A Parameter Calibration Method for Joint Arm Coordinate Measuring Machine Based on Hybrid Optimization Algorithm

A coordinate measuring machine and optimization algorithm technology, applied in the field of precision measurement, can solve problems such as poor local search ability, accumulated errors, and many parameters, and achieve the effects of improving parameter calibration accuracy, measurement accuracy, and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

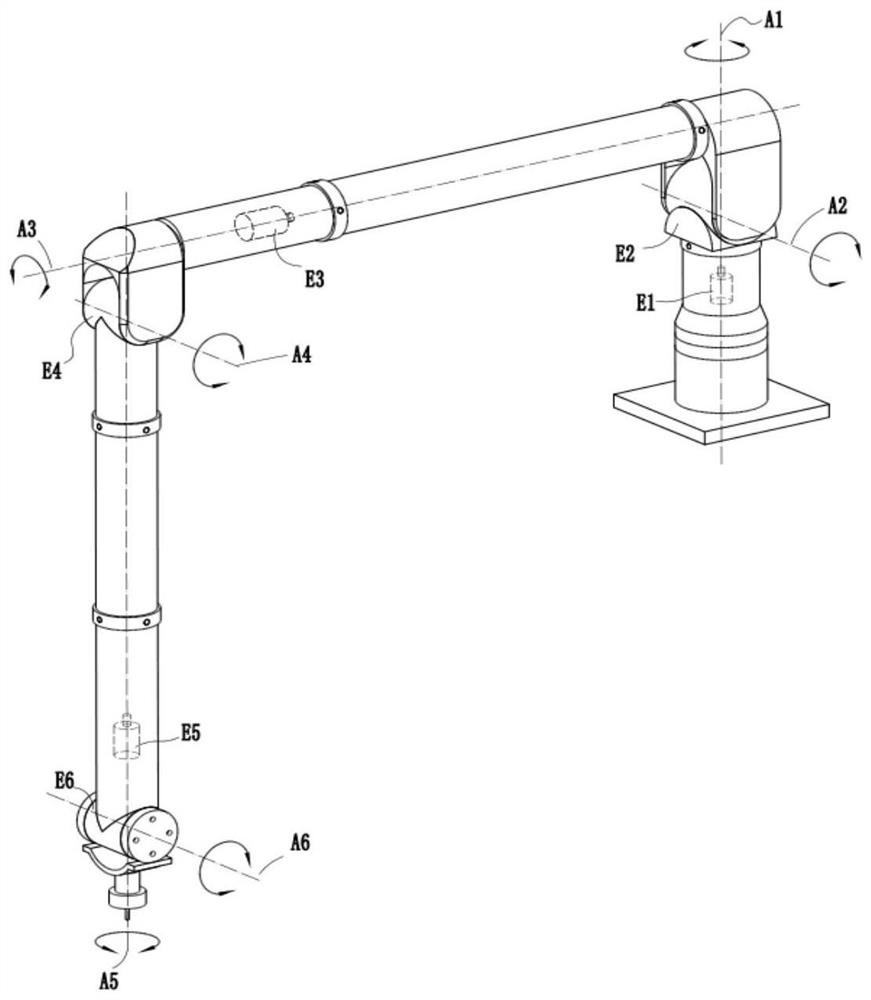

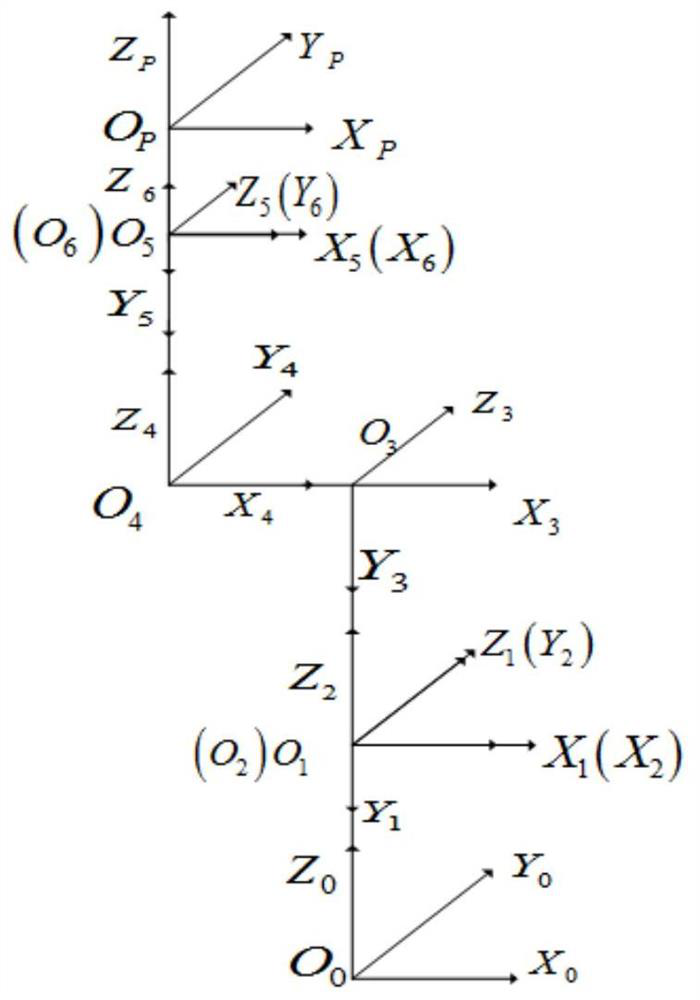

[0055] The present invention is aimed at the parameter calibration problem of an articulated arm coordinate measuring machine. The articulated arm coordinate measuring machine is a six-degree-of-freedom