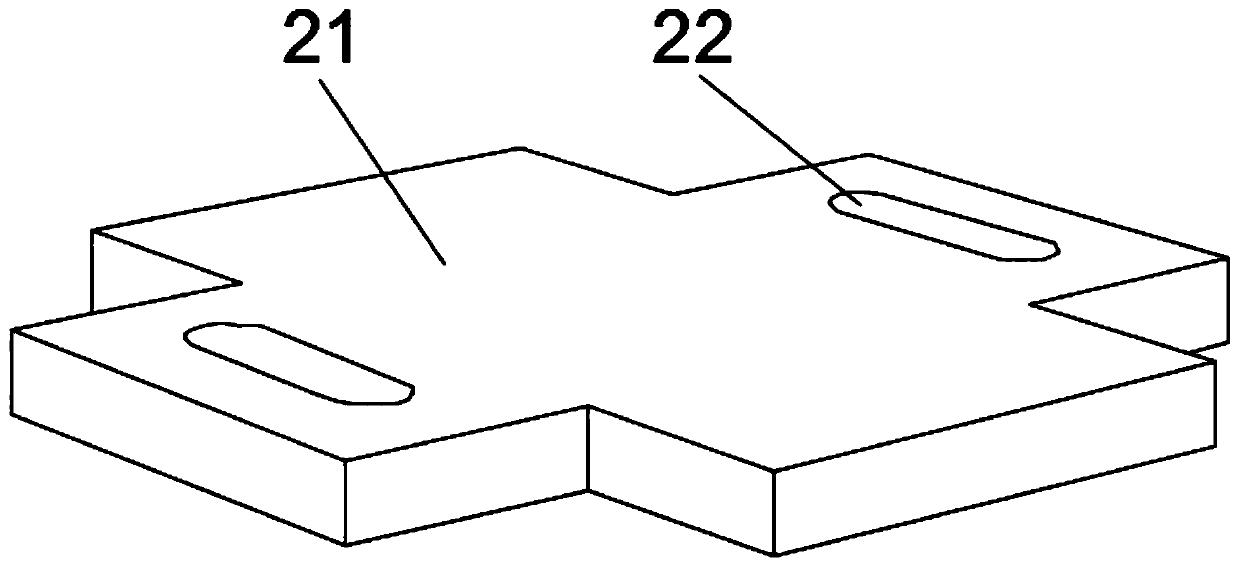

[0029] Such as Figure 1-5 The magnetic suction type electronic building block building module shown includes a circuit board 2, and the circuit board 2 includes a circuit board body 21, and the circuit board body 21 is provided with connecting holes 22, specifically two upper and lower settings and about the circuit board The body 21 is symmetrically arranged through holes; the bottom of the circuit board 2 is equipped with a spring needle holder 3, and the spring needle holder 3 includes a spring female needle holder 31 and a spring male needle holder 32, specifically the spring female needle holder 31 and the spring needle holder 32. A pinhole 33 is provided in the spring male needle holder 32, a spring female needle 36 matched with it is installed in the pinhole 33 of the spring female needle holder 31, and a spring female needle 36 matched with it is installed in the pinhole 33 of the spring male needle holder 32. The spring male needle 34 matched with it, the pinholes 33...

Embodiment 2

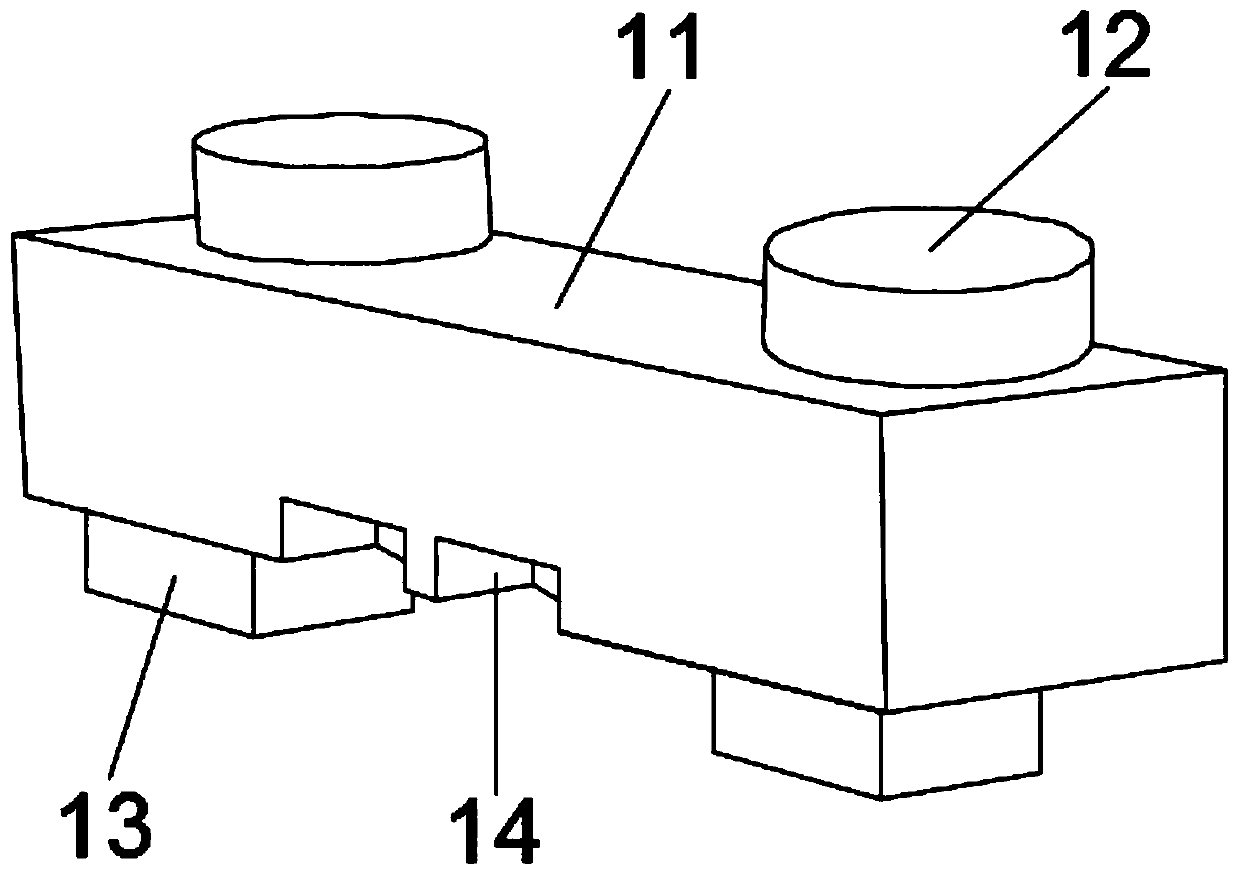

[0031] This embodiment is further optimized on the basis of Embodiment 1. The side of the structural part body 11 is provided with a connection interface 14, which is convenient for left and right (horizontal) connections (interfaces) with other assembled magnetic suction electronic building blocks from the side. It has electrical characteristics) to achieve the function of connecting with other magnetic suction electronic building blocks.

[0032] The upper end of the structural part body 11 is also fixedly equipped with a first connecting protrusion 12, and the bottom of the base plate body 41 is also fixedly installed with a lower base plate protrusion 43, and the bottom of the lower base plate protrusion 43 is provided with a first connecting protrusion. There are 12 matching grooves, and by installing the first connecting protrusion 12 on the upper end of the structural member 1 to match the groove at the bottom of the base plate 4, it is convenient to move up and down (lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com