High-strength impact-resistant composite sleeve

A composite sleeve and impact-resistant technology, which is applied in the direction of pipeline protection, tubular objects, pipeline damage/wear prevention, etc., can solve the problems of insufficient impact resistance, rupture, and uneven force of the sleeve, so as to improve the impact resistance. Improve the compression resistance and reduce the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

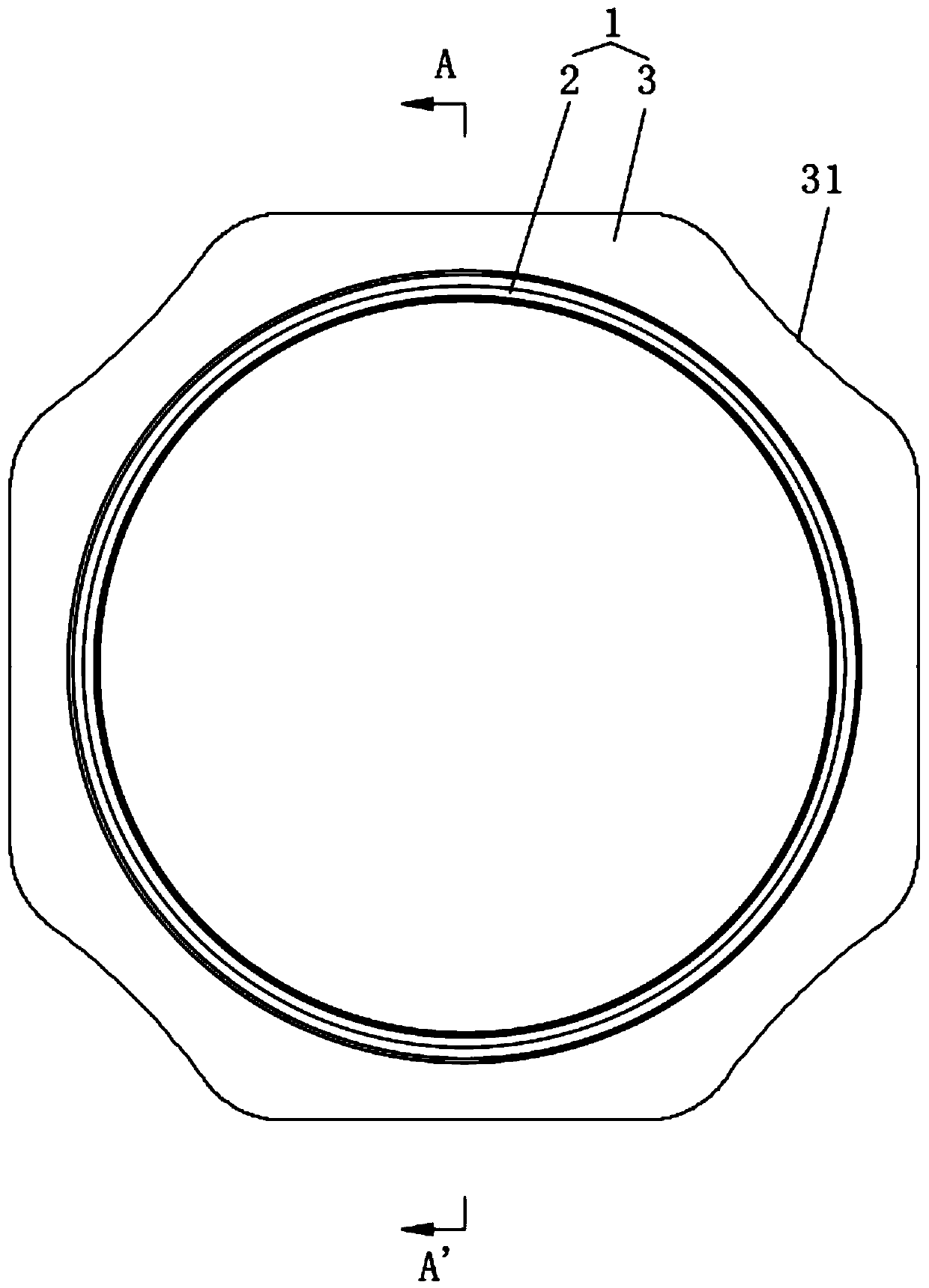

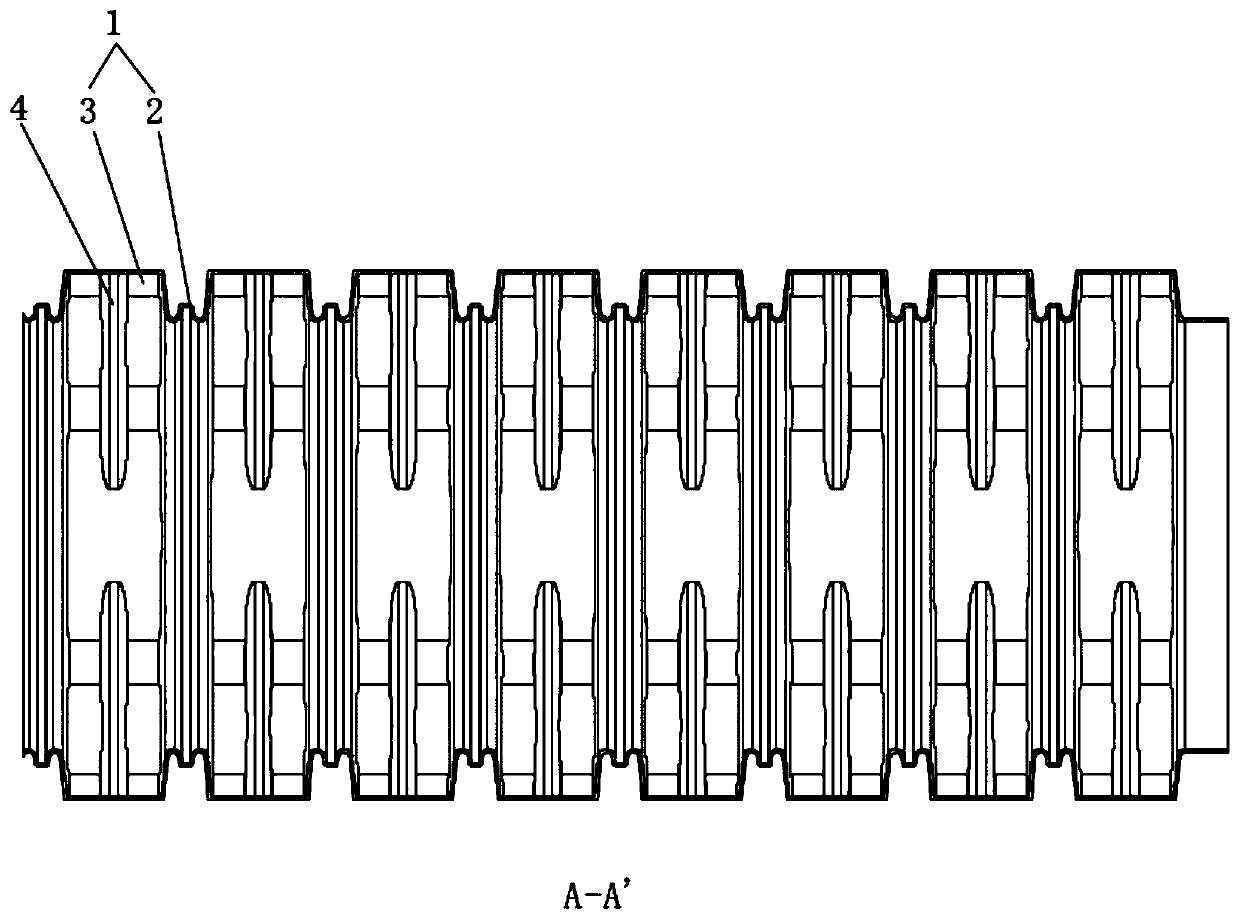

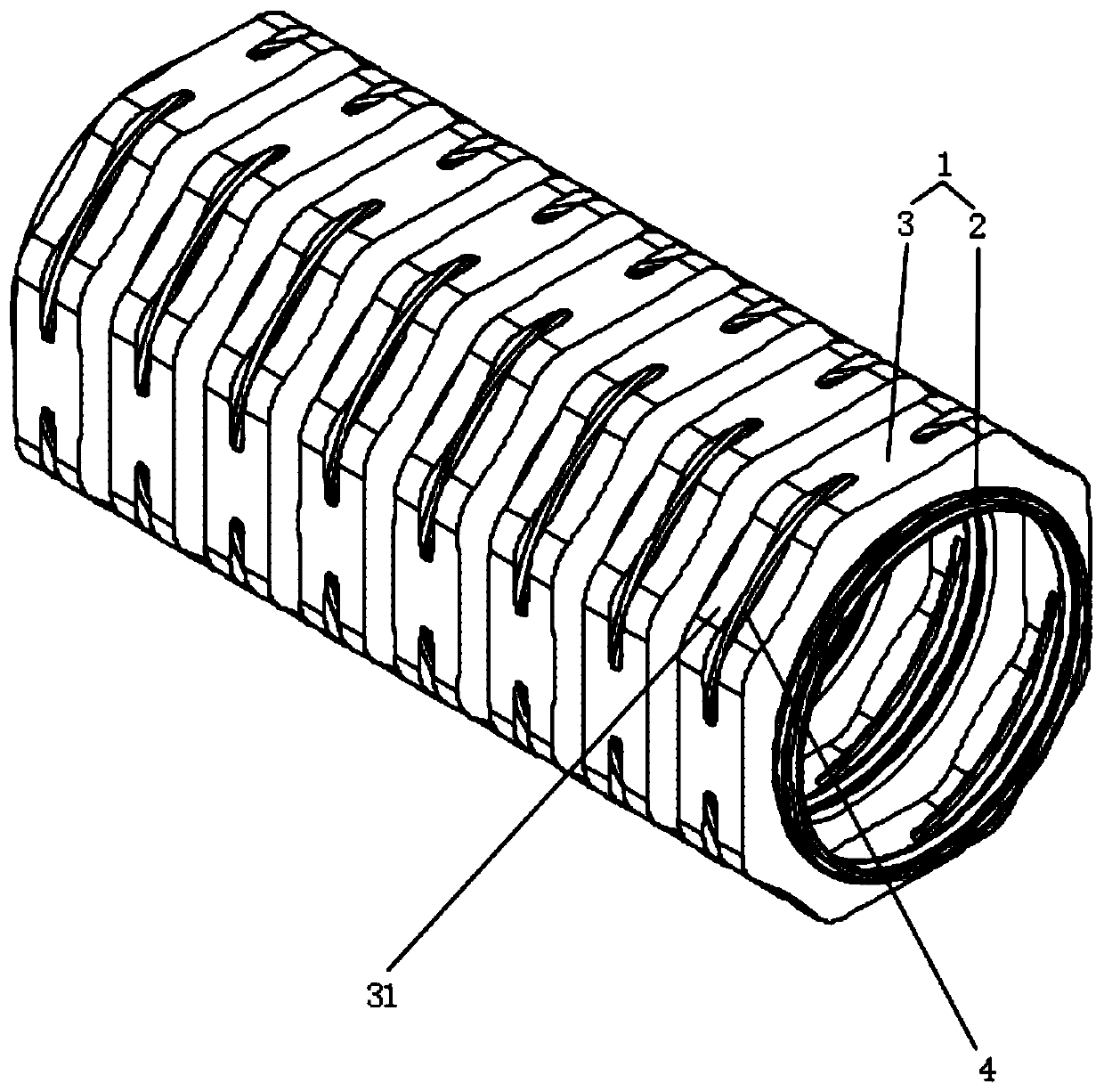

[0047] like Figure 1 to Figure 3As shown, a high-strength impact-resistant composite casing includes a main pipe 1, the main pipe 1 includes a pipe body 2 and a plurality of reinforcement blocks 3 sleeved on the outer periphery of the pipe body 2, and the reinforcement blocks 3 are sequentially arranged along the axial direction of the pipe body 2. Arranged, the cross section of the reinforcing block 3 is rectangular, and the corners of the reinforcing block 3 are recessed to form grooves 4 .

