Single cutting-edge cutting knife exclusively used for tendon sheath

A tendon sheath and blade technology, applied in the field of hand surgical scalpels, can solve the problems of accidental injury to neurovascular bundles, increased adhesion, and recurrence of tendon adhesion entrapment, etc., and achieve the effect of eliminating potential risks and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

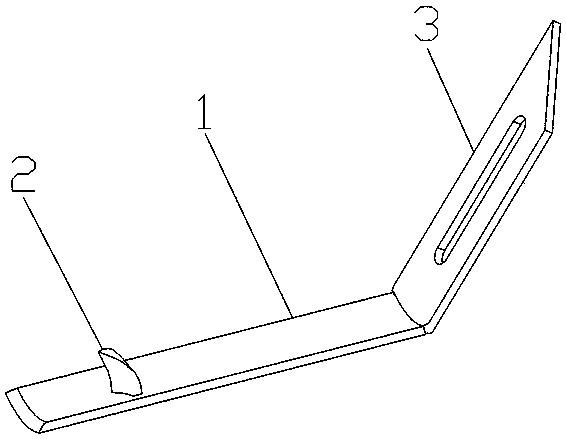

[0026] see Figure 1 to Figure 4 As shown, a knife dedicated to single-edged tendon sheath incision includes a blade 1, a blade 2 and a connecting end 3, the blade 1 is arranged on the upper end of the blade 2, the end of the blade 1 is connected to the connecting end 3, and the working end of the blade 2 faces toward the blade 1 head end;

[0027] The cross section of the blade 1 is an arc groove structure;

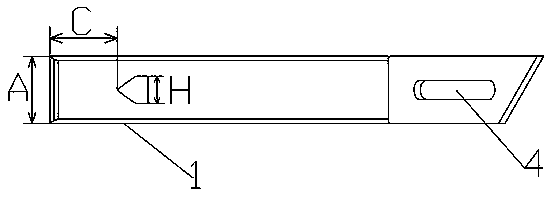

[0028] The connecting end 3 is provided with a mounting groove 4;

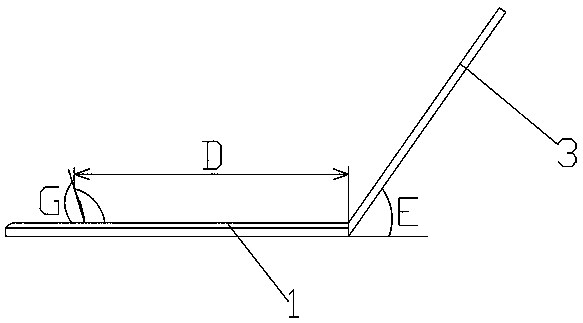

[0029] The angle E between the connecting end 3 and the horizontal plane is 50°~70°;

[0030] The width A of the blade 1 is between 4.5 mm and 5.5 mm;

[0031] The included angle B between both sides of the blade 1 and the horizontal plane is 8°~12°;

[0032] The height F of the blade 2 is 2.5 mm to 3.5 mm.

[0033] The angle G between the blade 2 and the horizontal plane is 75°-85°.

[0034] Preferably, the width A of the blade 1 is 5 mm.

[0035] Preferably, the angle E between the connecting en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com