Self-bearing plate type reinforcement mesh frame

A steel grid frame and panel type technology, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of deformation and damage of steel grid structure, uneven pressure distribution, poor pressure bearing capacity, etc. Stress capacity, convenient construction, strong pressure bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

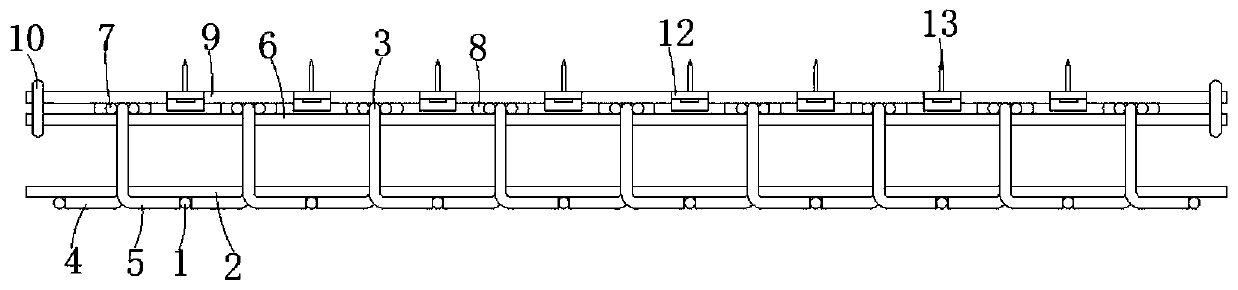

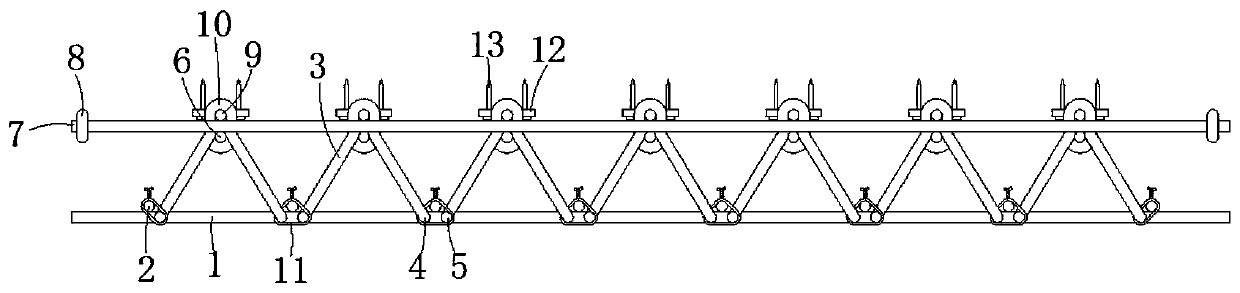

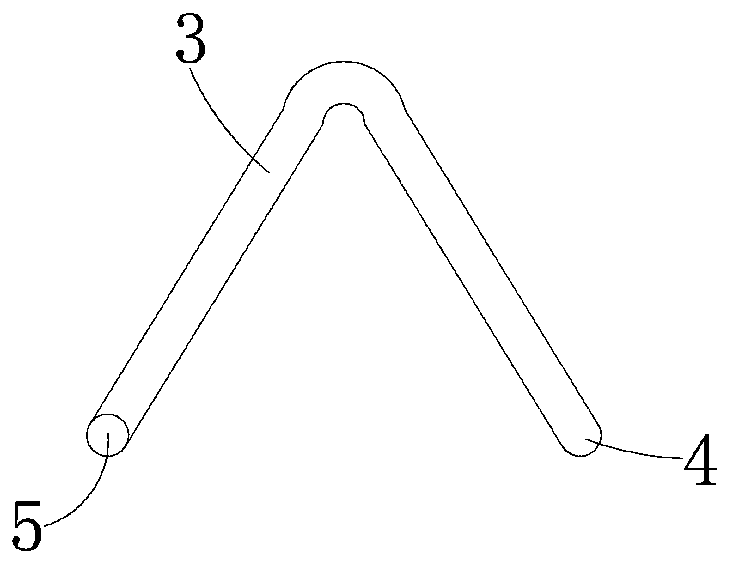

[0027] Such as Figure 1-5 Shown: a self-supporting slab-type steel grid frame, including the bottom frame structure, support structure and top frame structure, the bottom frame structure and the support structure are bound together by a plurality of fastening steel wires 11, the support structure and the top frame structure The bottom frame structure includes a plurality of bottom horizontal distribution ribs 1 and bottom bottom longitudinal distribution ribs 2 arranged at equal intervals, each bottom horizontal distribution rib 1 and bottom bottom longitudinal distribution rib 2 are welded at a vertical angle Together, the distance between every two adjacent bottom-layer transverse distribution ribs 1 is consistent with the distance between every two adjacent bottom-layer lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com