Mechanical pointer pressure gauge reading identification method

A recognition method and pressure gauge technology, applied in character and pattern recognition, computer parts, instruments, etc., can solve problems such as difficult to guarantee the accuracy of readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

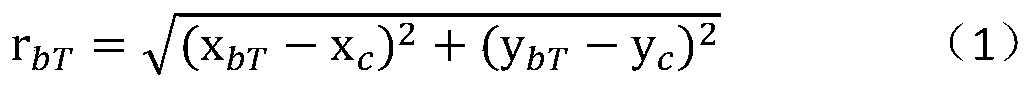

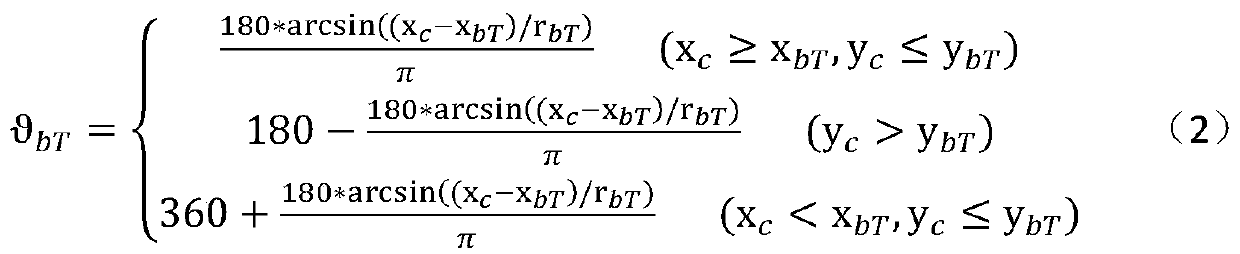

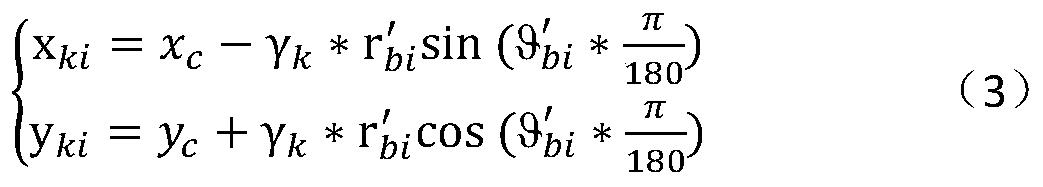

[0095] Embodiment: a kind of mechanical pointer pressure gauge reading recognition method, comprises the following steps:

[0096] (1) Take the original color image of the mechanical pointer pressure gauge through the camera;

[0097] (2) Obtain the dial image of the mechanical pointer pressure gauge from the original color image, the specific process is:

[0098] 2.1 Grayscale the original color image to obtain the initial grayscale image;

[0099] 2.2 Perform Gaussian filtering and median filtering sequentially on the initial grayscale image to obtain an intermediate grayscale image;

[0100] 2.3 Construct a two-dimensional coordinate system, and place the intermediate grayscale image in the two-dimensional coordinate system;

[0101] 2.4 Set the input parameter range of the Hough transform to F H‘’ *f H‘’ *1.1-F H‘’ *f H‘’ *0.90, where F H‘’ The value is the width resolution of the image captured by the camera, that is, the number of width pixels, f H‘’ The value ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com