Constant temperature water tank for calorimeter calibrating device

A technology of a verification device and a constant temperature water tank, which is applied to the measurement device, heat measurement, calorimeter, etc., can solve the problems of disturbing the water flow movement of the box, the water temperature of the water outlet of the box is not constant, and the detection of the heat meter is not accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

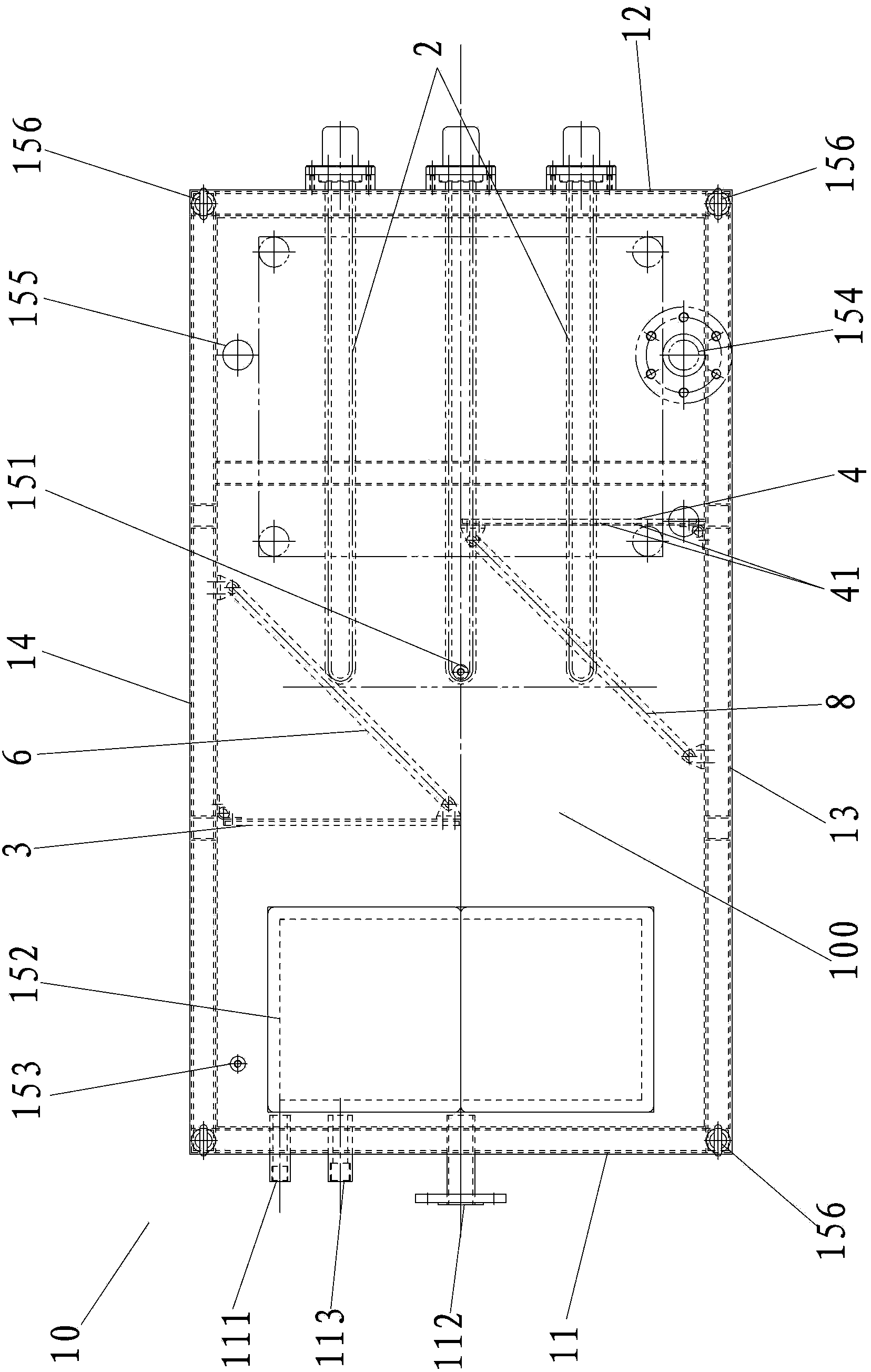

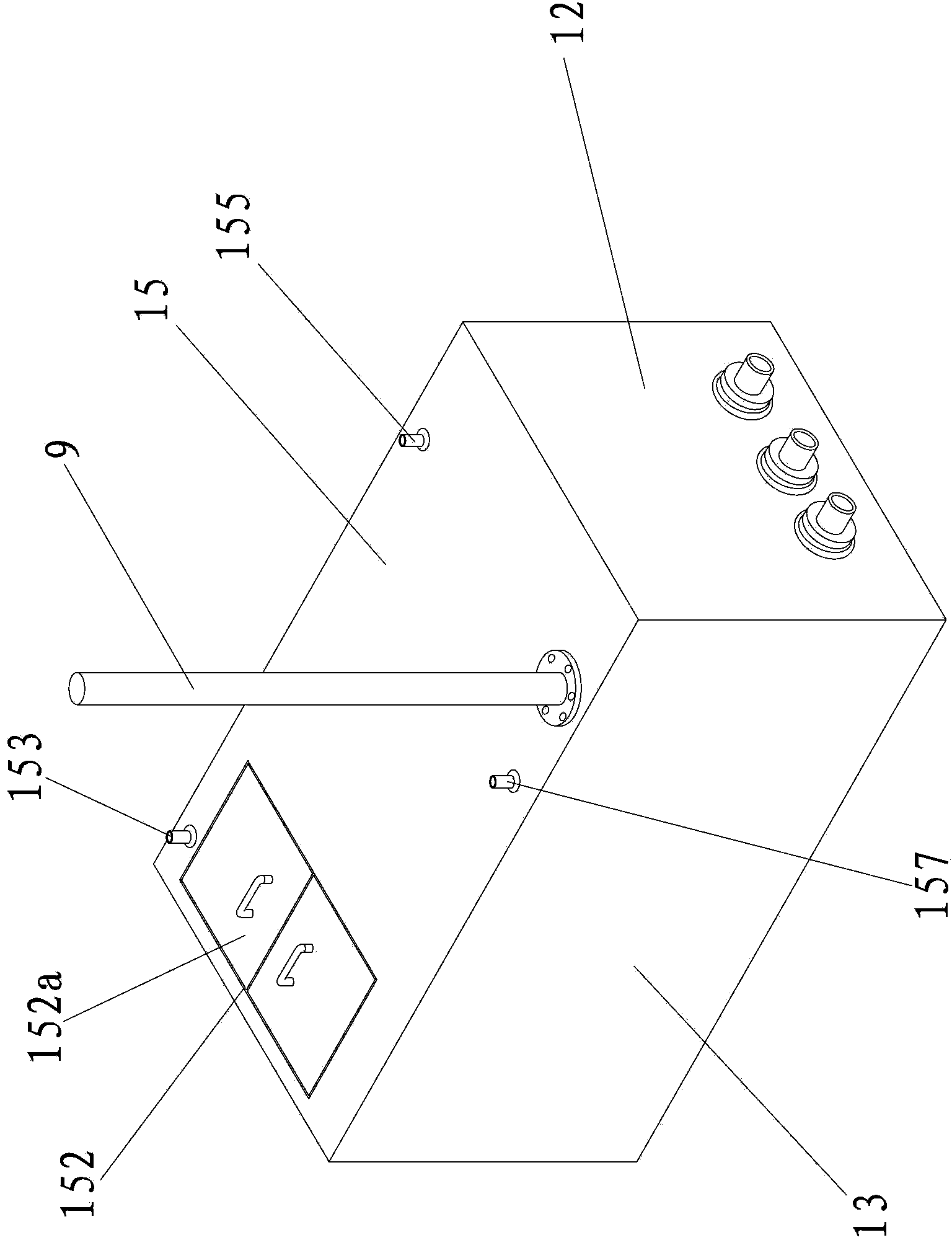

