Hot extrusion divergent die capable of preventing temperature difference bonding damage

A hot extrusion and destruction technology, applied in the direction of metal extrusion dies, etc., can solve problems such as sticky agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

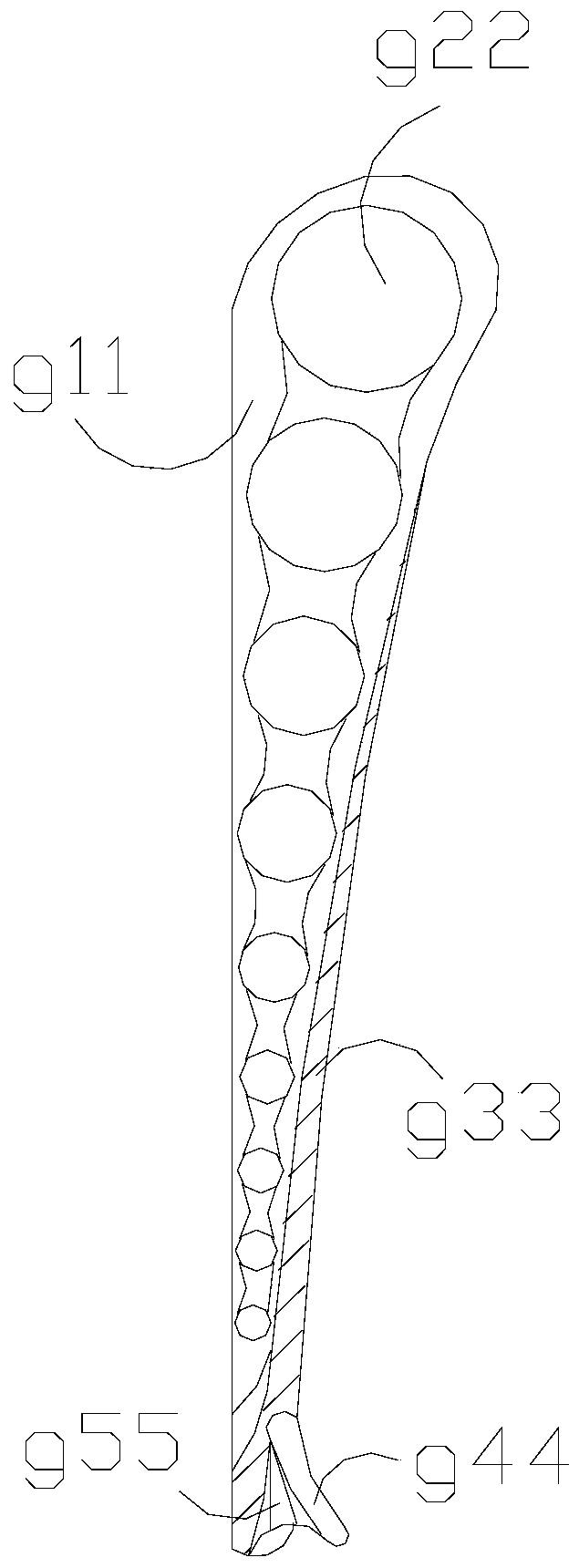

[0028] as attached figure 1 to attach Figure 7 Shown:

[0029] The present invention provides a heat-extrusion shunting die of the type of anti-bonding and destroying due to temperature difference.