non-orthogonal coordinate measuring machine imitating a human arm. connected in series with a structure such as figure 1 As shown, in the research process of the present invention, the nominal values of the structural parameters of the articulated arm coordinate measuring machine used are shown in Table 1.

[0056] Table 1 Nominal values of the structural parameters of the articulated arm coordinate measuring machine

[0057]

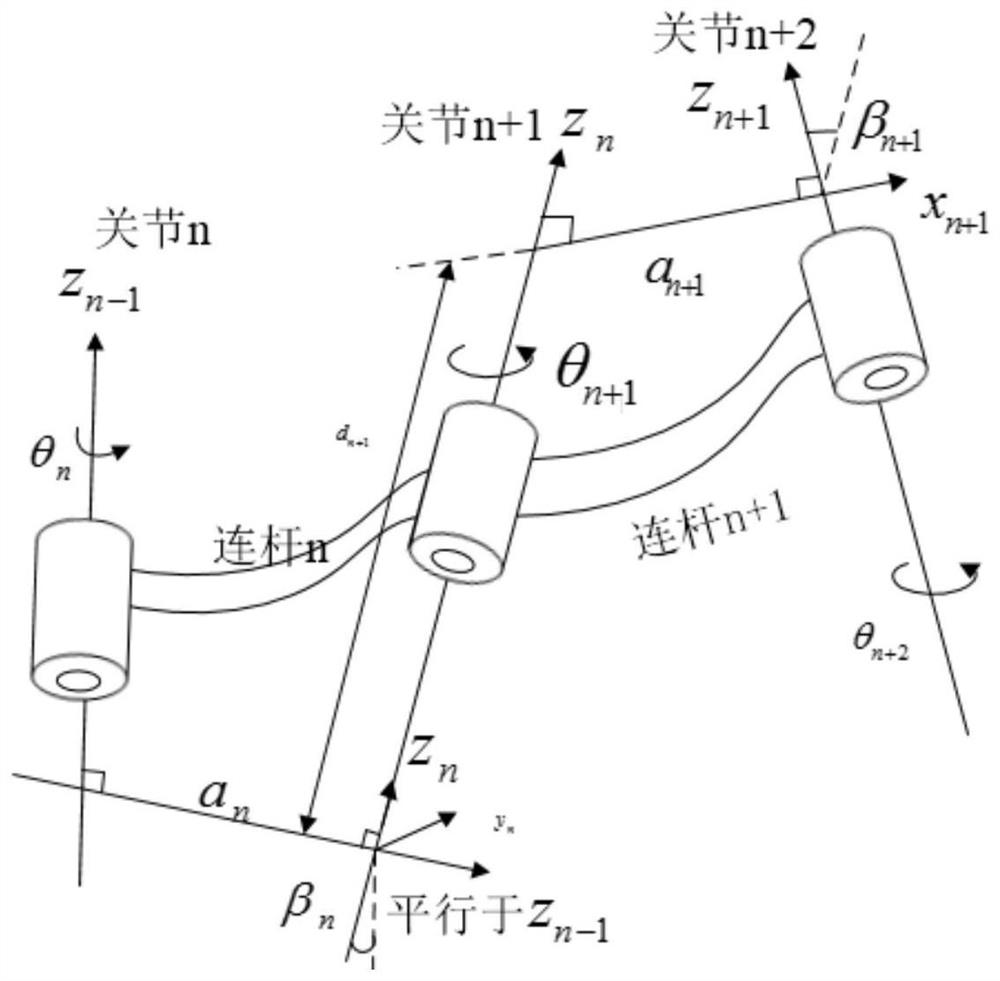

[0058] Table 1, θ i Indicates the joint rotation angle, a i Indicates the member length, d i Indicates the member offset, β i Indicates the torsion angle of the member.

[0059] For the above-mentioned articulated arm coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com