Sugarcoated fruit core-removing and stringing device

A candied haws and stringing technology, applied in the field of candied haws production equipment, can solve the problems of no specific research on the candied haws stringing process, unsuitable for large-scale promotion, and cumbersome combination of large machines, etc. Maintenance, the effect of slow process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

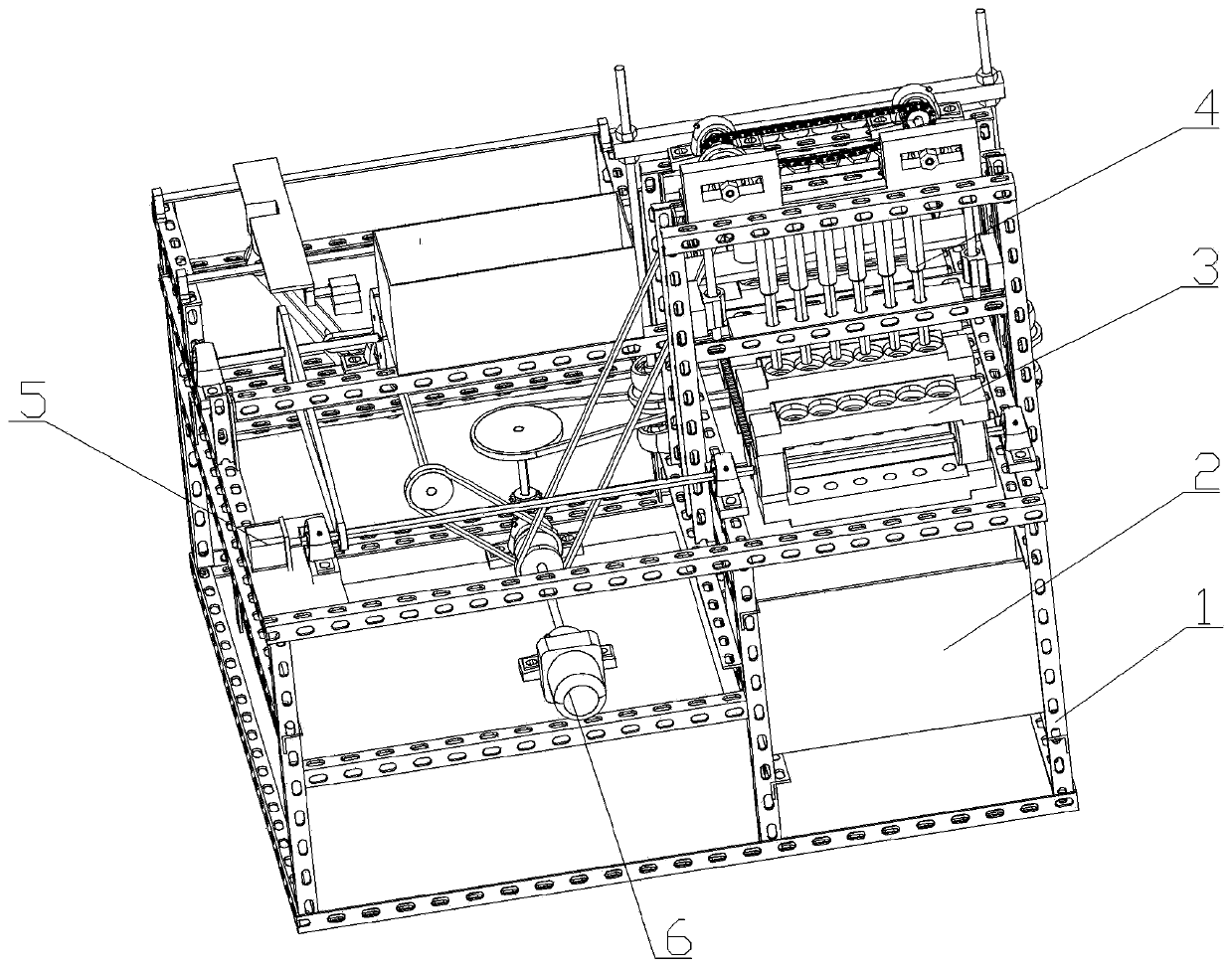

