Method for assembling high and low temperature vacuum stepping motor

A low-temperature vacuum, stepper motor technology, used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as uneven pressure on magnetic steel, damage to stator or motor housing, and excessive coaxiality. , to achieve the effect of ensuring accuracy and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

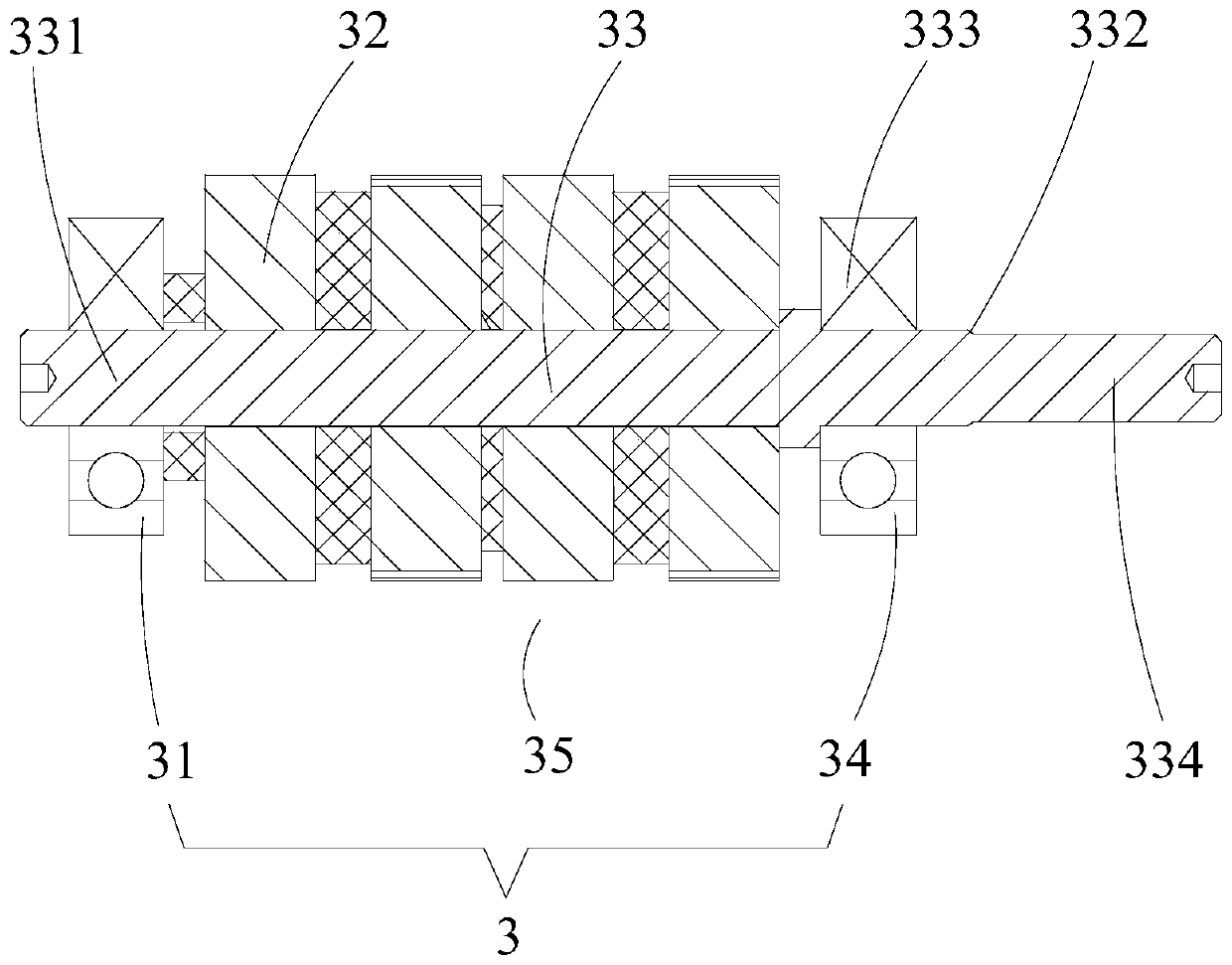

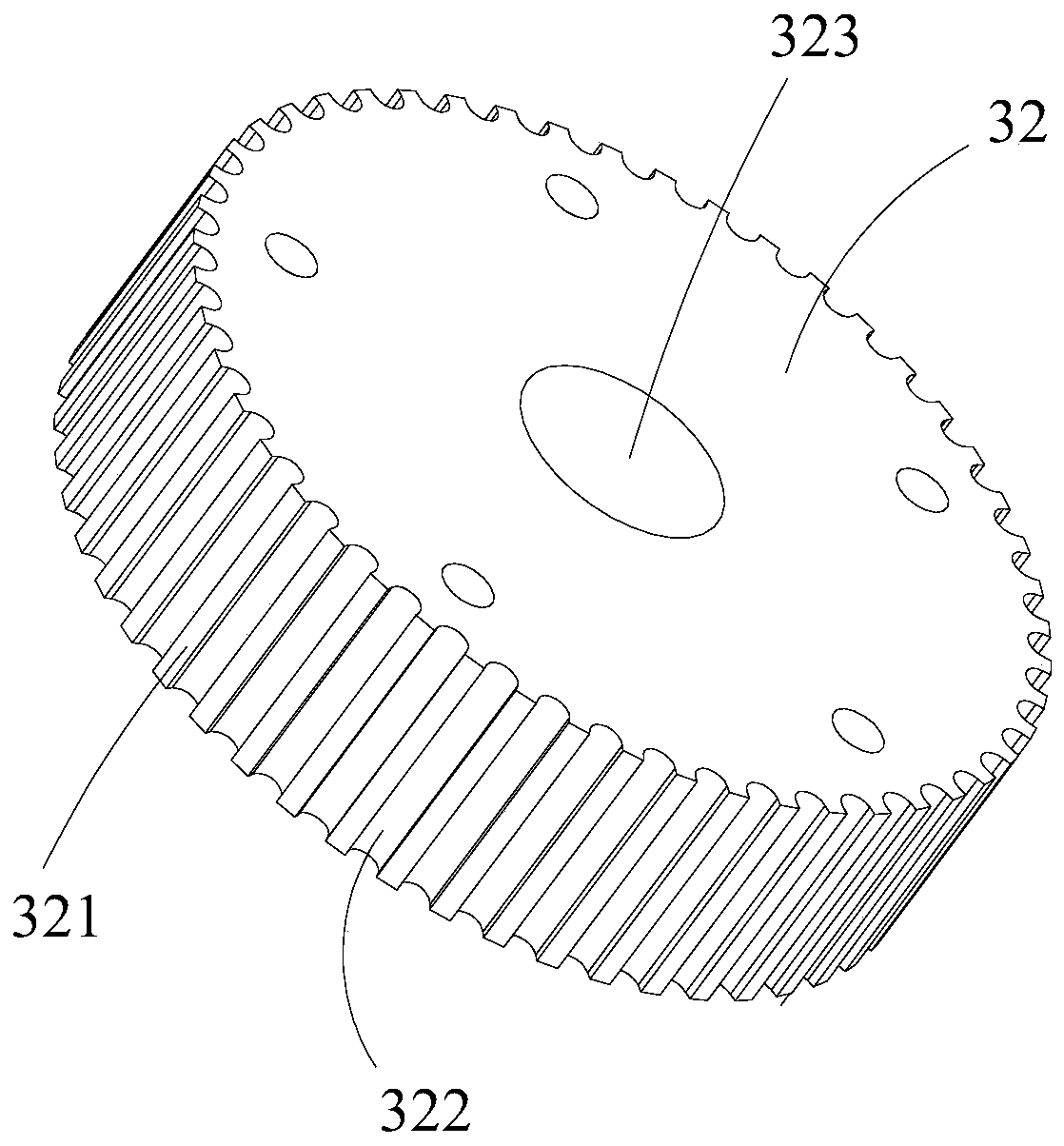

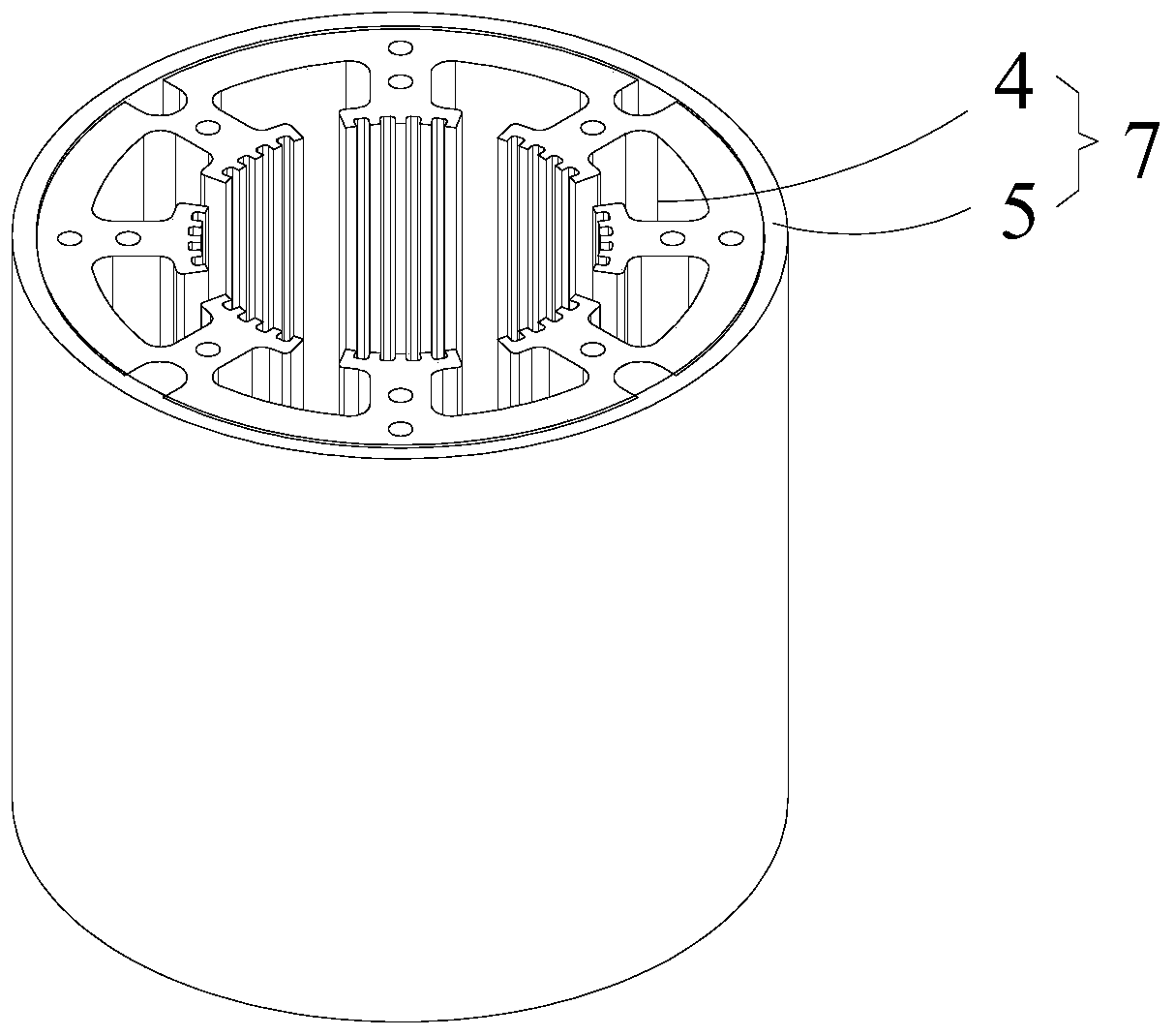

[0082] Such as Figure 1-8 As shown, a method for assembling a high and low temperature vacuum stepping motor includes the following steps:

[0083] Step 1, install the rotating shaft 33 on the first tooling 12, the first tooling 12 is installed on the moving plate 114, install the iron core 32 on the second tooling 13, and the second tooling 13 is installed on the support 11 Above, the electric cylinder 2 is connected to the moving plate 114, and the electric cylinder 2 is arranged vertically. The moving plate 114 slides and fits with the support 11 along the axial direction of the electric cylinder 2. The rotating shaft 33, The iron core 32 and the electric cylinder 2 are