Cleaning device used for polishing mechanical gears after processing

A technology for cleaning devices and gears, applied in liquid cleaning methods, cleaning methods and utensils, filtration and separation, etc. It can solve the inconvenience of batch loading and unloading of bearings, the inability to slide and remove the cleaning box freely, and the unreasonable installation position of supports, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

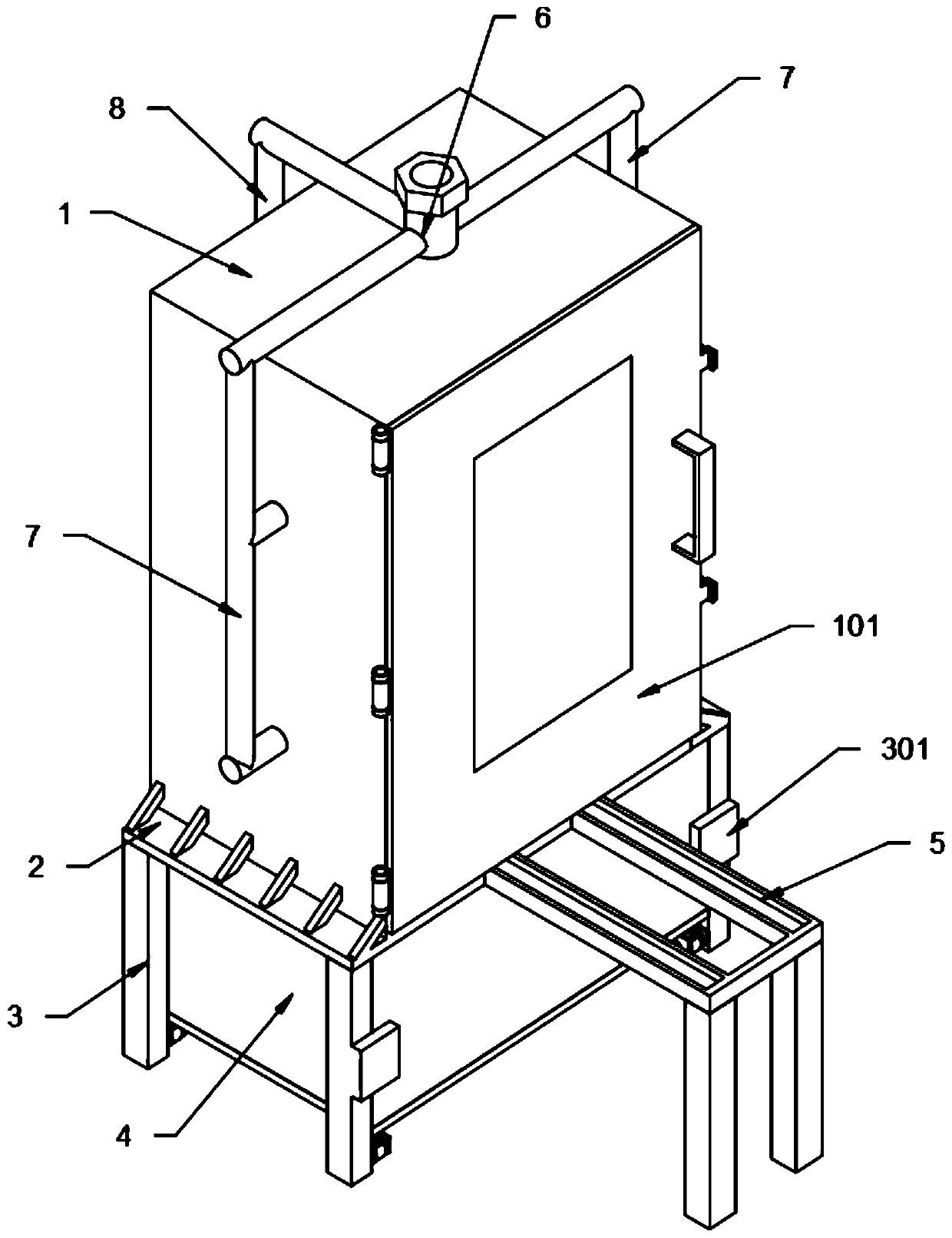

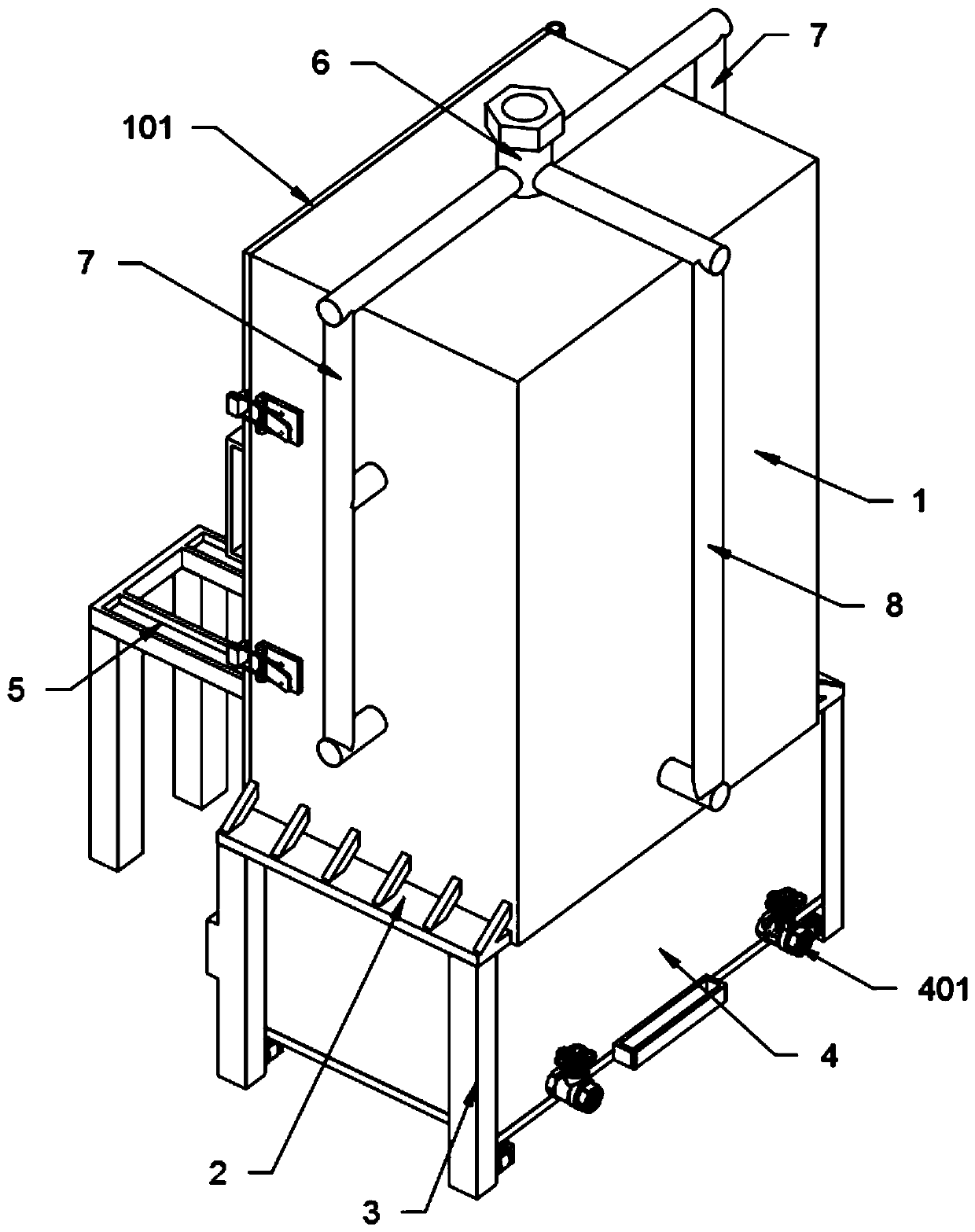

