Installation device and installation method

A technology of an installation device and an installation method, applied in the directions of electrical components, electrical components, etc., can solve the problems of positional deviation, difficult-to-insert parts, protruding insertion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

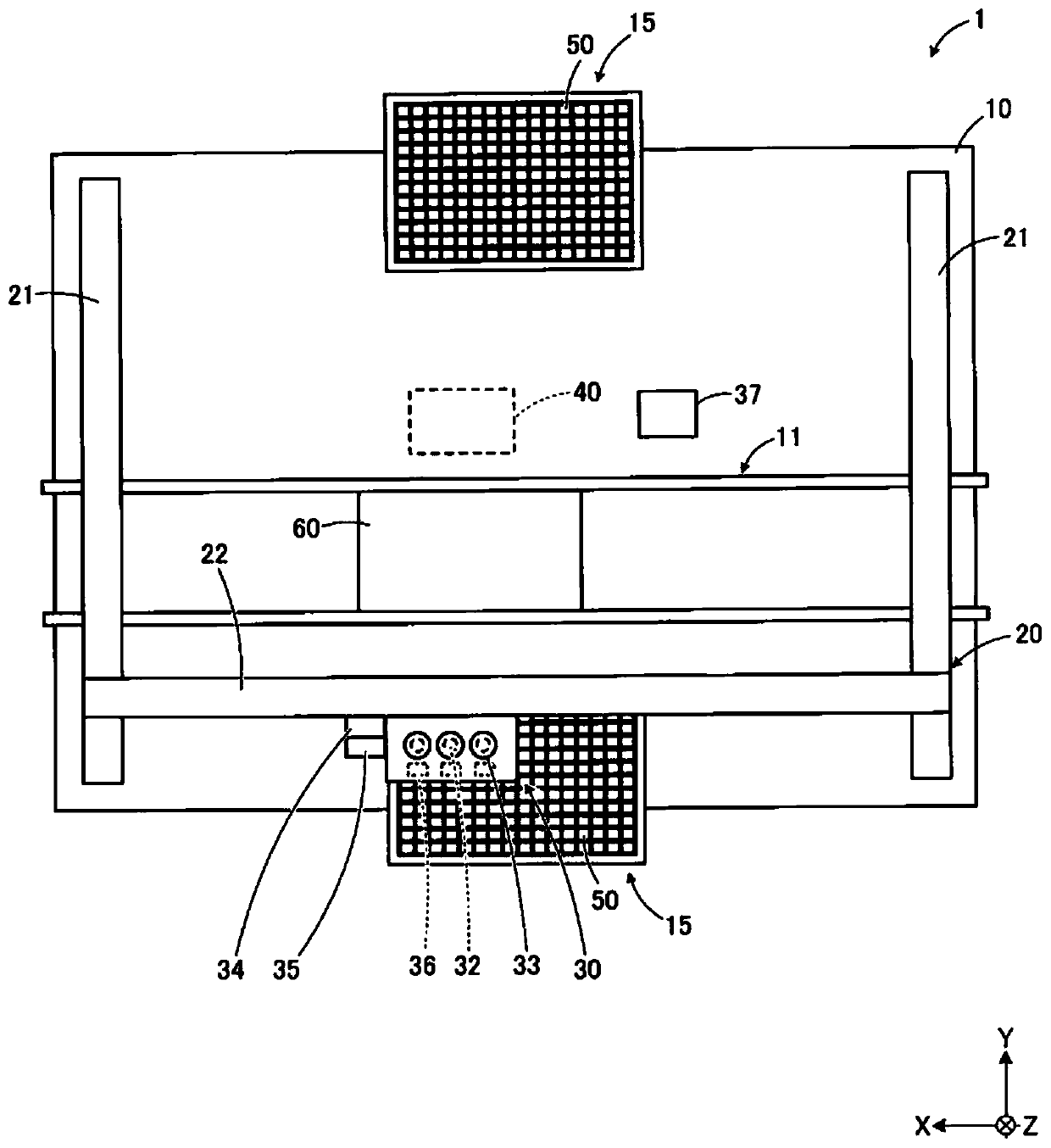

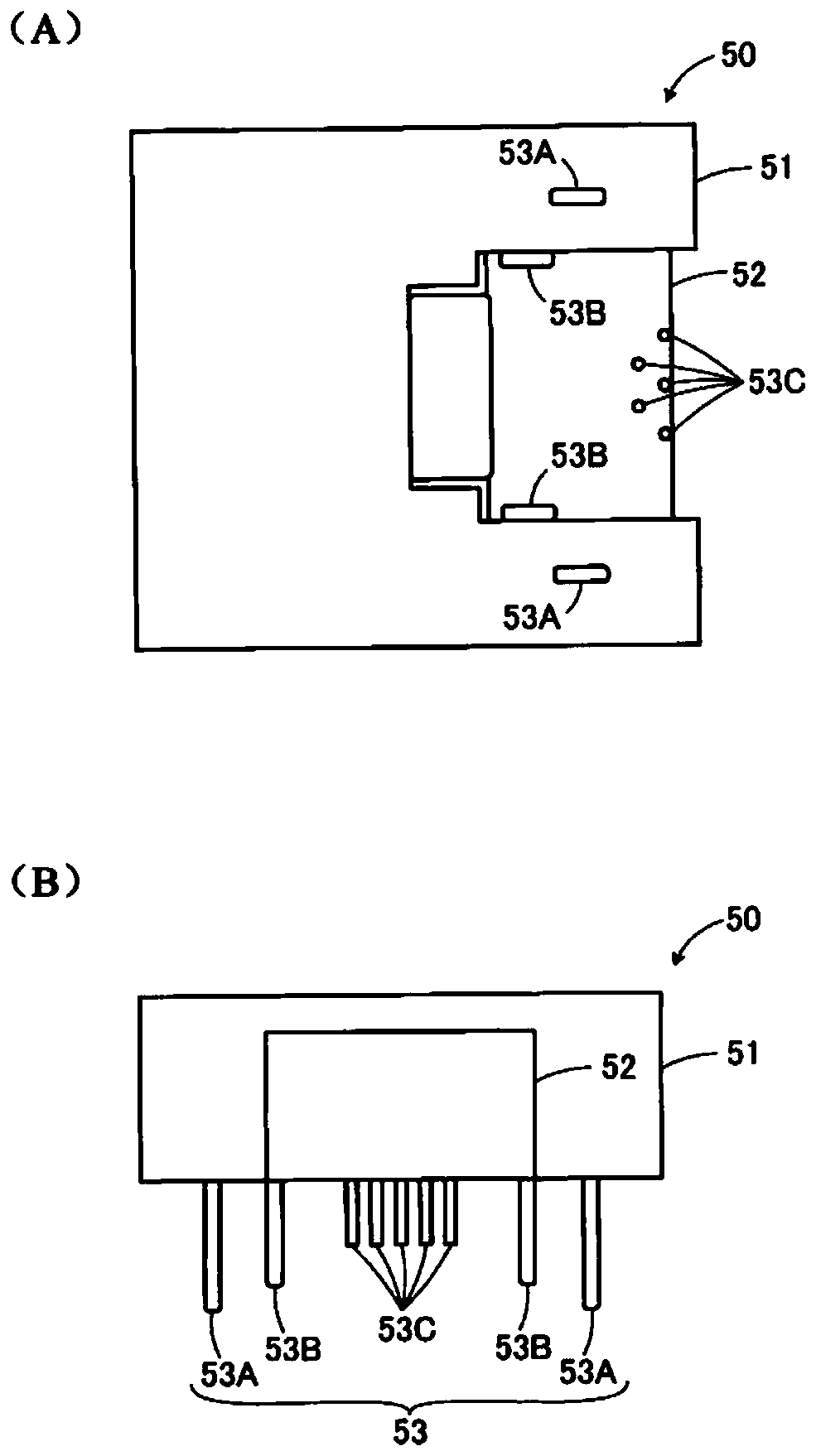

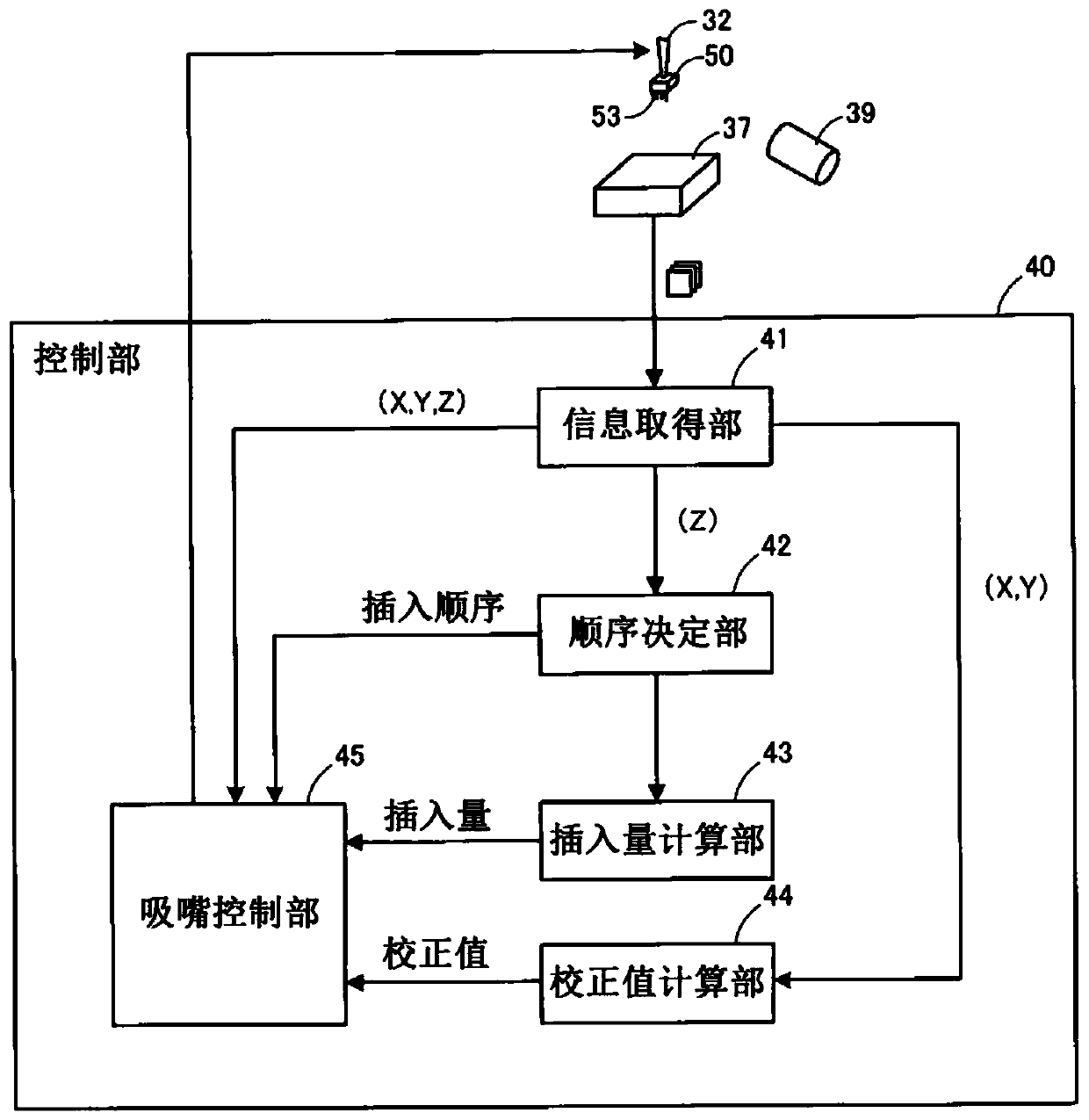

[0036] Next, a mounting device having an image processing device according to the present embodiment will be described with reference to the drawings. figure 1 It is a schematic plan view of the mounting device of this embodiment. In addition, the attachment device of this embodiment is just an example, and can be changed suitably. figure 2 It is a schematic diagram of the insertion member of this embodiment.

[0037] like figure 1 As shown, the mounting device 1 is configured to pick up the insertion component 50 from the component supply device 15 by the mounting head 30 and mount it at a predetermined position on the substrate 60 . A substrate transfer unit 11 for transferring a substrate 60 in the X-axis direction is arranged substantially at the center of the base 10 of the mounting apparatus 1 . The substrate transport unit 11 carries and positions the substrate 60 before component mounting to the lower side of the mounting head 30 from one end side in the X-axis dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com