[0048] The groove wall of the groove 4 at the corner of the reinforcement block 3 is equivalent to the corner reinforcement rib of the reinforcement block 3, which can improve the compressive performance at the corner of the reinforcement block 3; at the same time, setting the groove 4 can reduce the strength of the reinforcement block 3 corners. In order to achieve the effect of improving the compressive capacity of the corners of the reinforcement block 3, and prevent the corners of ...

Embodiment 2

[0052] like Figure 4 and Figure 5 As shown, the high-strength impact-resistant composite casing also includes a straight inner tube 5 arranged inside the main pipe 1 , and the straight inner tube 5 is connected to the inner wall of the tube body 2 . The present invention has a double wall through the straight inner tube 5, which further improves the compression resistance of the present invention; at the same time, the straight inner tube 5 can make the inner wall of the present invention smooth, and when the present invention is used as a cable protection tube, it can facilitate The user threads; and when the present invention is used as a sewage pipe, the smooth inner wall can reduce the resistance of the casing to sewage.

[0053] like Figure 5 As shown, one end of the straight inner pipe 5 is provided with a connecting pipe 6 protruding from the main pipe 1, and the outer periphery of the connecting pipe 6 is provided with corrugations 61, and the cross section of the...

Embodiment 3

[0055] like Image 6 and Figure 7 As shown, in this embodiment, the high-strength impact-resistant composite sleeve also includes a straight outer tube 7, the main pipe 1 is arranged inside the straight outer tube 7, and all reinforcing blocks 3 are connected to the straight outer tube 7. inner wall connections. When the present invention is used, the groove 4 and the space between the two reinforcing blocks 3 are easy to hide dirt and dirt, making it inconvenient for users to clean. In the present invention, a straight outer tube 7 is arranged outside the main pipe 1, so that the user is easy to clean.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com