Molten carbonate fuel cell and calcium circulation integration system and method

A molten carbonate, fuel cell technology, applied in the direction of molten electrolyte fuel cells, fuel cells, circuits, etc., can solve the problems of low energy utilization rate, high energy consumption, low power generation efficiency, etc., to avoid the increase of primary energy consumption , avoid the loss of power generation efficiency, the effect of mitigating climate change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

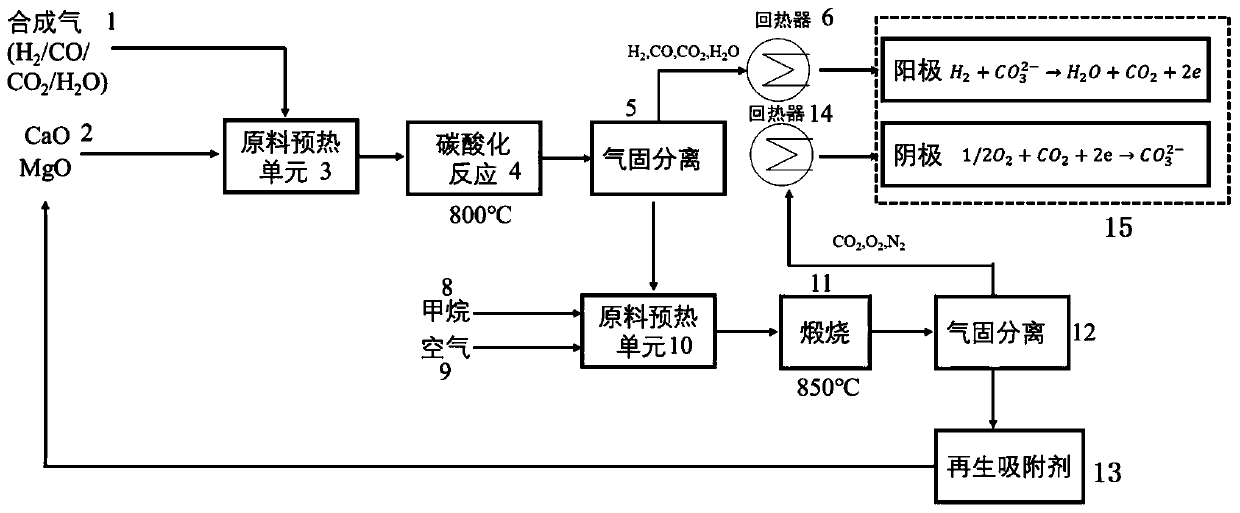

[0032] see figure 1 As shown, the present invention provides a structure of a molten carbonate fuel cell and calcium circulation integrated system, including: a synthesis gas unit 1, a raw material unit 2, a first raw material preheating unit 3, a carbonation reaction unit 4, a first gas Solid separator 5, second raw material preheating unit 10, calciner reactor 11, second gas-solid separator 12, regeneration adsorbent generation unit 13, first regenerator 6, second regenerator 14 and molten carbon salt fuel cell15.

[0033] The output ports of the synthesis gas unit 1 and the raw material unit 2 are connected to the inlet of the first raw material preheating unit 3; the outlet of the first raw material preheating unit 3 is connected to the inlet of the carbonation reaction unit 4; the outlet of the carbonation reaction unit 4 is connected to the first The inlet of the gas-solid separator 5 and the gas outlet of the first gas-solid separator 5 communicate with the anode of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com