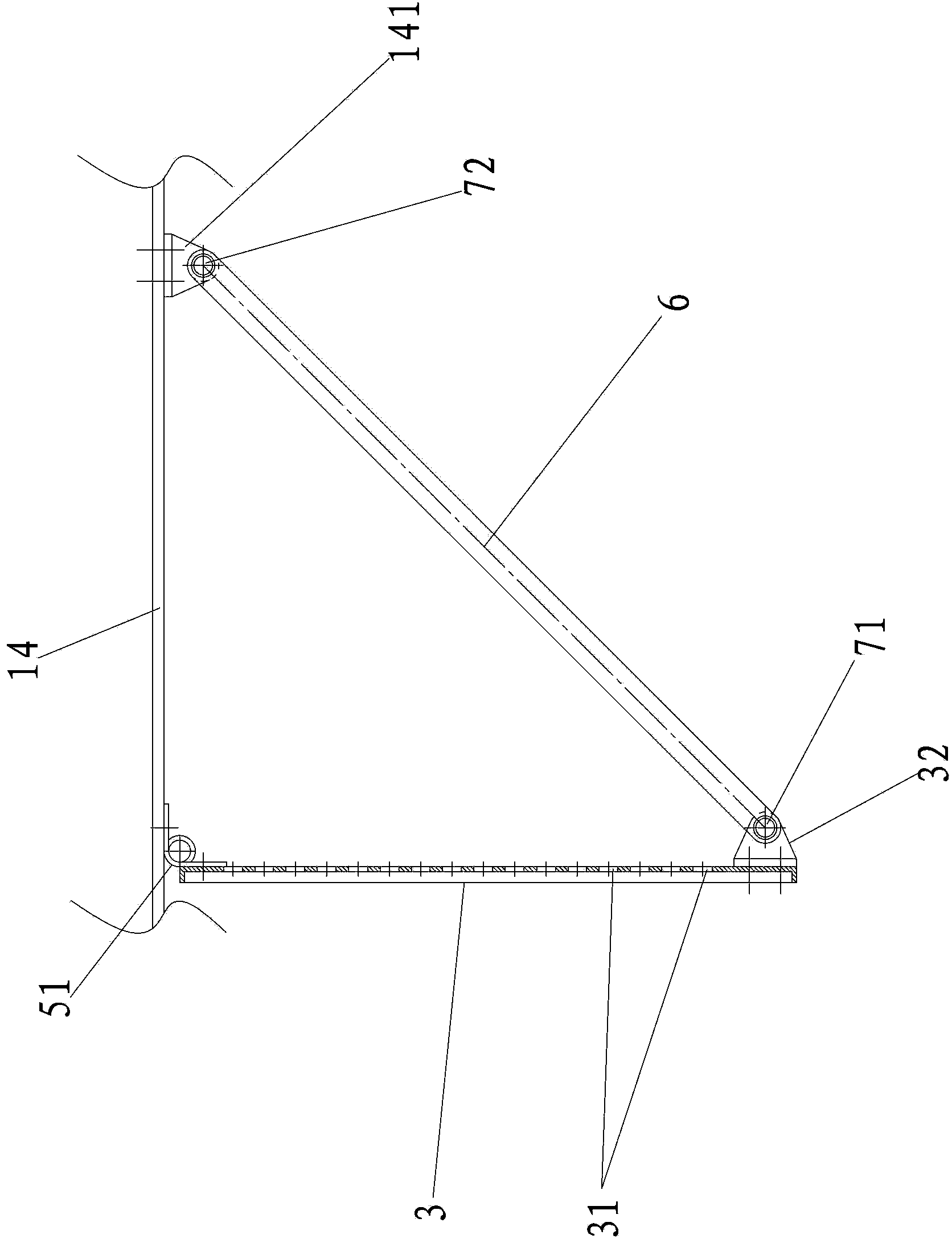

[0022] A constant temperature water tank for a calorimeter verification device of the present invention, such as Figure 1-4 Shown, comprise box body 10, and this box body 10 is surrounded by left side plate 11, right side plate 12, front side plate 13, rear side plate 14, upper top plate 15 and lower base plate (not shown in the figure). Hollow and airtight box body, the upper part of the left side plate 11 is provided with a cold water inlet 111 for external water to be injected into the box body, and the lower part of the left side plate 11 is opened with a hot water outlet 112 for hot water to flow out of the box body and for sewage drainage in the box body. Empty drain port 113, the box body 1 is provided with an electric heating element 2 at the right side of the box body 1, and the upper top plate 15 is provided with a temperature sensor installation port 151, an inspection inlet 152, and a water return port of the stabilized air getter tank 153. The water return port 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com