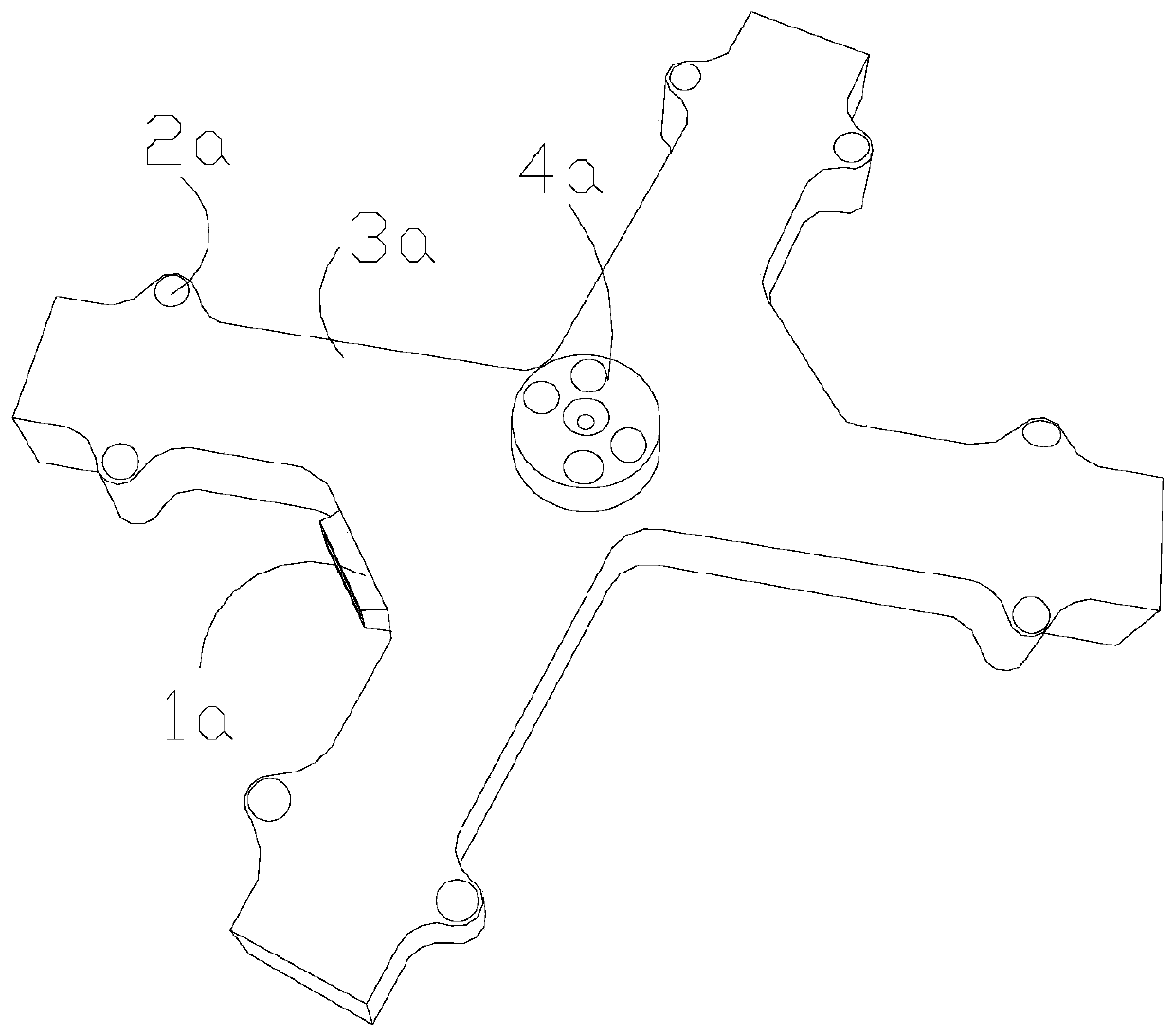

[0030] The split smoothing opening 1a is welded to the outer surface of the upper mold 3a and penetrates each other, the alignment opening 2a penetrates the inside of the upper mold 3a, and the outer surface of the upper mold 3a is equipped with a middle fixed block 4a.

