A high-rise building fire safety power supply equipment

A technology for high-rise buildings and power supply equipment, applied in mechanical equipment, sustainable buildings, wind power generation, etc., can solve problems such as reducing the utilization rate of high-rise building platforms, power supply equipment without external compensation, and fire safety problems in high-rise buildings. The effect of power blank period, novel structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

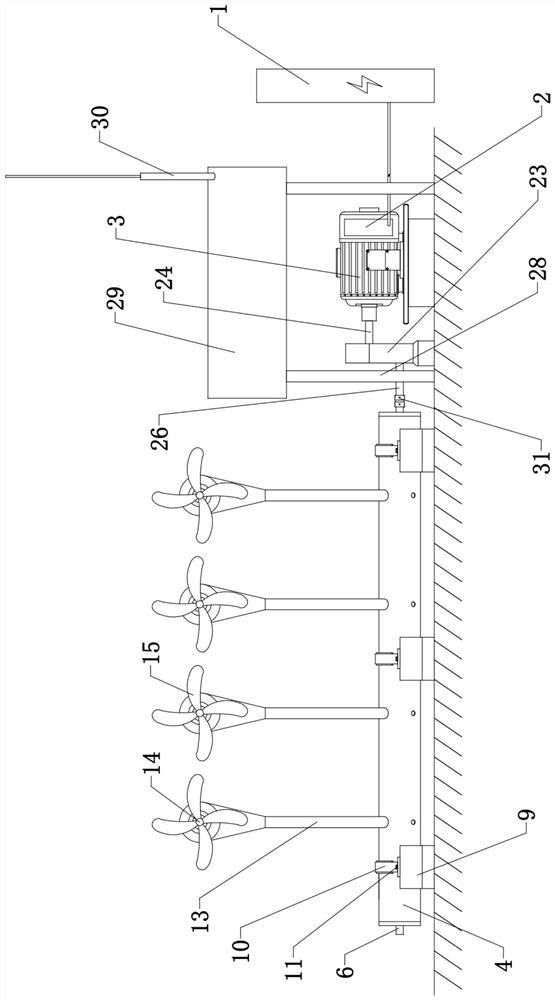

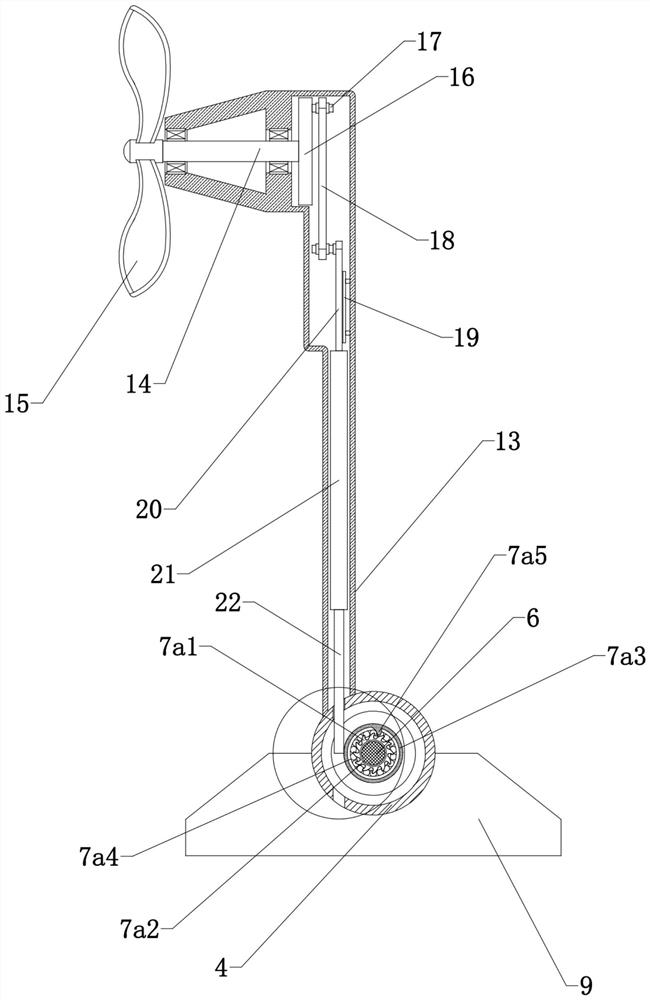

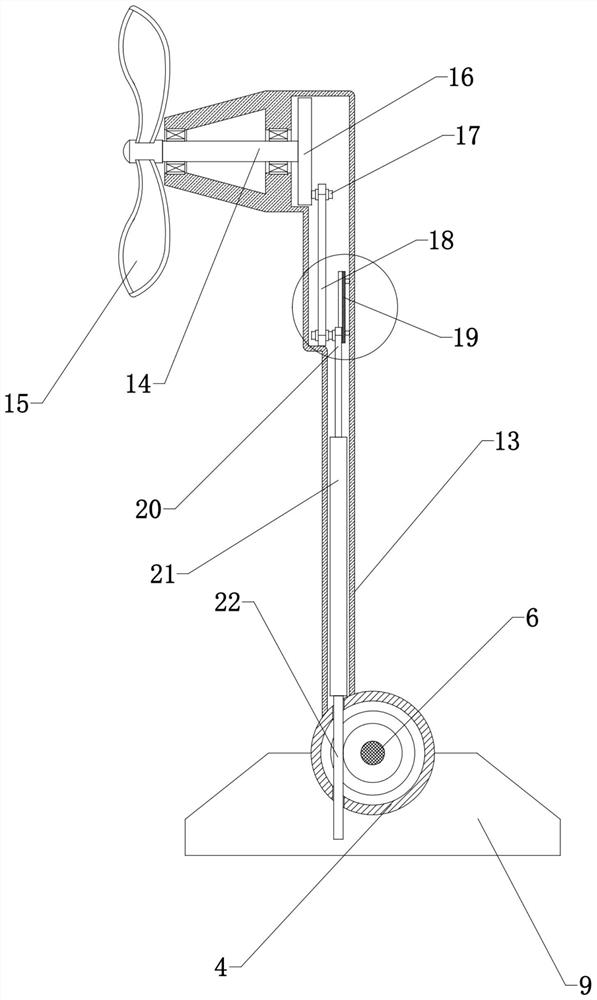

[0039] Embodiment: according to specification Figure 1-10 It can be seen that this case is a high-rise building fire safety power supply equipment, including a backup power supply 1, a voltage stabilizer 2 and a generator set 3, the generator set 3 is installed on the roof, the generator set 3 is connected to a wind power generation unit, and the voltage stabilizer 2 is installed on the On the generator set 3, the backup power supply 1 is installed in the building and connected to the voltage stabilizer 2. In the specific implementation process, the partial energy is converted into mechanical energy through the wind power generation unit, and the mechanical energy is converted into electrical energy through the generator set 3, thereby undergoing voltage stabilization. The regulator 2 stabilizes the voltage and stores the electric energy in the backup power supply 1, which effectively relieves the pressure on the power supply of high-rise buildings;

[0040] The wind power ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com