Electronic rotor mechanism

A technology of electronic rotor and rotating shaft, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of iron core material waste, heavy weight, and increase the overall weight of electronic motors, etc., and achieve reduction Small weight, the effect of reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

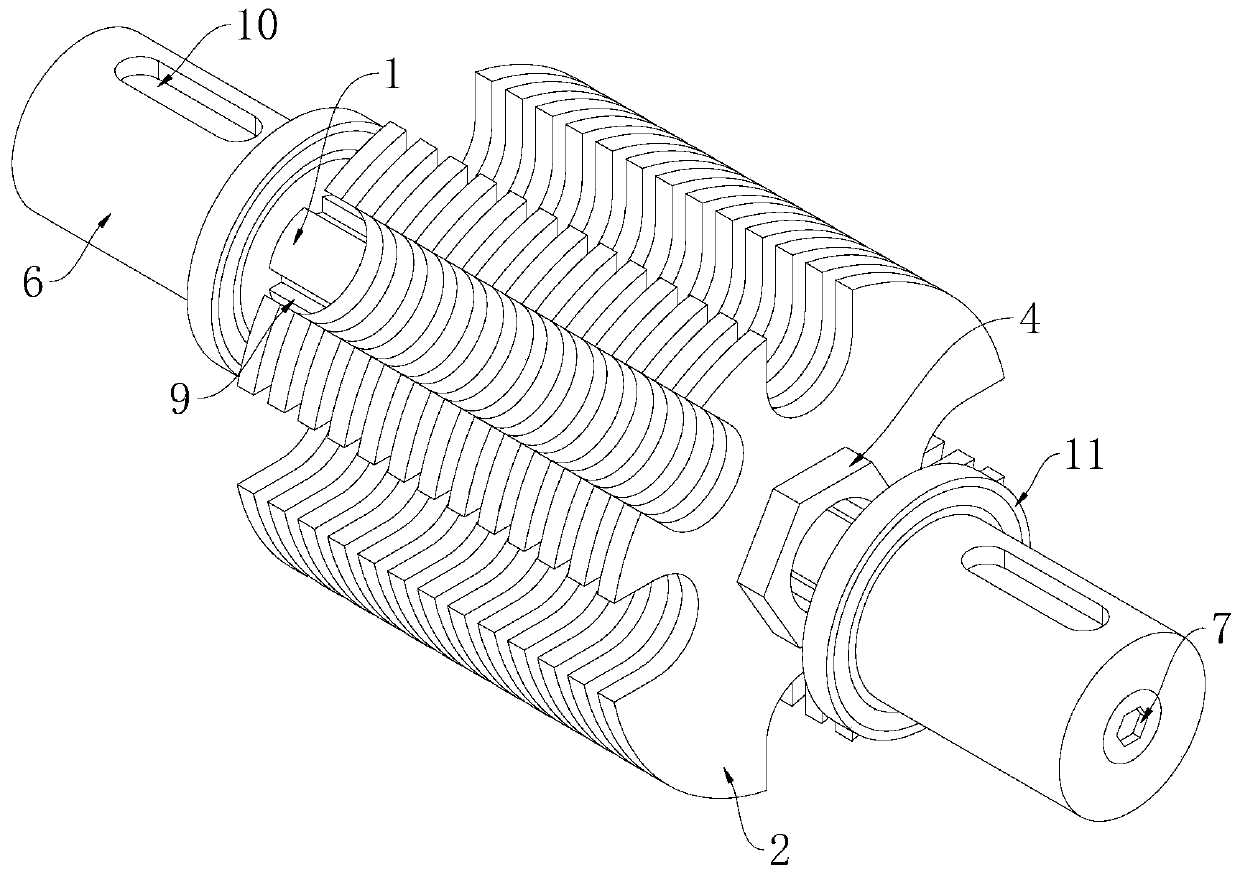

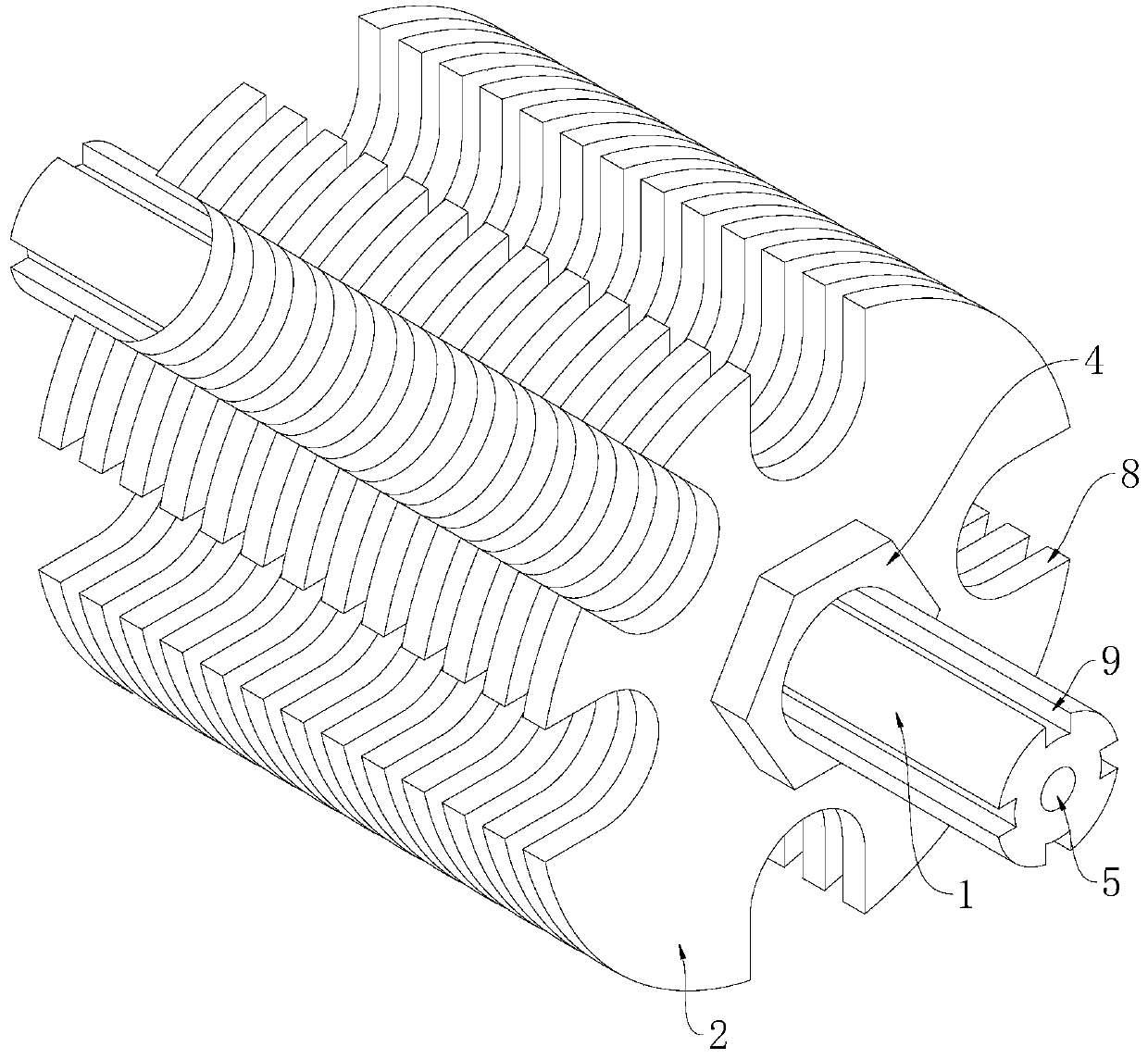

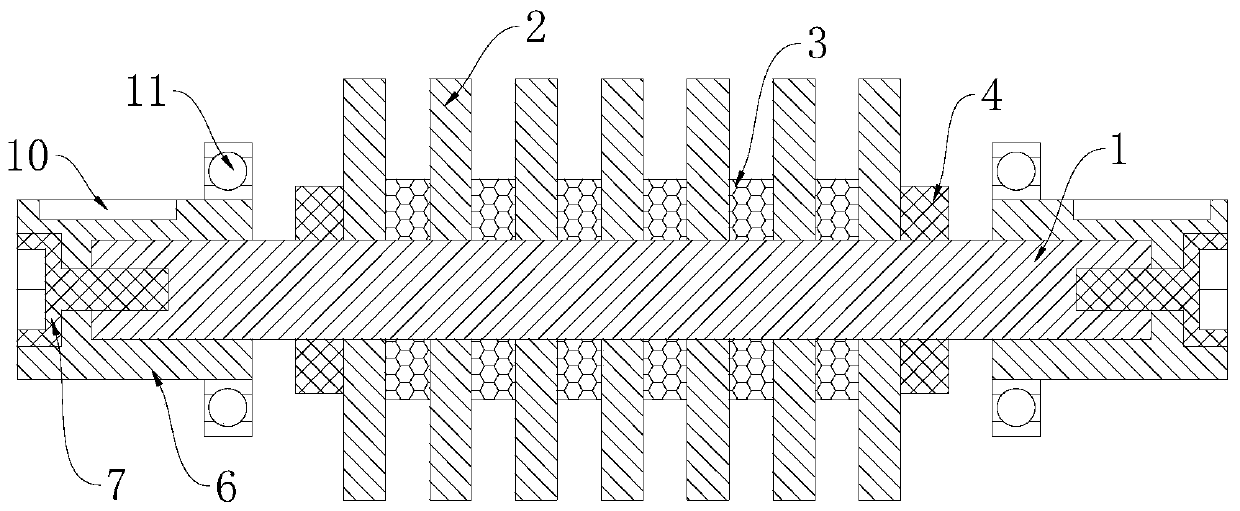

[0022] Example: such as figure 1 , figure 2 and image 3 As shown, an electronic rotor mechanism of the present invention includes a rotating shaft 1 and several fixed steel sheets 2, and several fixed steel sheets 2 are all slidably sleeved on the outer surface of the rotating shaft 1, and two adjacent fixed steel sheets 2 The sliding sleeve on the rotating shaft 1 between them is provided with spacer steel sheets 3, and the two ends of the outer surface of the rotating shaft 1 are all threaded with fastening nuts 4, and the opposite sides of the two fastening nuts 4 are respectively connected to the rotating shaft 1. The fixed steel sheets 2 at both ends are tightly fitted, the middle part of both ends of the rotating shaft 1 is provided with a threaded hole 5, and the two ends of the rotating shaft 1 are movably sleeved with a rotating shaft cap 6, and the middle parts of the opposite sides of the two rotating shaft caps 6 are arranged. Jacks are provided, fastening bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com