Rail collecting device and method of seamless track quick track switching operating vehicle

A technology of seamless lines and retractable devices, applied to roads, tracks, laid tracks, etc., can solve problems such as low operating efficiency, inability to adapt to track changing work, and track drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

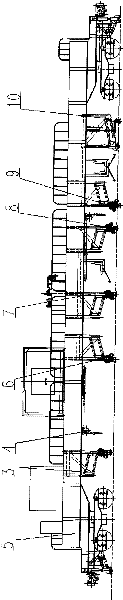

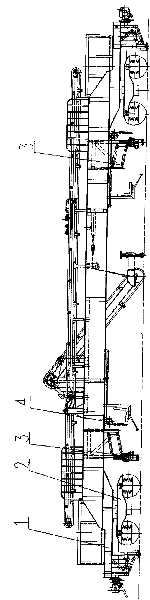

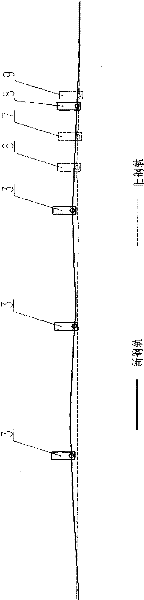

[0058] A rail retractable and retractable device for a seamless line rapid rail change operation vehicle, such as figure 1 , 2 As shown, the rail changing operation vehicle 5 and the auxiliary operation vehicle 1 are organized into groups, and the auxiliary operation vehicle 1 is located in the forward direction of the rail changing operation vehicle 5. The rail retracting device includes seven rail clamping devices, and each rail clamping device has the same structure. Positioning components, in which five rail clamping devices are suspended at intervals along the traveling direction of the vehicle body under the body of the rail changing operation vehicle 5, including rail clamping devices I3, rail clamping devices II6, There is one rail clamping device III7, one rail clamping device IV8 and one rail clamping device V9, and the other two are arranged under the auxiliary operation vehicle 1, which is the rail clamping device I3.

[0059]Rail clamping device Ⅰ3, rail clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com