Method for testing low-cycle repeated load anti-seismic performance of light steel frame composite wall structure

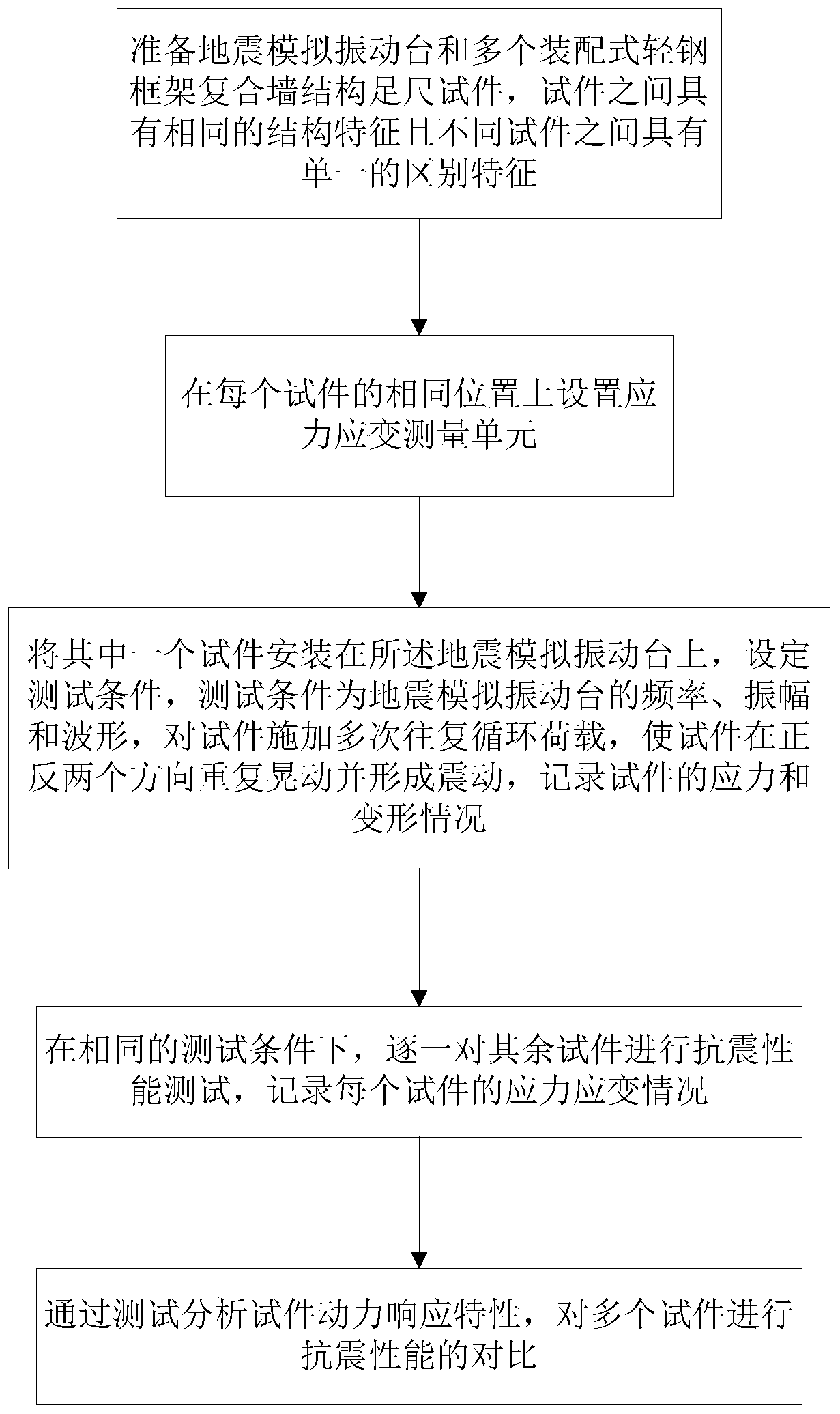

A low-cycle repetitive load and seismic performance technology, which is applied in the testing of machine/structural components, vibration testing, measuring devices, etc., can solve the problem of a single method, which cannot be combined with wall structure testing and comparison, and low-cycle repetitive load seismic performance test data Incomplete and other issues, to achieve the effect of complete data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] S1: Prepare seismic simulation shaking table and five full-scale test pieces of fabricated light steel frame-composite wall structure. The five assembled light steel frame-composite wall structure full-scale specimens are the first specimen FG1, the second specimen FG1+Q, the third specimen FG1+QC, the fourth specimen FG1+QM, and the fifth specimen. Pieces of FG1+HJ.

[0040] The first test piece FG1 is made of an empty frame;

[0041] The second test piece FG1+Q is made of an empty frame and a composite wall panel embedded in the empty frame;

[0042] The third test piece FG1+QC is made of an empty frame and a composite wall panel with windows embedded in the empty frame;

[0043] The fourth test piece FG1+QM is made of an empty frame and a composite wall panel with a door hole embedded in the empty frame;

[0044] The fifth test piece FG1+HJ is made of an assembling anti-seismic element embedded between the empty frame and the column beams on both sides of the empty frame. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com