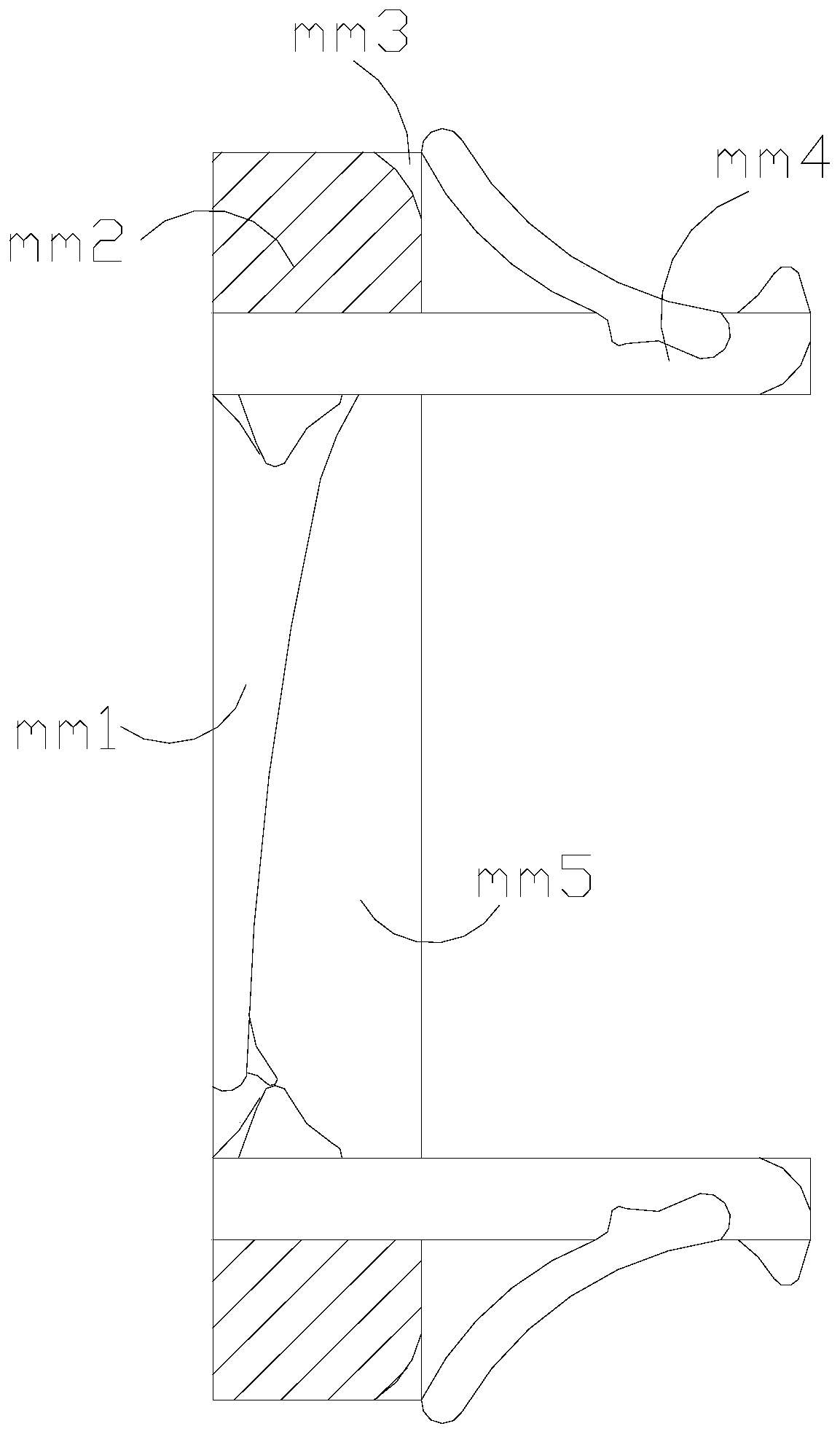

[0031] The diversion smoothing port 1a includes an appropriate amount of sealing rod mm1, a gap layer mm2, a curved angle protection mm3, an auxiliary ejector rod mm4, and a connecting port mm5, the appropriate amount of sealing rod mm1 is connected with the auxiliary ejector rod mm4, and the auxiliary ejector rod The rod mm4 runs through the inside of the gap layer mm2, the outer surface of the gap layer mm2 is pasted with a curved angle protector mm3, the appropriate amount of sealing rod mm1 is located insi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap