Novel aluminum profile pasting machine

An aluminum profile and film laminating machine technology, applied in the field of new aluminum profile laminating machines, can solve the problems of film-wrapped aluminum profiles, large outer surface, complex cross-sectional shape, etc., to achieve the effect of improving product phase integrity and prolonging adhesion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

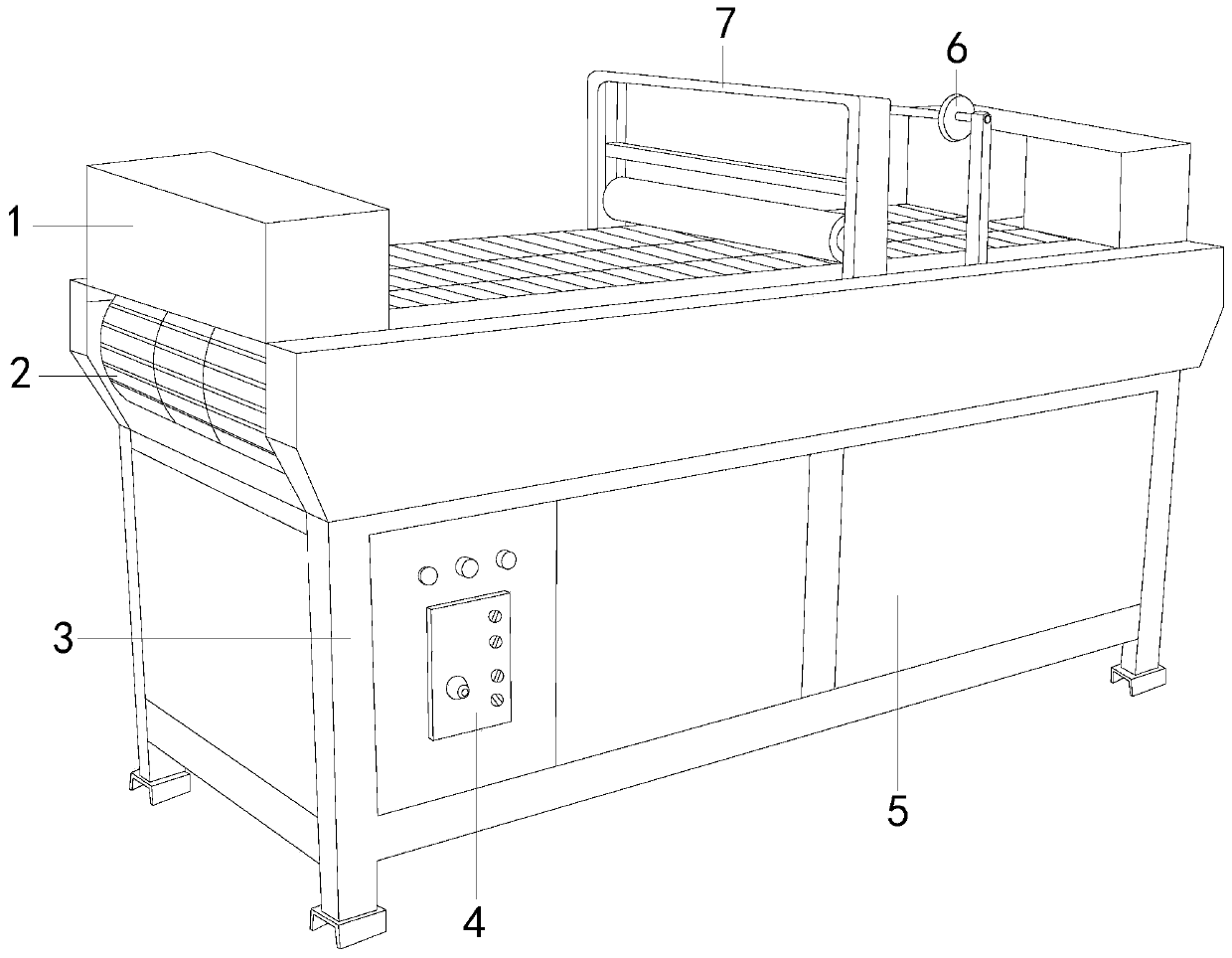

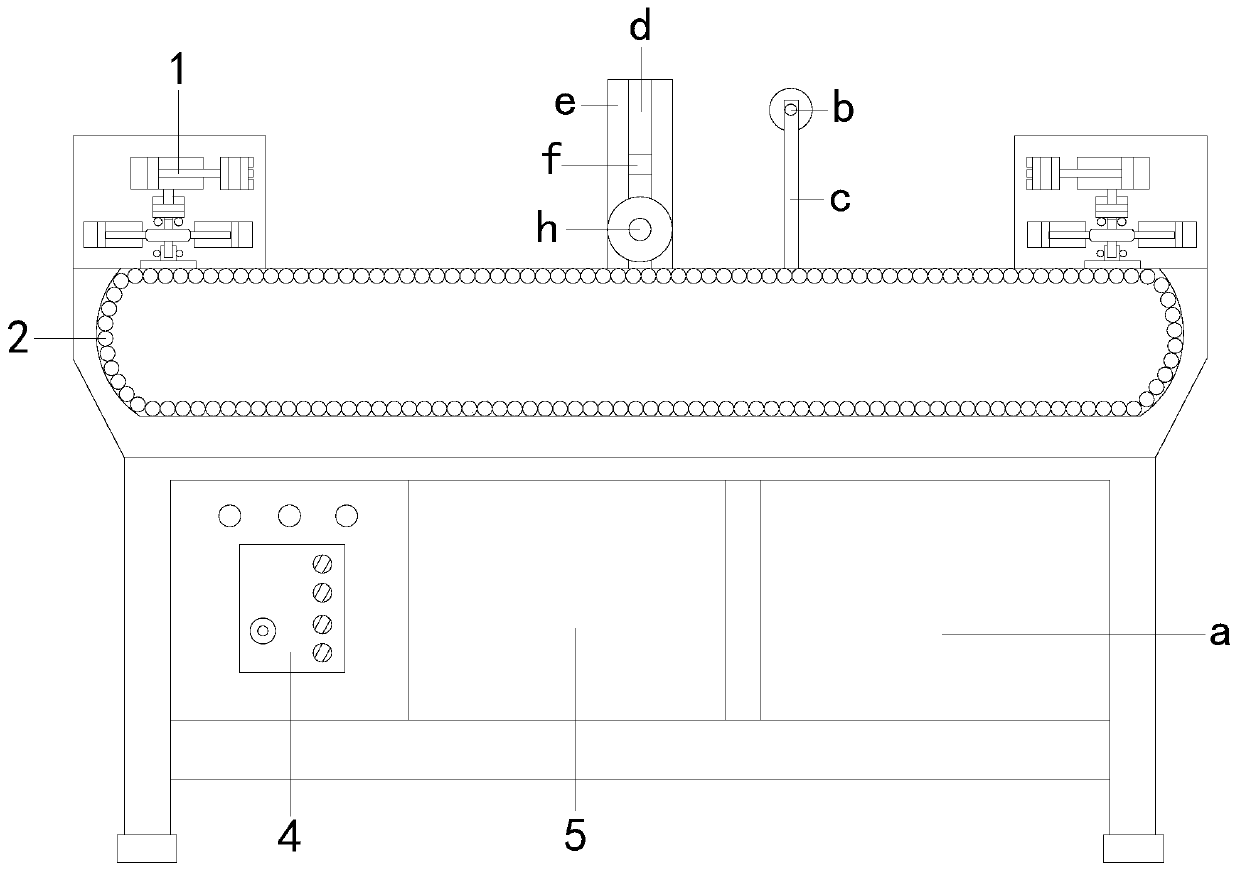

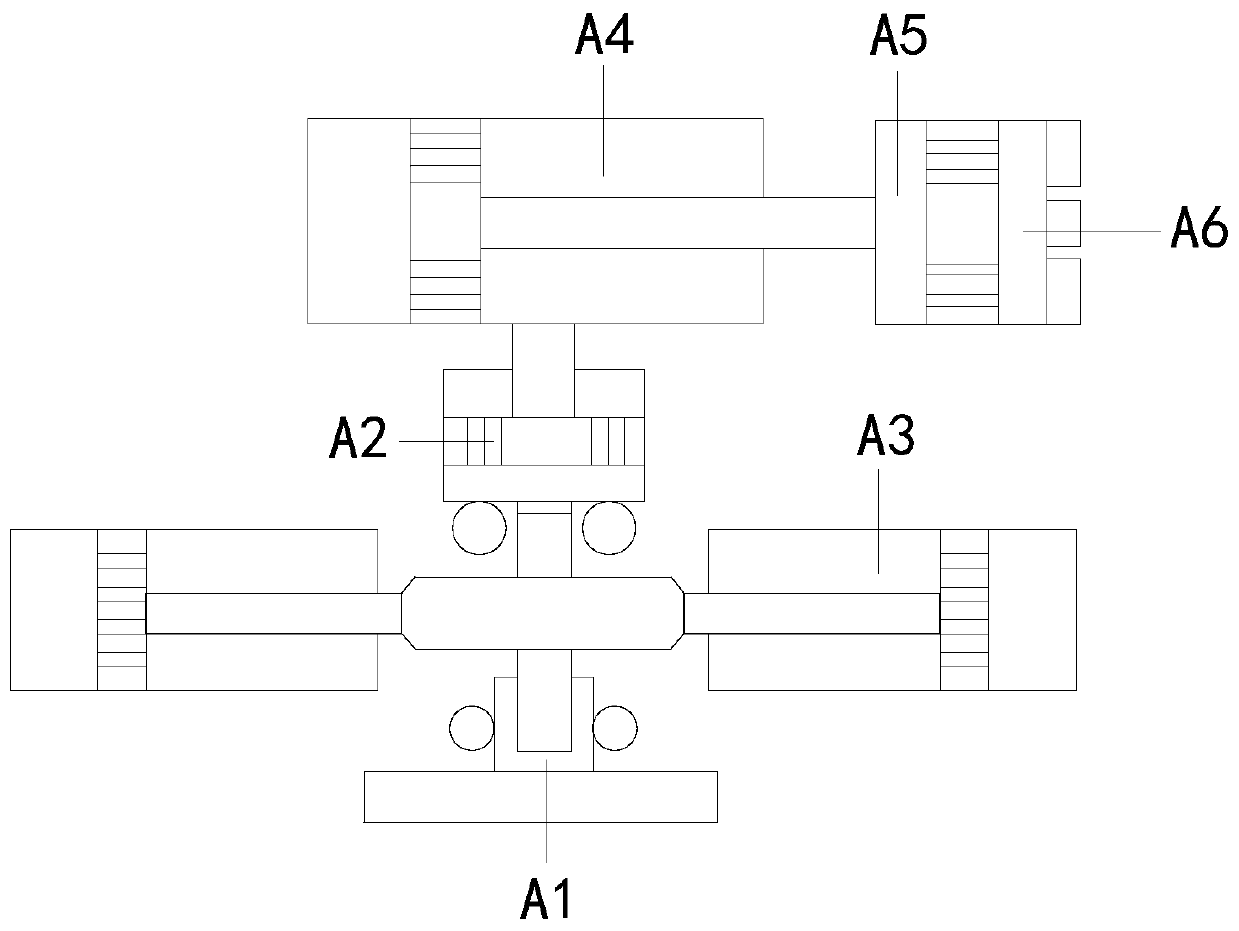

[0022] see figure 1 , the present invention provides a new type of aluminum profile laminating machine, the structure of which includes: a clamping and coating mechanism 1, a conveyor belt 2, a frame 3, an operator 4, a frame plate 5, an adjustment rod 6, and a rolling frame 7. The clamping and covering mechanism 1 is set on both sides of the surface of the conveyor belt 2, the conveyor belt 2 is connected to the frame 3, the bottom side of the frame 3 is provided with an operator 4 and a shelf plate 5, and the adjustment rod 6 is set on the surface of the frame 3 , the frame 3 is connected with the rolling frame 7, the middle section of the conveyor belt 2 is in a concave state, and the overall structure is an annular belt, and the frame 3 is the basic structure frame of the film laminating machine, which not only plays a bearing role for the connection of other components, but also It also plays the function of weighing and pressing, and the good load-bearing performance ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com