Anti-rotation vacuum sucker device

A vacuum suction cup and anti-rotation technology, which is applied in the direction of transportation and packaging, manipulators, chucks, etc., can solve problems such as the self-rotation of the vacuum suction cup, affecting the normal operation of the vacuum suction cup, and the failure of the suction operation of the vacuum suction cup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

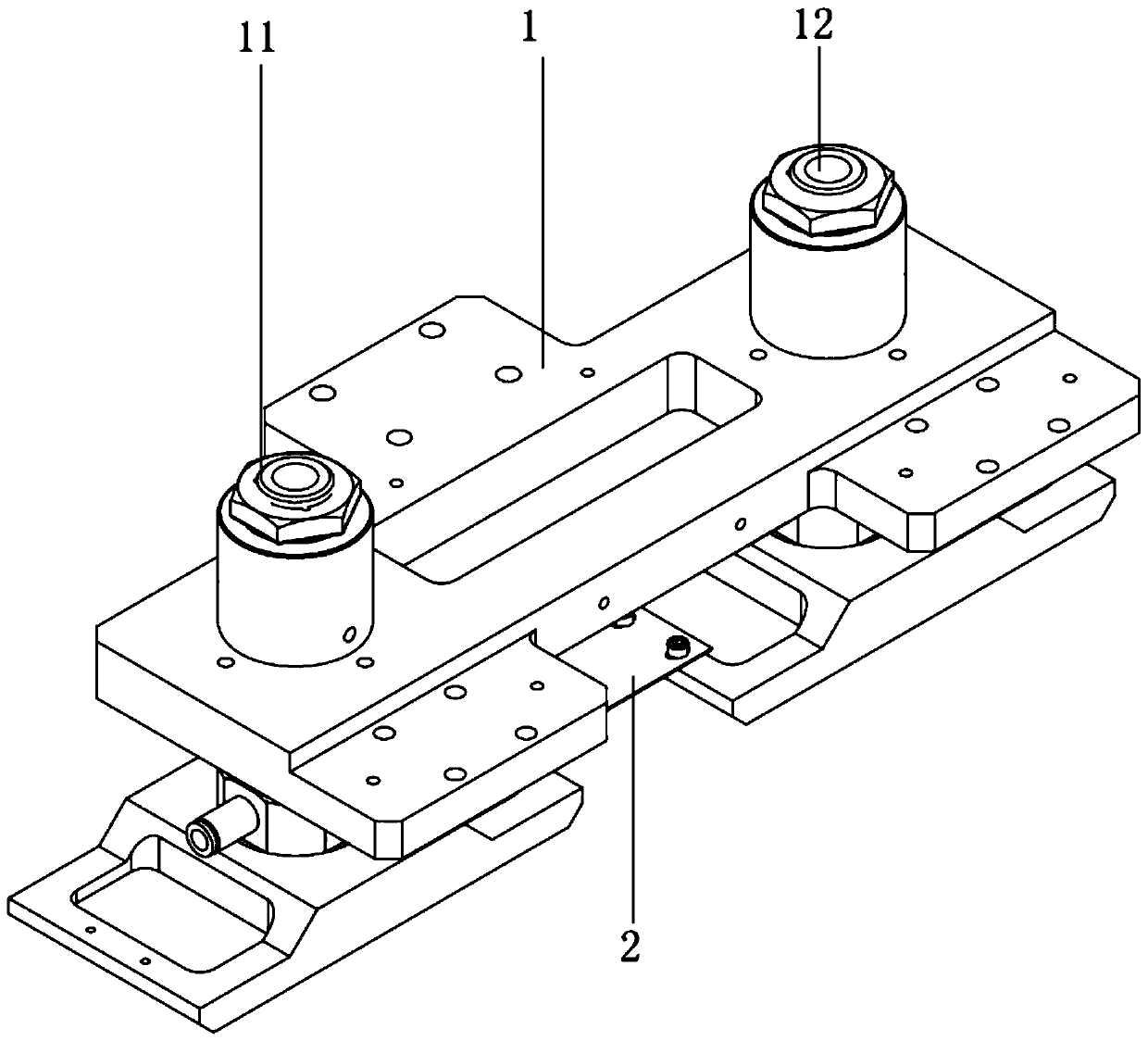

[0027] see Figure 1 to Figure 3 , the figure shows an anti-rotation vacuum chuck device provided by an embodiment of the present invention, including:

[0028] Install substrate 1;

