An electromagnetic lock working power reduction circuit

A technology of working power and electromagnetic lock, which is applied to circuits, electromagnets, electromagnets with armatures, etc., can solve the problems of reducing maintenance power and high temperature of electromagnetic locks, and achieves the advantages of reducing working temperature, increasing cost and simple circuit design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

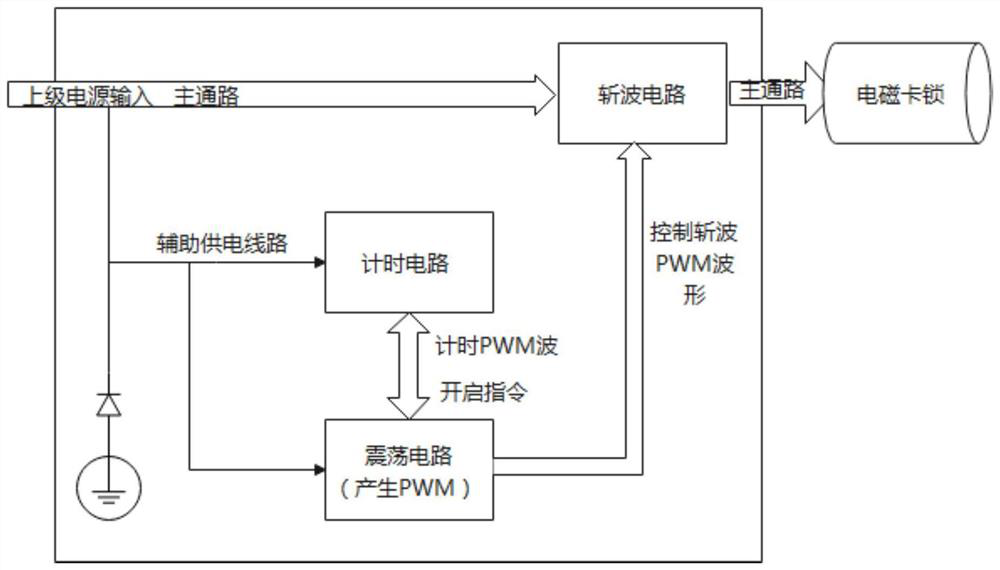

[0017] The invention provides an electromagnetic lock working power reduction circuit, such as figure 1 As shown, it includes an oscillator circuit, a timing circuit and a chopper circuit; the bus power supply is connected to the chopper circuit, and the chopper circuit is connected to the electromagnetic lock. Circuit and timing circuit, the oscillator circuit generates two PWM waves successively, the first PWM wave is sent to the timing circuit, and the timing circuit starts timing; after the timing reaches the set time, the timing circuit sends the second PWM wave to the oscillator circuit to start command; the oscillation circuit sends the second PWM wave to the chopper circuit, so that the DC power supply waveform output before the chopper circuit becomes a PWM waveform; the current at the input terminal of the electromagnetic lock forms a pulse sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com