Assembled large-span wood tension string beam structure

A prefabricated, large-span technology, applied in the direction of structural elements, elongated structural components for load-bearing, building components, etc., can solve the problems of heavy weight, high cost, and high rigidity of the engineering foundation, and achieve light weight, The effect of widening the use span and high lateral stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

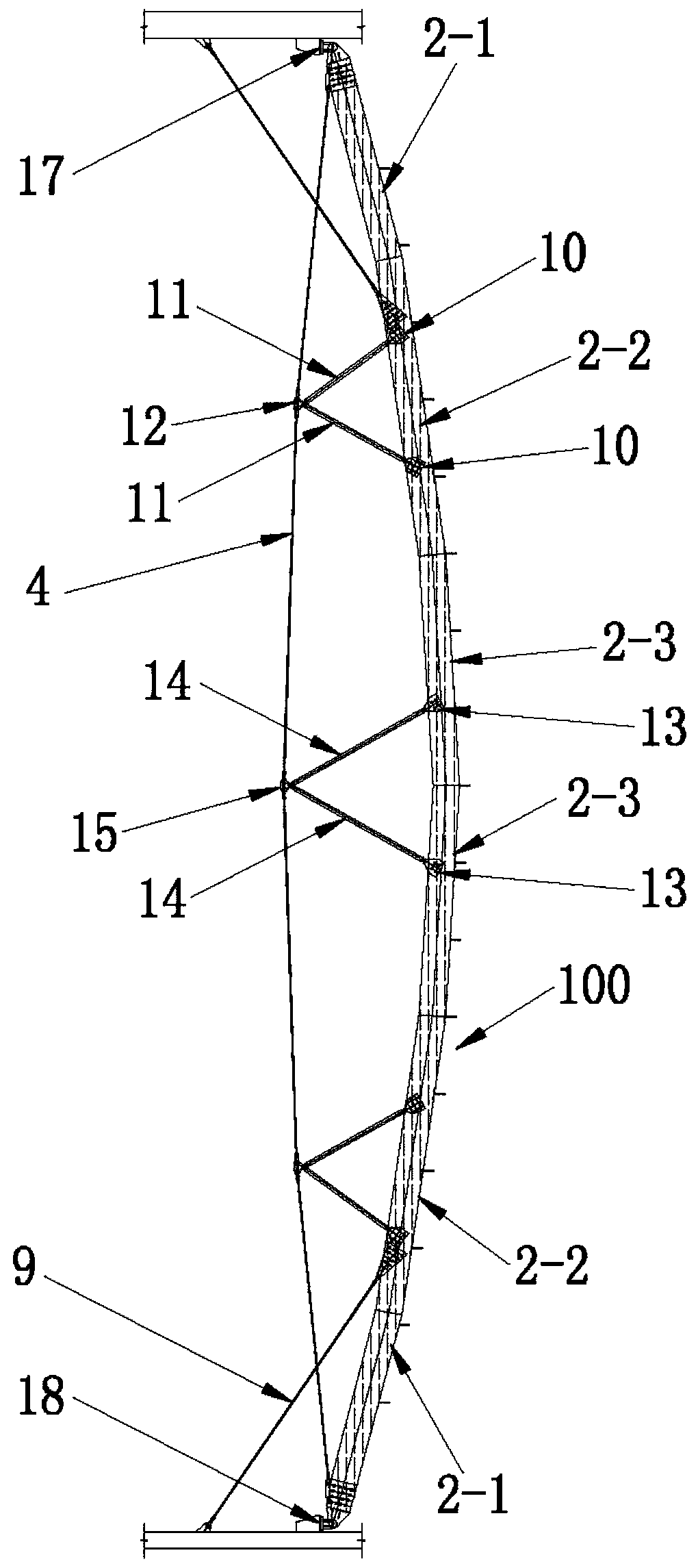

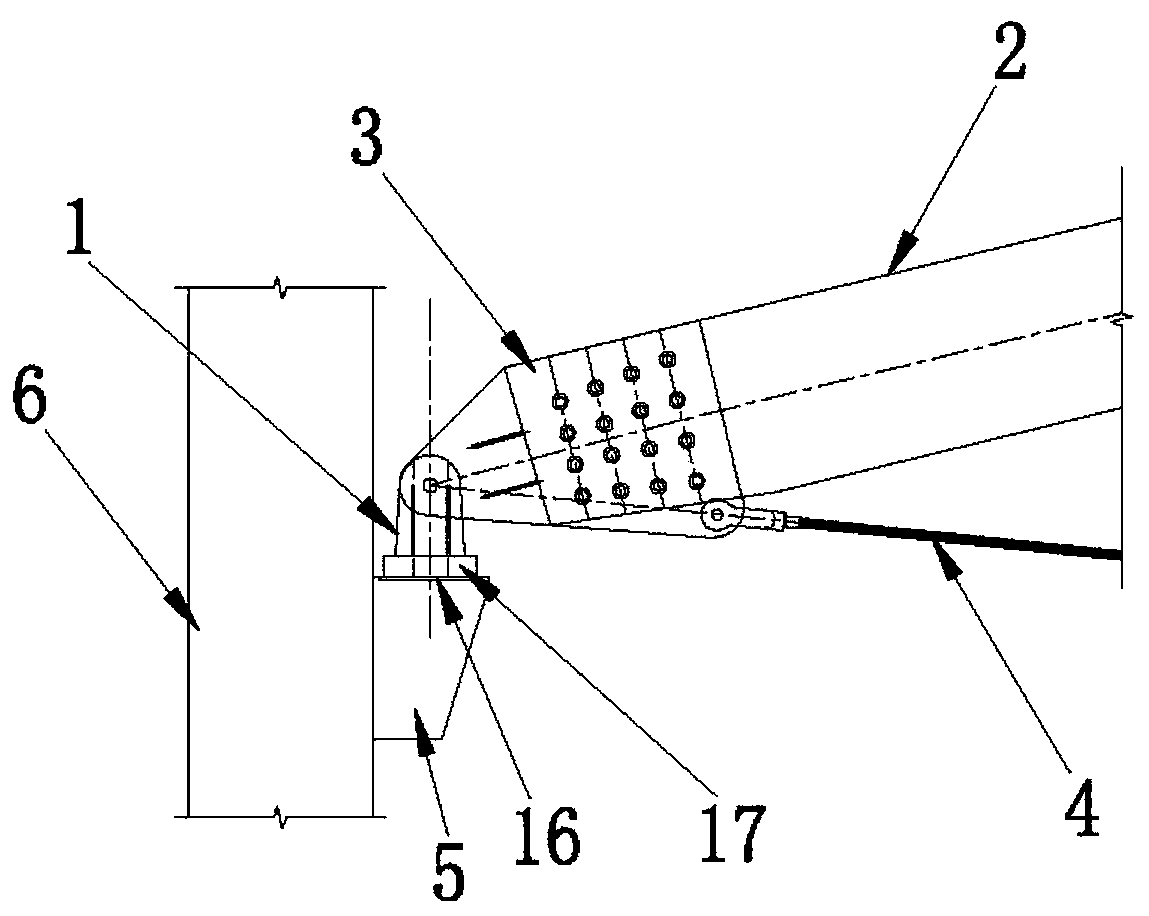

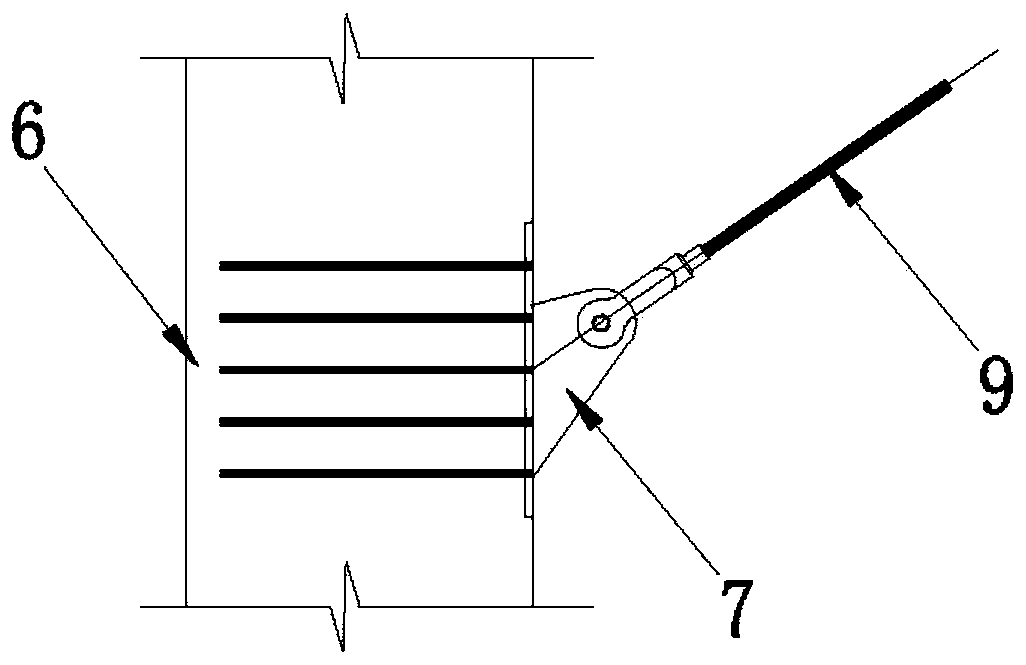

[0027] Example: such as figure 1 As shown, a prefabricated long-span wooden string beam structure includes several fabricated glulam string beam groups 100 and support seats 1 arranged at the bottoms of both ends of the fabricated glulam string beam group 100; the fabricated glulam string beam group 100 It is formed by connecting multiple string string beam sections 2 of the same combination, and the adjacent string string beam segments 2 are connected through metal connectors and wooden components by fastening with bolts.

[0028] Specifically, the outer side of the adjacent string beam section 2 is connected with a metal connector, and the metal connector can be a connecting plate, and the metal connector and the wood member (string beam section 2) are fastened by bolts to connect the adjacent string beam section 2; thus Realize assembly design and construction; the string string beam structure has the characteristics of segmental production, assembly construction, light wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com