Oil control type oiling device for chemical fiber processing

A technology of chemical fiber and chemical fiber yarn, which is applied in fiber processing, filament/thread forming, textile and paper making, etc. It can solve the problems of chemical fiber processing influence, polluting workbench, not very good, etc., to avoid pollution, save cost, and improve Effects of oil quality avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

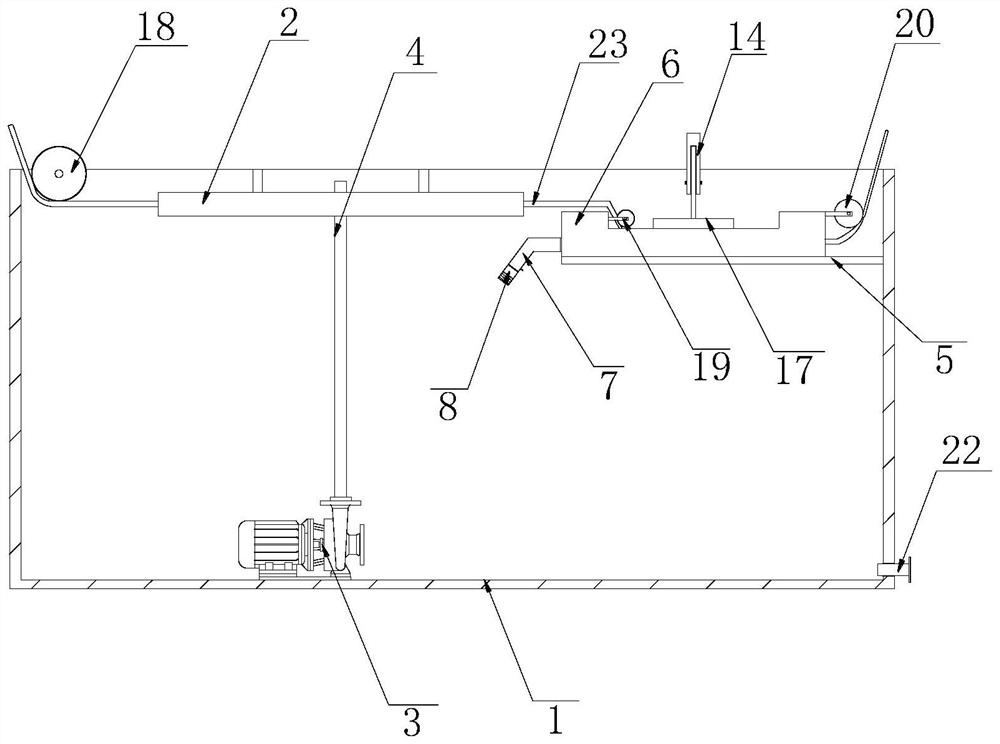

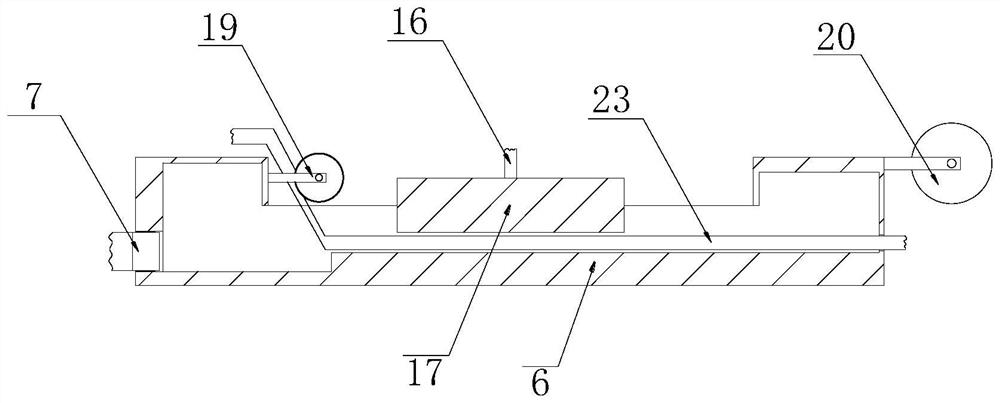

[0028] Such as figure 1 As shown, the present invention discloses an oil-controlling oiling device for chemical fiber processing, which includes an oil tank 1 and an oiling mechanism 2. The oiling mechanism 2 is used to spray the oil in the oil tank 1 on the chemical fiber filaments 23. An oil control plate 6 is arranged in the fuel tank 1, and the oil control plate 6 can be fixed on the side wall of the fuel tank 1 through the support plate 5, or directly or indirectly fixed in the fuel tank 1 by other forms. A pressure plate 17 is arranged above the oil control plate 6. There is a gap between the oil control plate 6 and the pressure plate 17. The chemical fiber filament 23 output by the oiling mechanism 2 passes through the gap between the pressure plate 17 and the oil control plate 6. The pressure plate 17 And the oil control plate 6 generates pressure on the passing chemical fiber 23 for oil control inside the chemical fiber 23 .

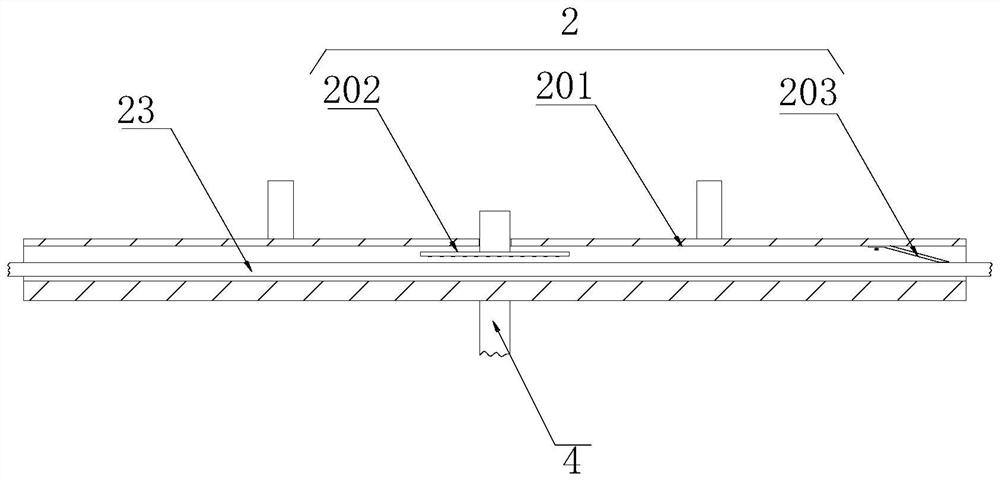

[0029] The oiling mechanism 2 is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com