Inorganic explosion-proof bridge bracket

A bridge and inorganic technology, applied in the field of inorganic explosion-proof bridge supports, can solve the problems of insignificant effect, waste of manpower and material resources, etc., to achieve strong structural ductility and elastic absorption capacity, prolong service life, good heat insulation and corrosion resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

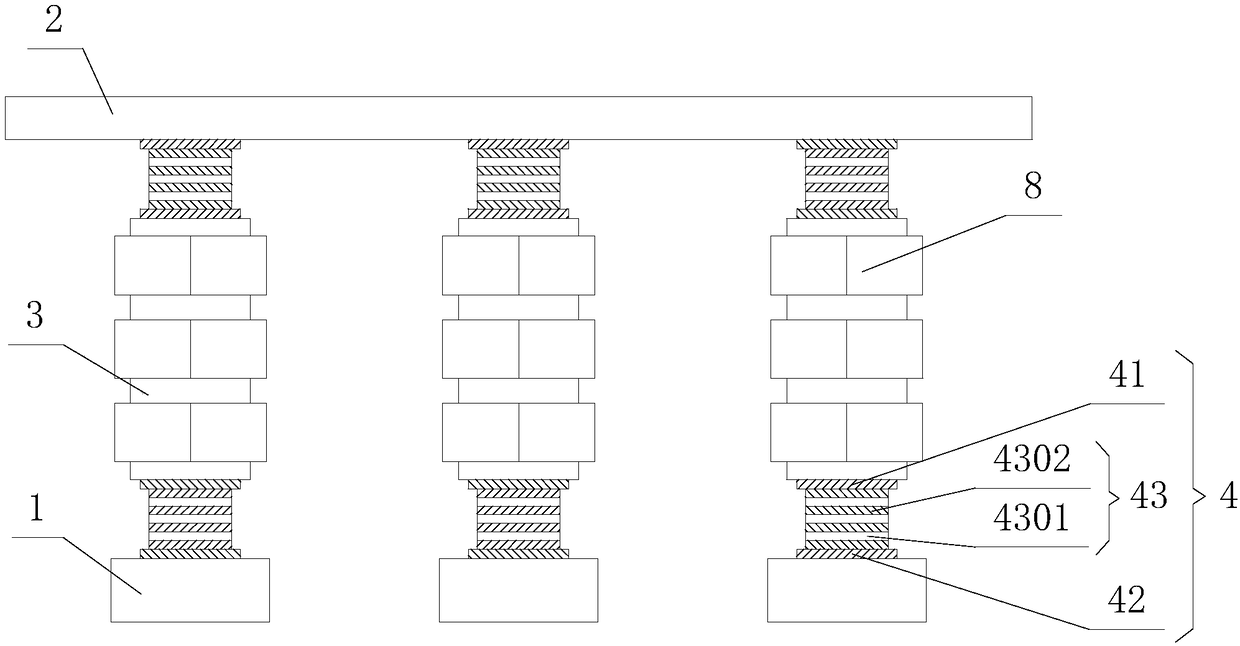

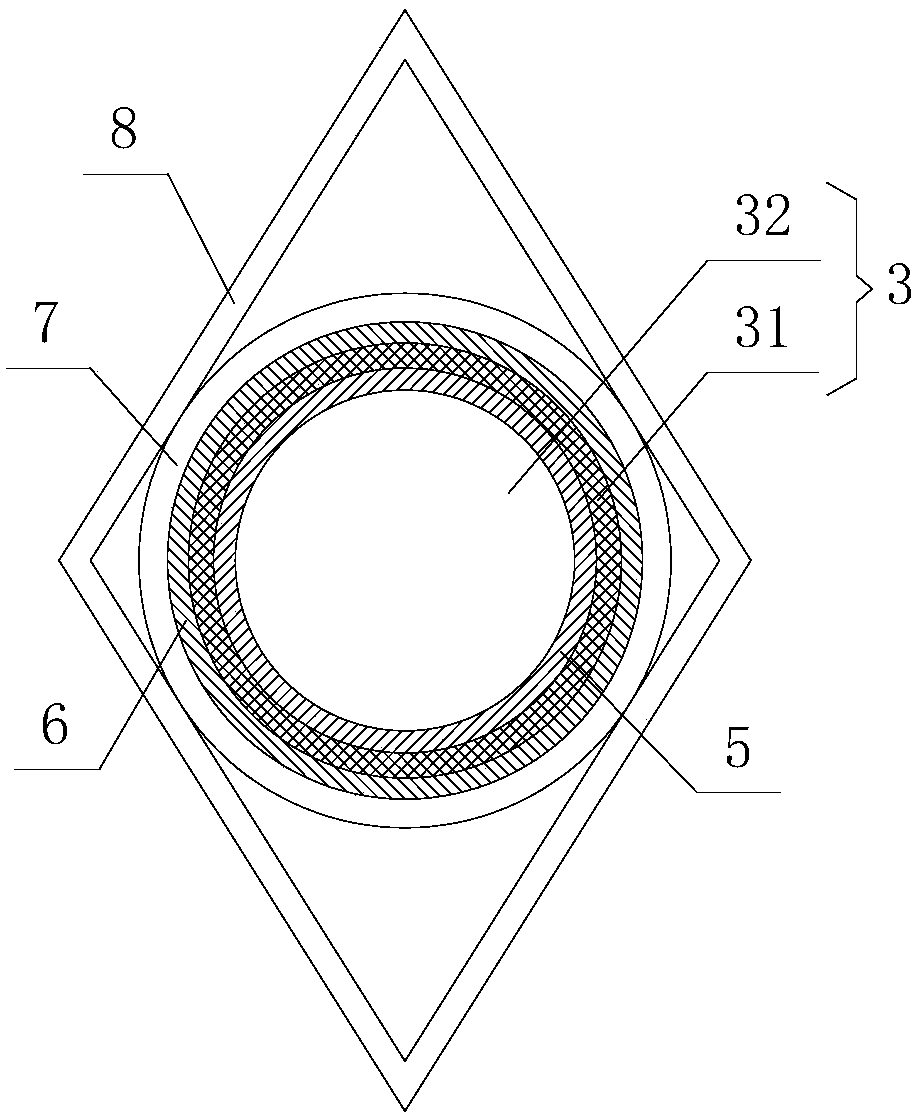

[0017] Such as figure 1 and figure 2 As shown, the inorganic explosion-proof bridge support provided in this embodiment includes a bridge pier 1, a bridge body 2 and a bridge pillar 3, and a composite connecting seat 4 is provided between the bridge pillar 3, the bridge pier 1 and the bridge body 2, and the composite connecting seat 4 It includes an upper sealing plate 41, a lower sealing plate 42 and a rubber bearing 43. The rubber bearing 43 is located between the upper sealing plate 41 and the lower sealing plate 42, and is bonded to the upper sealing plate 41 and the lower sealing plate 42. The rubber support 43 includes several layers of rubber protection layers 4301 and several layers of steel plate layers 4302, and several layers of rubber protection layers 4301 and several layers of steel plate layers 4302 are alternately overlapped, wherein the bottommost and topmost layers are both steel plate layers 4302, and the bridge pillars 3 and the bridge pier 1, the bottom ...

Embodiment 2

[0019] This embodiment is basically the same as Embodiment 1, except that the bridge pillar 3 is changed, and several fluorescent warning strips are uniformly arranged on the surface of the inorganic layer 6 of the bridge pillar 3 .

Embodiment 3

[0021] This embodiment is basically the same as Embodiment 1, except that the diversion housing 8 is changed, and an auxiliary reinforcing rib perpendicular to the inner wall of the diversion housing 8 is also provided between the inner wall of the diversion housing 8 and the outer wall of the bridge pillar 3, and The surface of the shunt casing 8 is coated with a corrosion-resistant layer.

[0022] The rubber support 43 in the composite connection seat 4 of the present invention is composed of several layers of rubber protection layers 4301 and several layers of steel plate layers 4302 alternately overlapping, which can increase the reliability of the rubber support 43. When the bridge vibrates, the composite connection seat 4 It can absorb vibration, so as to prevent the bridge pier 1 from being damaged by vibration; the included angle of the water flow or the wind impact direction of the diversion shell 8 can divert the water flow or wind force, reduce the impact force on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com