Wire tightening device for electric wires

A wire-tightening and wire-tightening technology is applied in the field of wire-tightening devices, which can solve the problems of easy knotting of wires, reduce safety, waste resources, etc., and achieve the effects of improving convenience, reducing labor intensity, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

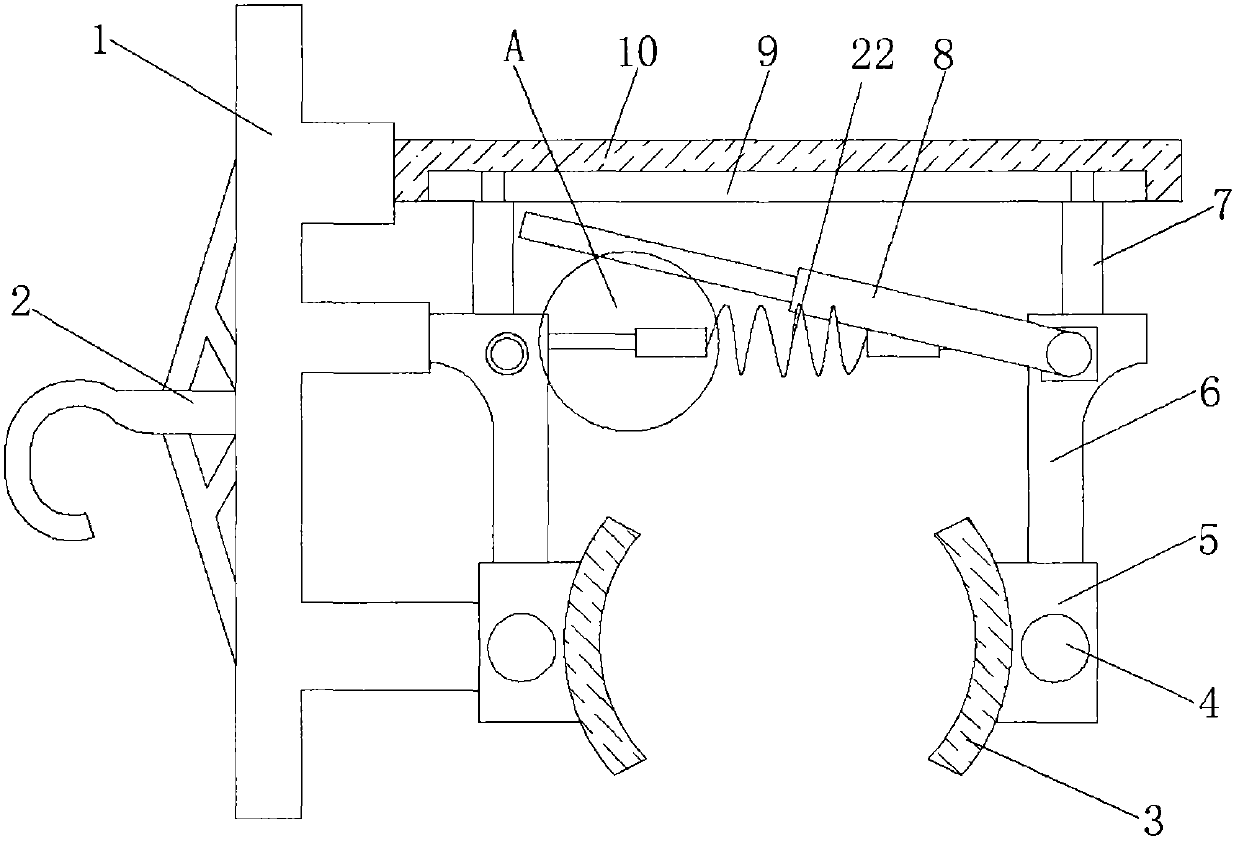

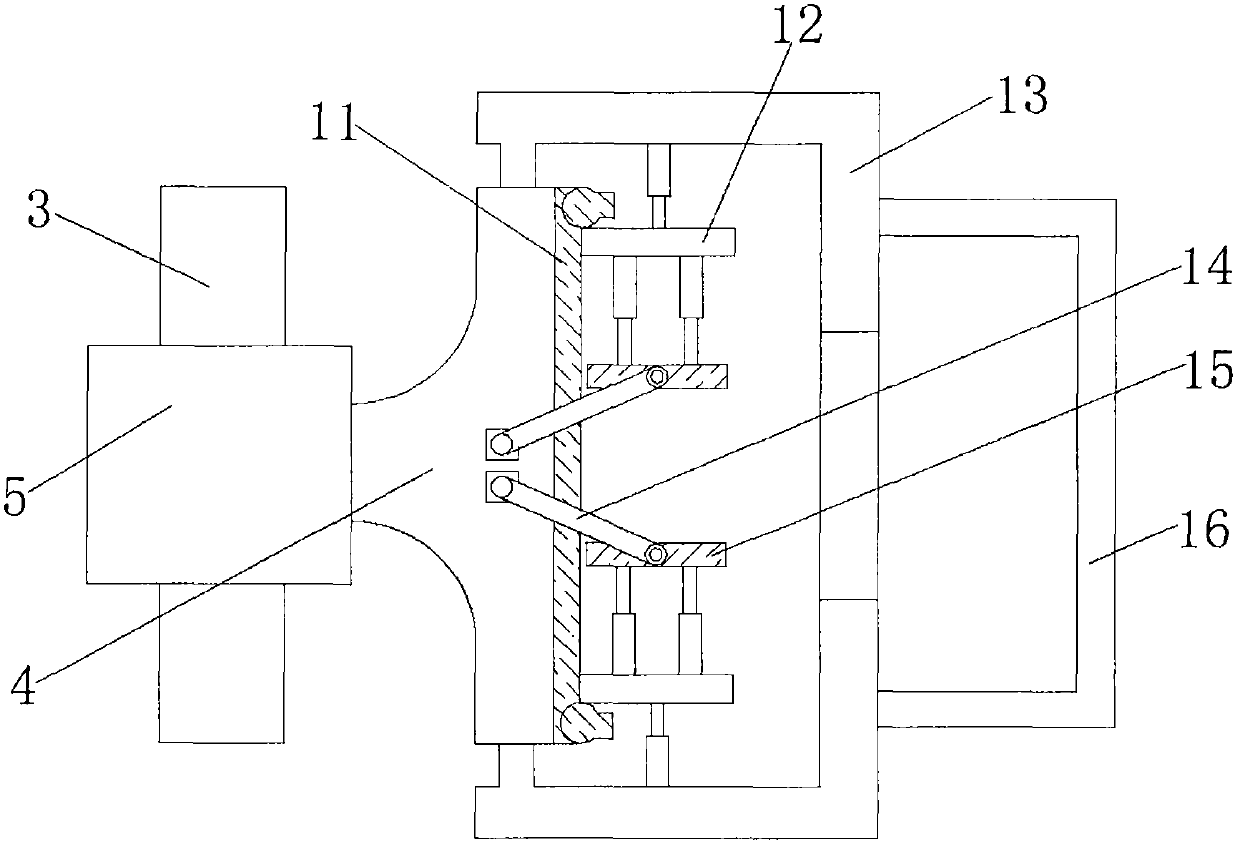

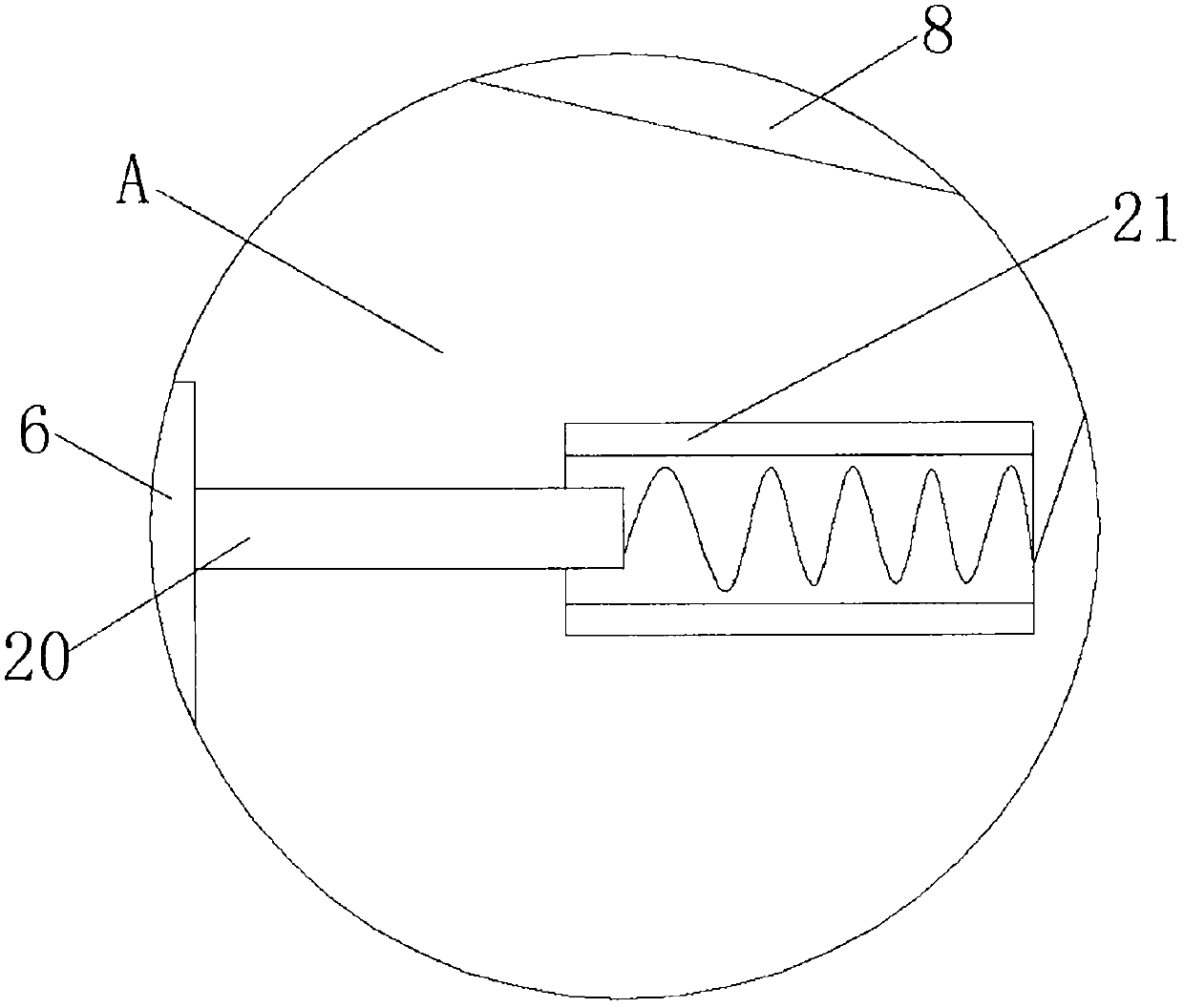

[0023] Example: refer to Figure 1-4 , a wire tightening device for electric wires. Before starting to tighten the wires, the first stop bar 8 is first removed from the locking frame 6 close to the fixed frame 1, so that the two movable blocks 20 are in the first spring 17 and the second spring 22 have elastic action at the same time, so that when the first spring 17 and the second spring 22 are stretching, the distance between the movable block 20 is pushed to increase, and then the locking frame 6 and the sliding rod 7 are linked , do a horizontal linear movement along the sliding groove 9, at the same time the distance between the two first clamping plates 3 can be increased, and then the push rod that is fixedly connected between the support frame 13 and the sliding plate 12 can be adjusted to push The rod is compressed to reduce the distance of the push rod, so that the movement of the push rod drives the sliding plate 12 to move along the slide rail 11. After the spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com