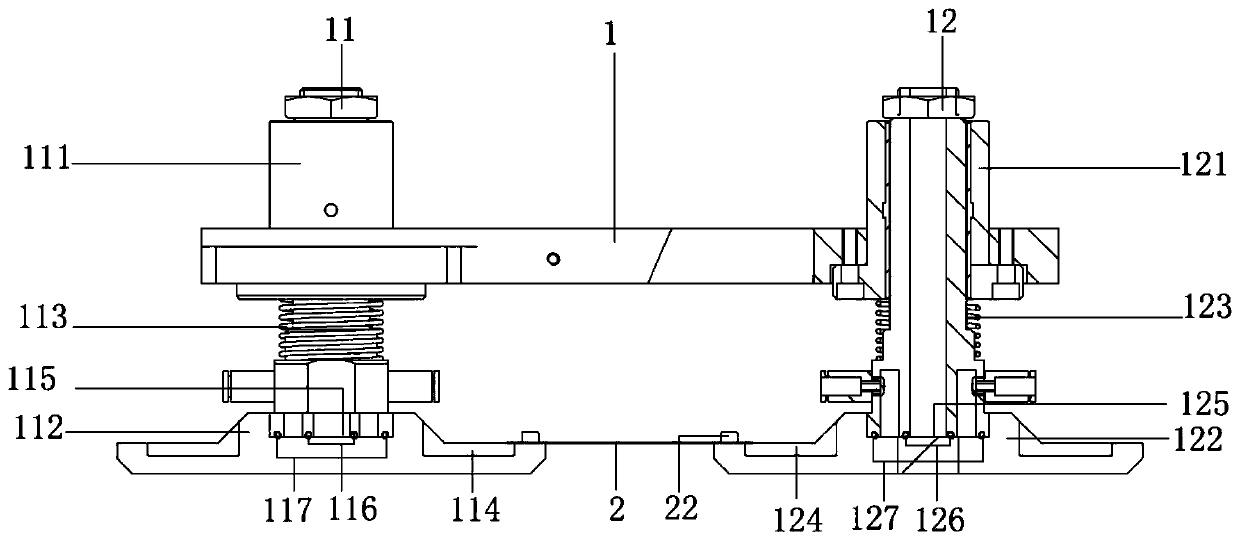

[0029] The first sucker component 11 includes a first connecting rod 111 and a first sucking cup 112, the first sucking cup 112 is fixedly connected to the bottom of the first connecting rod 111, the first connecting rod 111 is passed through the installation substrate 1, and the first A first spring 113 is sleeved on the connecting rod 111, and the first spring 113 is located between the mounting substrate 1 and the first suction cup 112;

[0030] The second sucker component 12 includes a second connecting rod 121 and a second sucking cup 122, the second sucking cup 122 is fixedly connected to the bottom of the second connecting rod 121, the second connecting rod 121 is passed through the installation substrate 1, and the second A second spring 123 is sleeved on the connecting rod 121, and the...

Embodiment 2

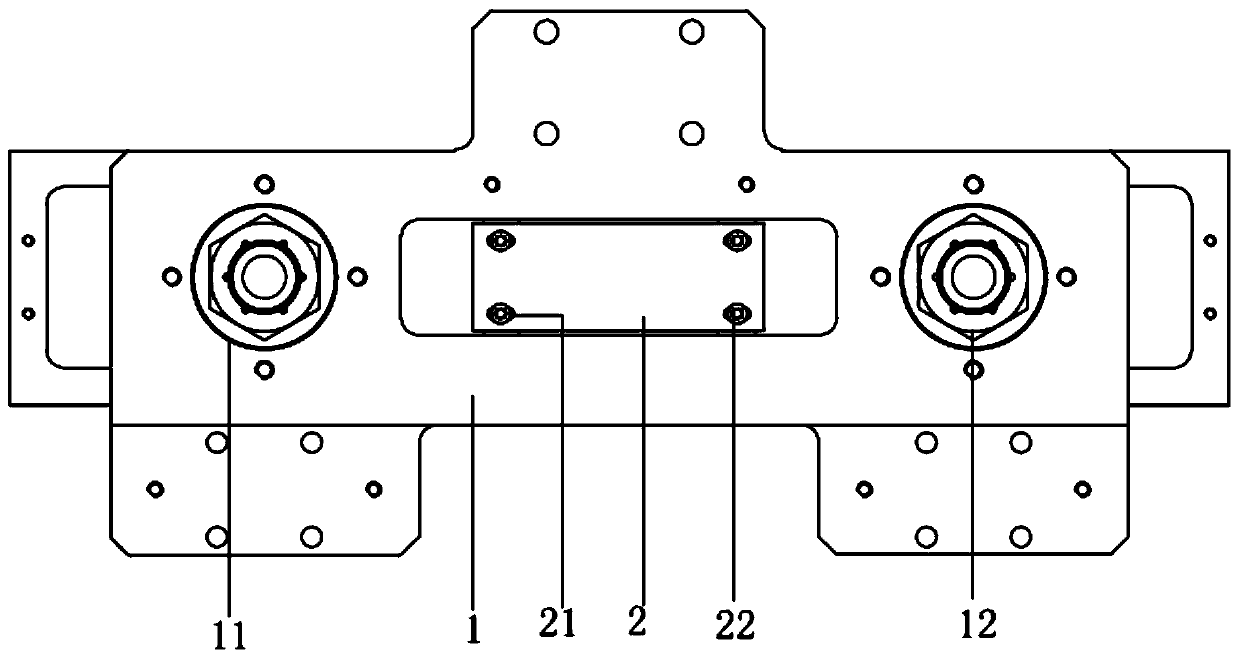

[0040] see Figure 1 to Figure 3 , the figure shows an anti-rotation vacuum chuck device provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solution as an improvement: the connecting shrapnel 2 is rectangular shrapnel.

[0041] Since both the first suction cup and the second suction cup are square suction cups, the two ends of the rectangular shrapnel better match the edges of the suction cups, thereby achieving a better limiting effect.

Embodiment 3

[0043] see Figure 1 to Figure 3 , the figure shows a anti-rotation vacuum chuck device provided by the third embodiment of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the first connecting rod 111 The bottom of the first suction cup 112 is snapped into the preset first slot 115 on the top of the first suction cup 112, and a concentrically arranged first inner seal is installed between the bottom surface of the first connecting rod 111 and the bottom of the first slot 115. Ring 116 and the first outer sealing ring 117. The bottom of the second connecting rod 121 is snapped into the preset second slot 125 on the top of the second suction cup 122, and a concentric arrangement is installed between the bottom surface of the second connecting rod 121 and the bottom of the second slot 125. The second inner sealing ring 126 and the second outer sealing ring 127.

[0044] There are two l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com