arranged coaxially, and the electric cylinder 2 drives the moving plate 114 to slide relative to the support 11 to complete the assembly of the rotating shaft 33 and the iron core 32 to form a rotor Iron core assembly 35;

[0084] Step 2, remove the second tooling 13, and remove the rotor core assembly 35...

Embodiment 2

[0091] Such as Figure 1-8 As shown, a method for assembling a high and low temperature vacuum stepping motor as described in Embodiment 1, the electric cylinder 2 is connected with a control system 6, and the control system 6 is used to control the action of the electric cylinder 2 , the control system 6 is electrically connected to the electric cylinder 2, the control system 6 includes a control module 61 and an HMI module 62, wherein,

[0092] The HMI module 62 is used to provide an interactive interface between the control system 6 and the user, including receiving user instructions, transmitting the user-input instructions to the control module 61, and displaying the electric cylinder 2 displacement results;

[0093] The control module 61 controls the electric cylinder 2 to drive the moving plate 114 to a predetermined position according to the instruction, and the control module 61 is electrically connected with the electric cylinder 2 and the HMI module 62 respectively...

Embodiment 3

[0100] Such as Figure 1-8 As shown, a method for assembling a high and low temperature vacuum stepping motor as described in Embodiment 1 or 2, the support 11 includes an upper seat plate 111 and a lower seat plate 112, and the upper seat plate 111 and the lower seat plate 112 A sliding rod 113 is connected between the seat plates 112, and the moving plate 114 slides and fits with the sliding rod 113 along the axial direction of the electric cylinder. The electric cylinder 2 includes a cylinder barrel 21 and a movable rod 22. The upper seat plate 111 is connected with the cylinder 21 , and the moving plate 114 is connected with the movable rod 22 .

[0101] On the basis of the above, in a further preferred manner, there are four sliding rods 113, all the sliding rods 113 are distributed on the same circumference on the lower seat plate 112, and all the sliding rods 113 are parallel to each other.

[0102] Four sliding rods 113 are distributed on the circumference, and all th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com