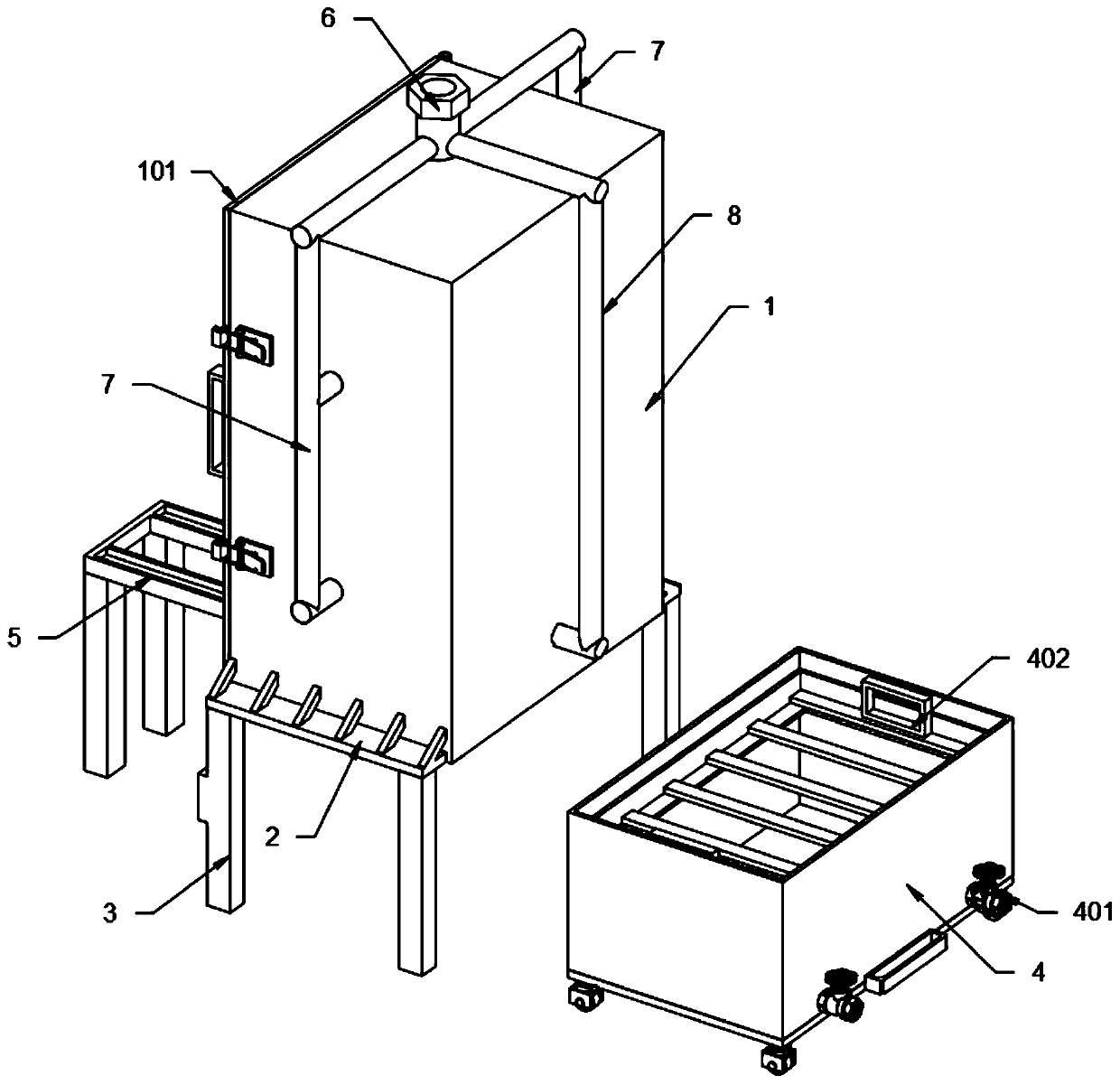

[0038] as attached figure 1 to attach Figure 9 Shown:

[0039] The present invention provides a cleaning device for machining and grinding of mechanical gears, comprising a cleaning box 1, Box door 101 , floor frame 2, support leg 3, backing plate 301, water tank trolley 4, water discharge ball valve 401, filter screen 402, track 5, thickened water inlet pipe 6, water guide side pipe 7, back water guide pipe 8, side water spray Pipe 9, connected to water guide pipe 10, middle water spray pipe 11, gear 12, gear hanger 13, bottom support frame 131, support positioning rod 132, hanging rod 133, bending positioning plate 134, track groove 14 and water spray frame 15 The cleaning box 1 is arranged as a vertical cuboid as a whole, and a box door 101 is pivotally hinged on the front opening, and the box door 101 is tightened by two pressing locks symmetrically welded to the front end of the right side wall of the cleaning box 1. Closed positioning; the cleaning box 1 is welded a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com