Valve structure with pressure balance and water heater

A water heater and pressure technology, applied in the direction of balance valve, fluid heater, valve details, etc., can solve the problems of gas water heater flow faucet hot and cold, affecting bathing, etc., to avoid repeated flameout and ignition, ensure water temperature, and ensure Effect of outlet water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

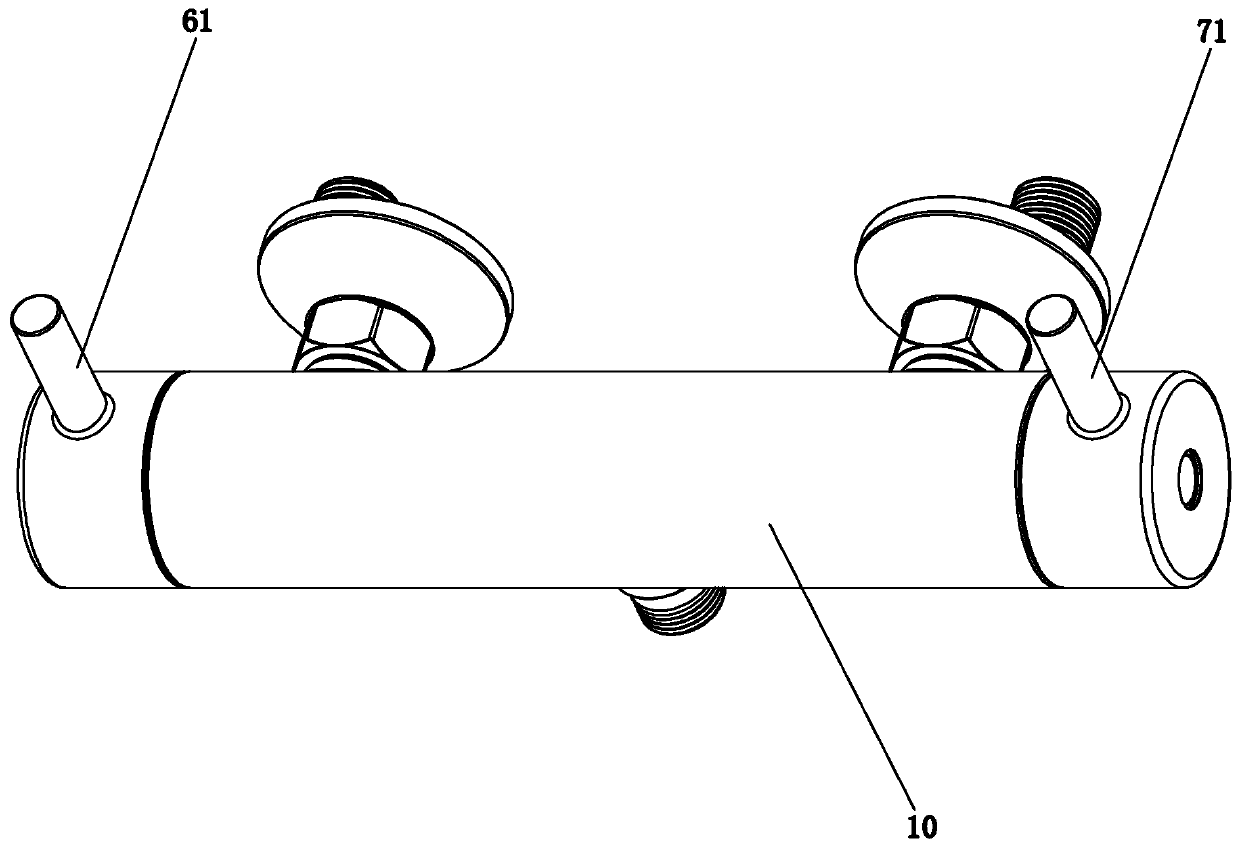

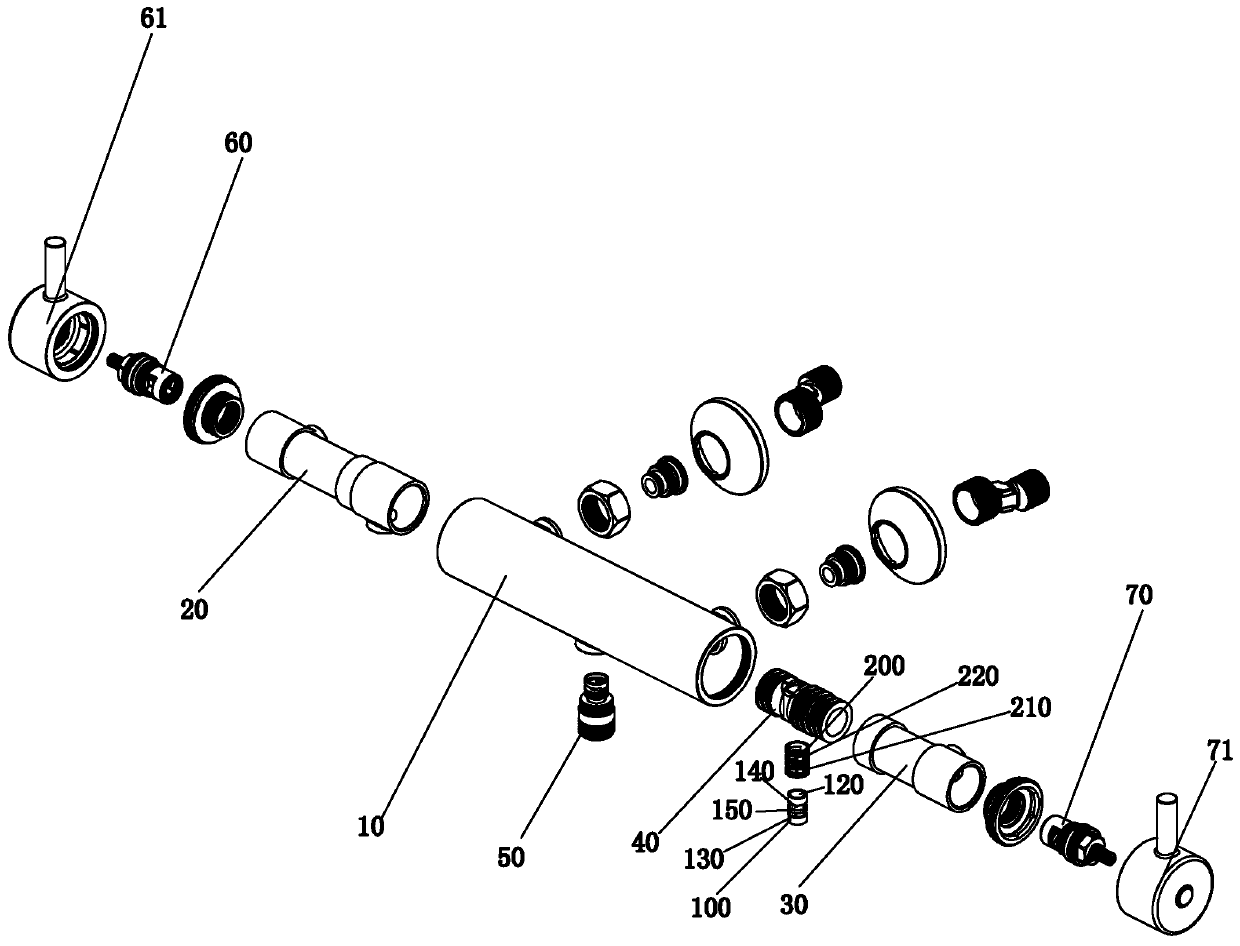

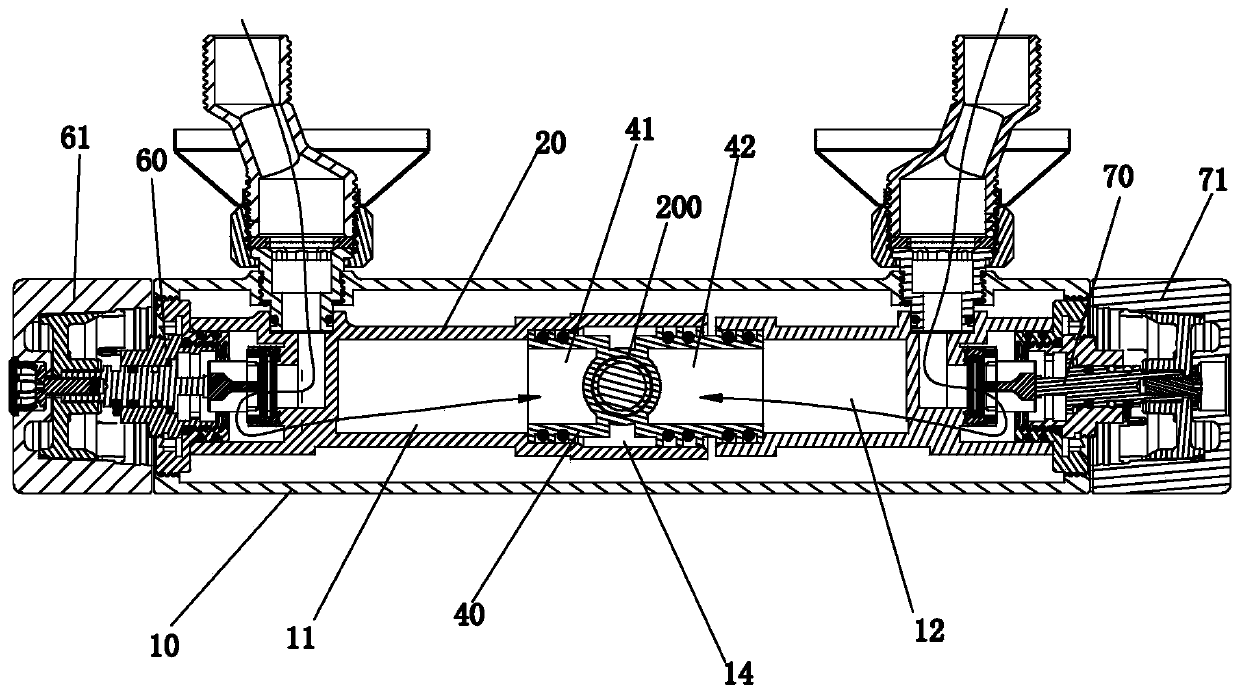

[0034] Please check Figure 1 to Figure 5 , The first preferred embodiment of the valve structure with pressure balance, the valve structure with pressure balance includes a fixed part and a pressure balance component.

[0035] The fixed part is provided with a first water inlet channel 11, a second water inlet channel 12, an assembly cavity 13, and a mixing cavity 14. The assembly cavity 13 is provided with a first perforation 131 connected with the first water inlet channel 11 and The second perforation 132 connected to the second water inlet channel 12.

[0036] In this embodiment, the fixed part includes a housing 10, a first valve seat 20, a second valve seat 30, a water mixing seat 40, and a water outlet connector 50. The first valve seat 20 and the second valve seat 30 are respectively fixed to the housing On both sides inside 10, the water mixing seat 40 is located in the housing 10 and connects the first valve seat 20 and the second valve seat 30, between the water mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com