Self-service vending machine quality detecting table for film pressing picture color fading preventing of Thangka unlined upper garment customization

A technology of self-service vending machines and Thangka shirts, which is applied to coin-free or similar appliances, coin-operated equipment with instrument control, printing machines, etc. Reduce the wearing comfort of shirts and other problems, and achieve the effect of enhanced tensile resistance and light quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

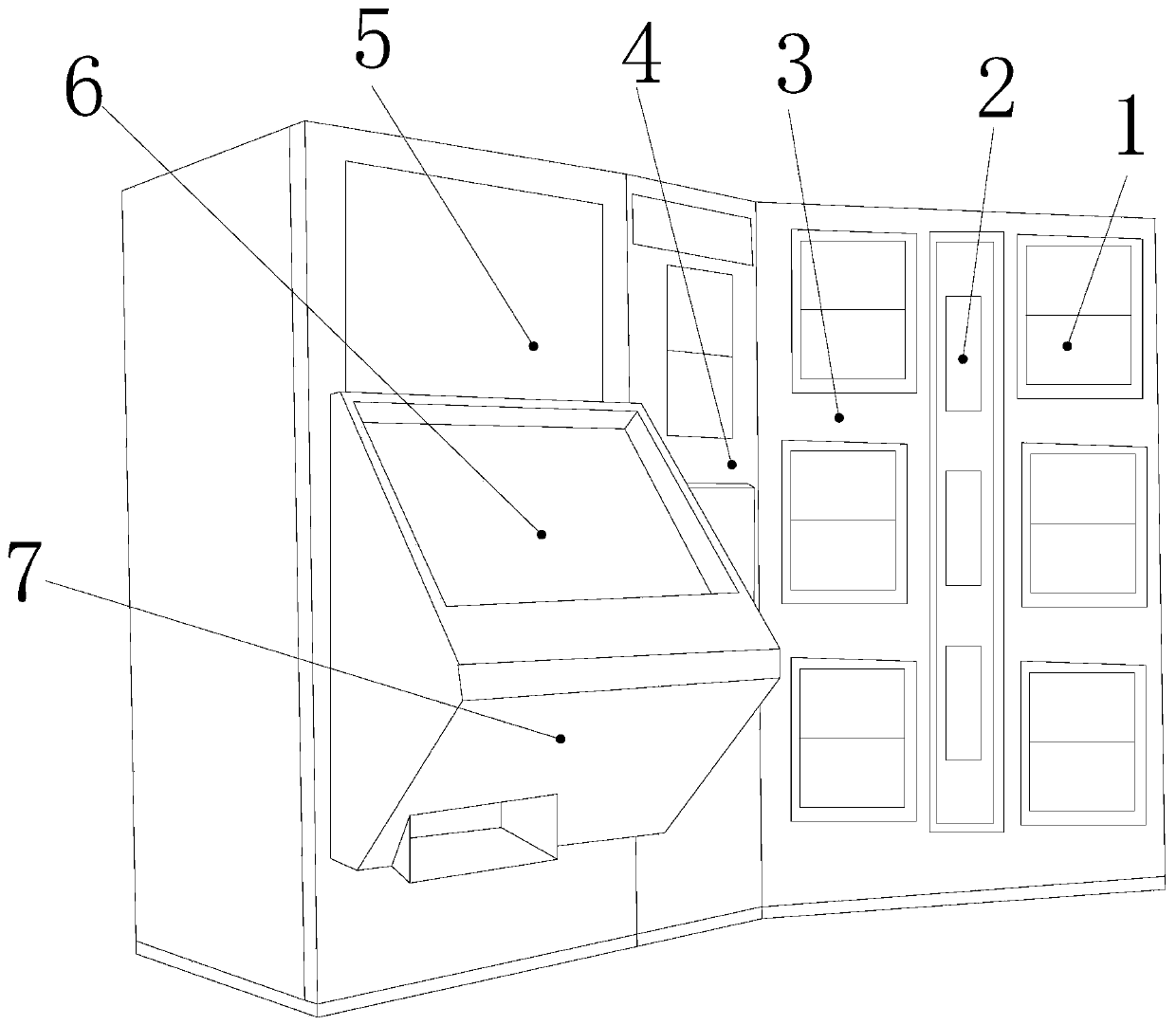

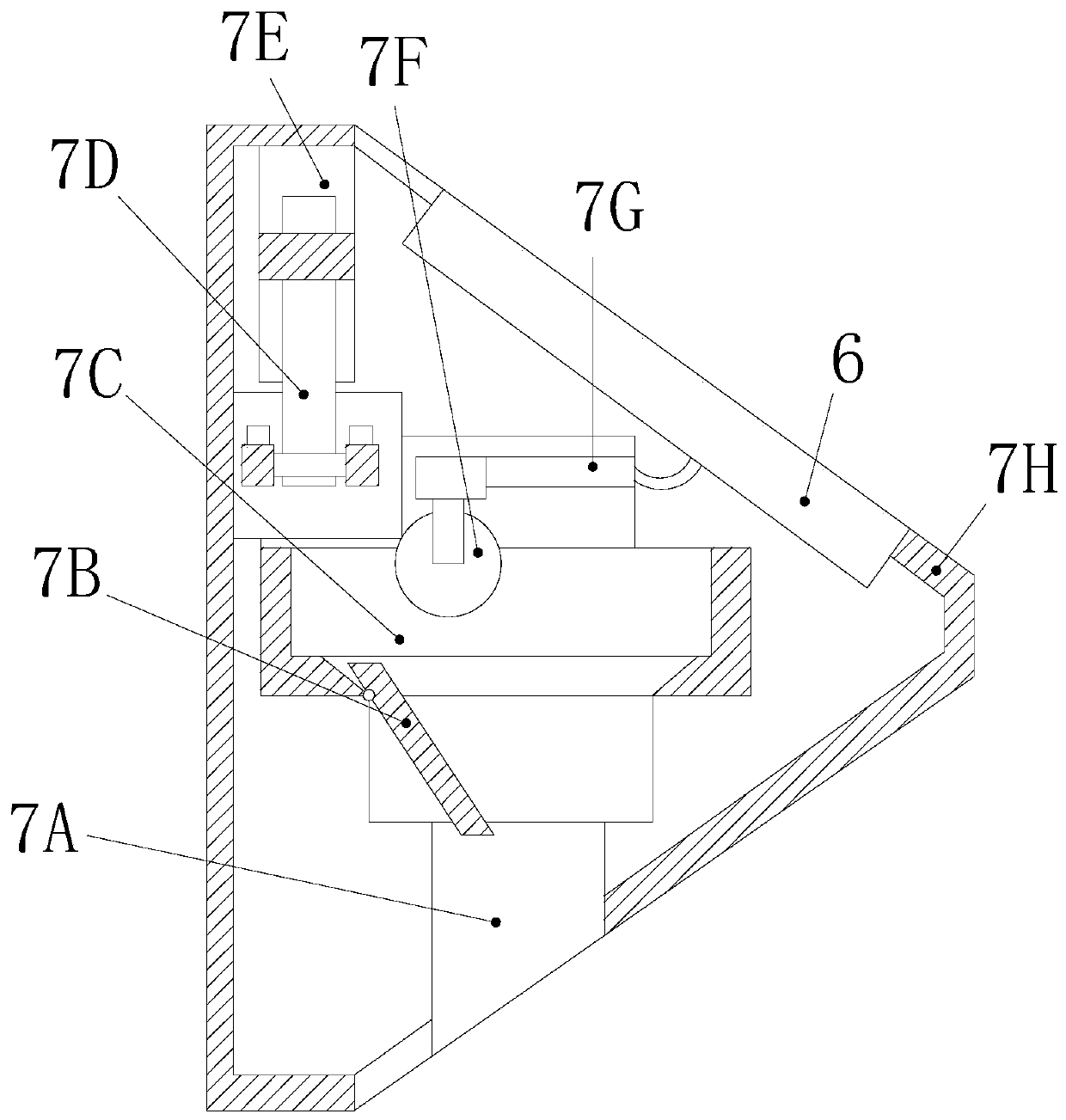

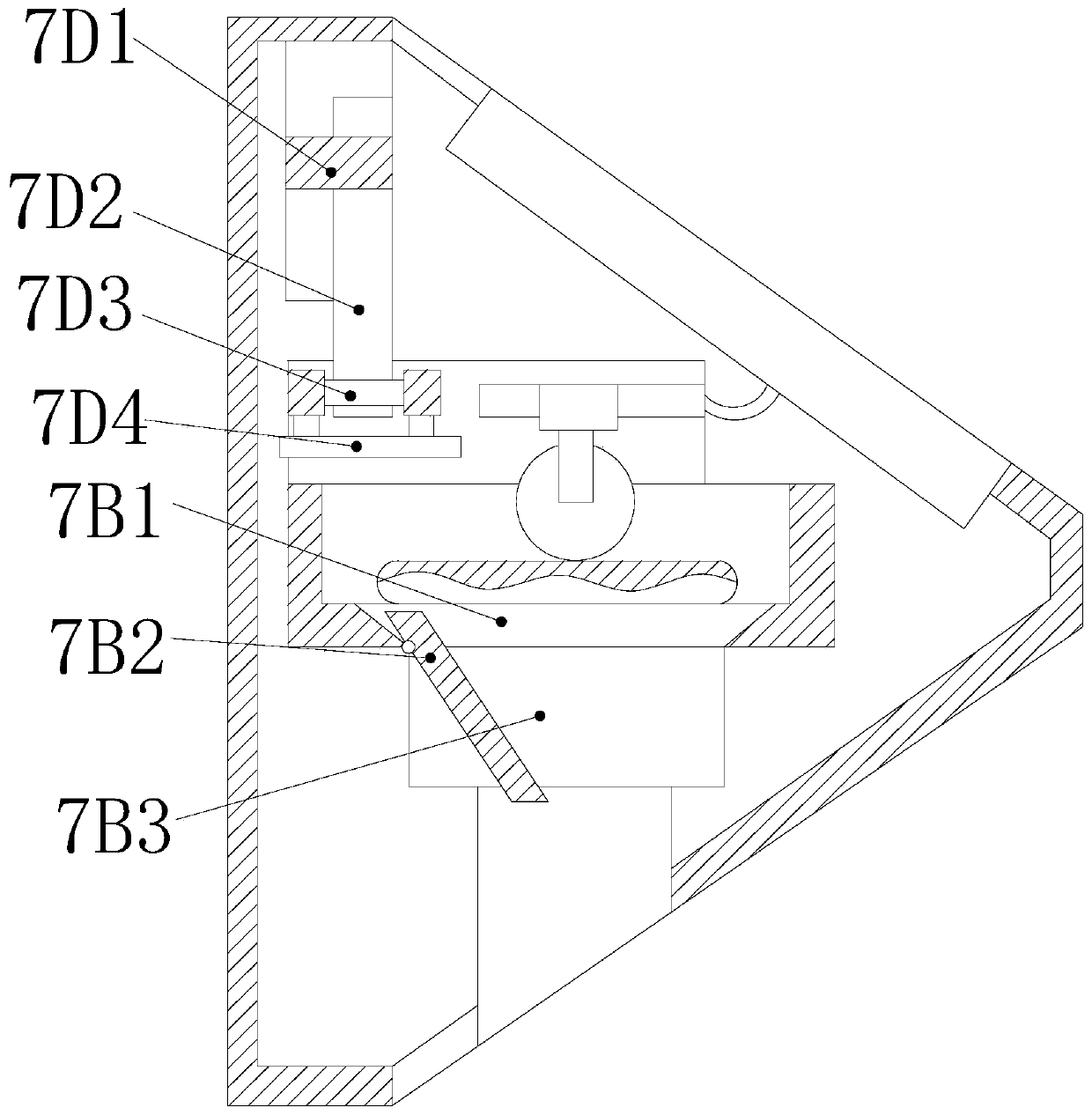

[0031] see Figure 1-Figure 7 , the present invention provides a self-service vending machine quality inspection platform with custom-made film pressure map anti-fading for Thangka shirts. The printing tank chamber 5, the human-machine interface screen 6, and the membrane pressing roller mechanism 7, the membrane pressing roller mechanism 7 is close to the front side of the hot stamping tank chamber 5, the human-machine interface screen 6 and the membrane pressing roller Mechanism 7 is electrically connected, and the hot stamping tank chamber 5 is welded together with the locker 3 through the cross channel tank connection cabinet 4 and communicates with each other. Inside, the human-machine interface screen 6 is installed on the front side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com