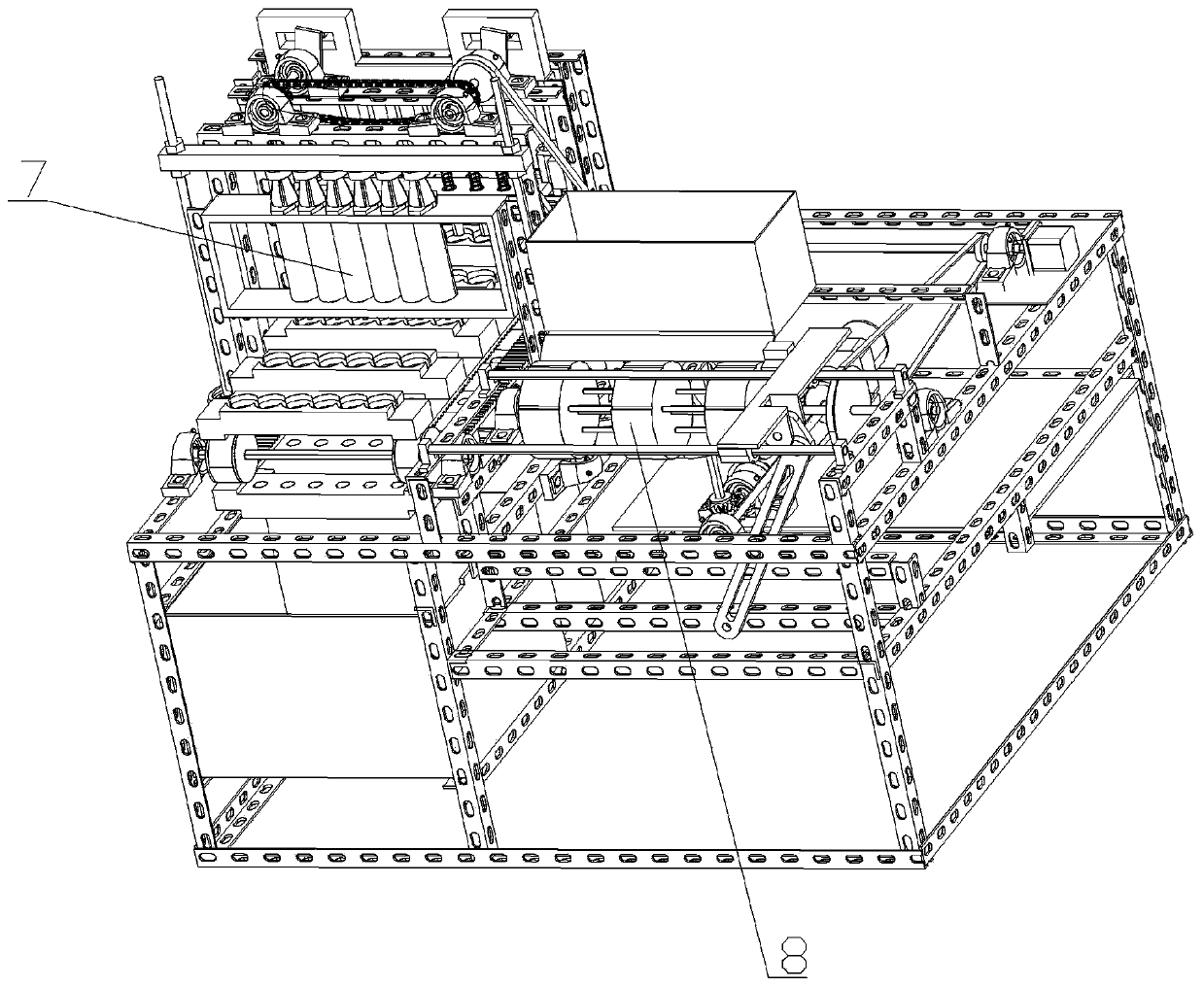

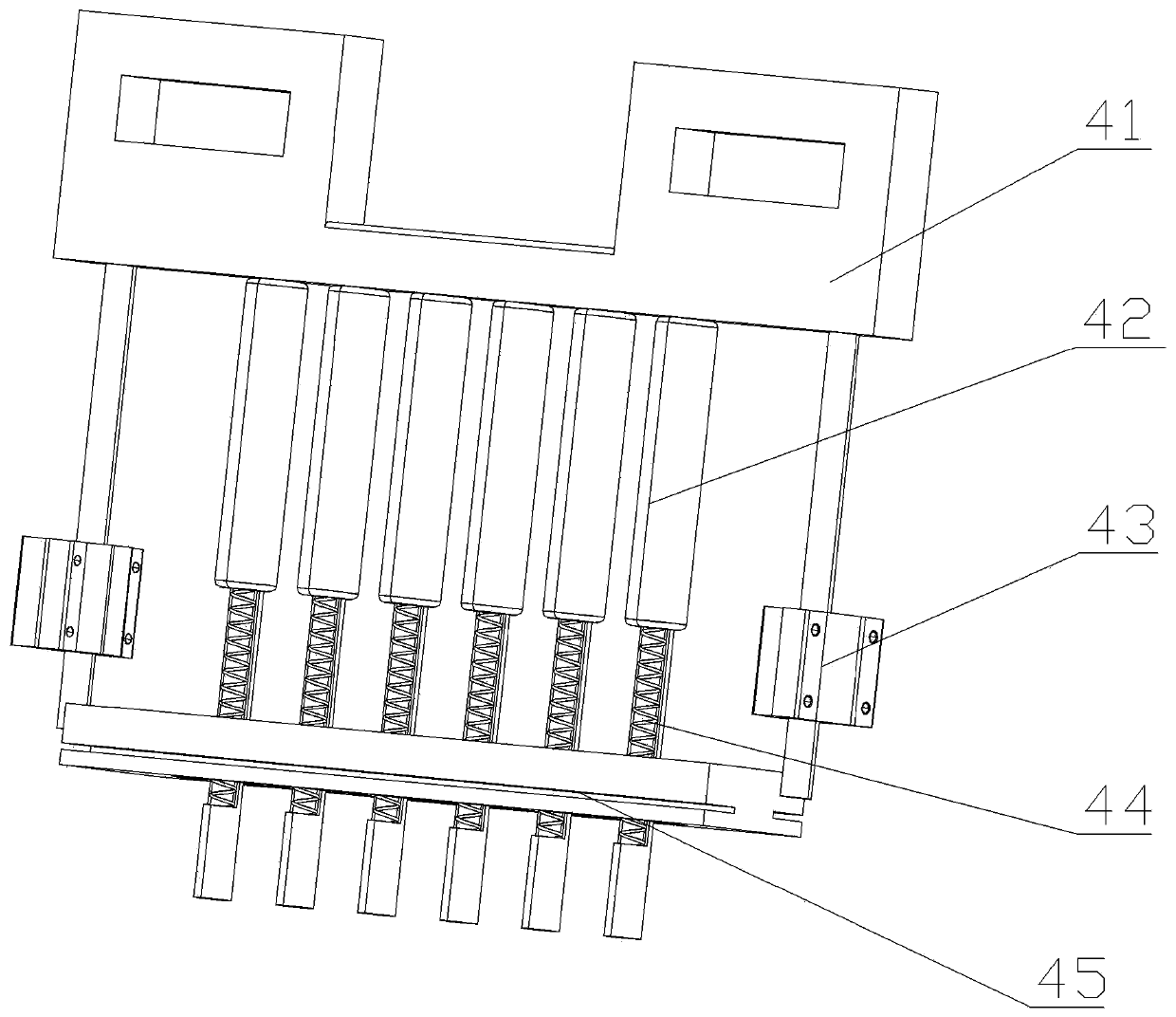

[0032] Such as Figure 1-6 As shown, the candied haws core removal and stringing device includes a frame 1 and a positioning and conveying mechanism 3 arranged on the frame 1, a punching and core removal mechanism 4, a quantitative filling mechanism 7, a precise stringing mechanism 8 and a driving mechanism. The perforating and core-removing mechanism 4 and the quantitative stuffing mechanism 7 are sequentially arranged on the upper end of the positioning conveying mechanism 3 from front to back, and the precise threading mechanism 8 is arranged on one side of the positioning conveying mechanism 3 and is in phase with the positioning conveying mechanism 3. Corresponding to facilitate precise threading. The driving mechanism is arranged on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com