Patents

Literature

62 results about "Full scale test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

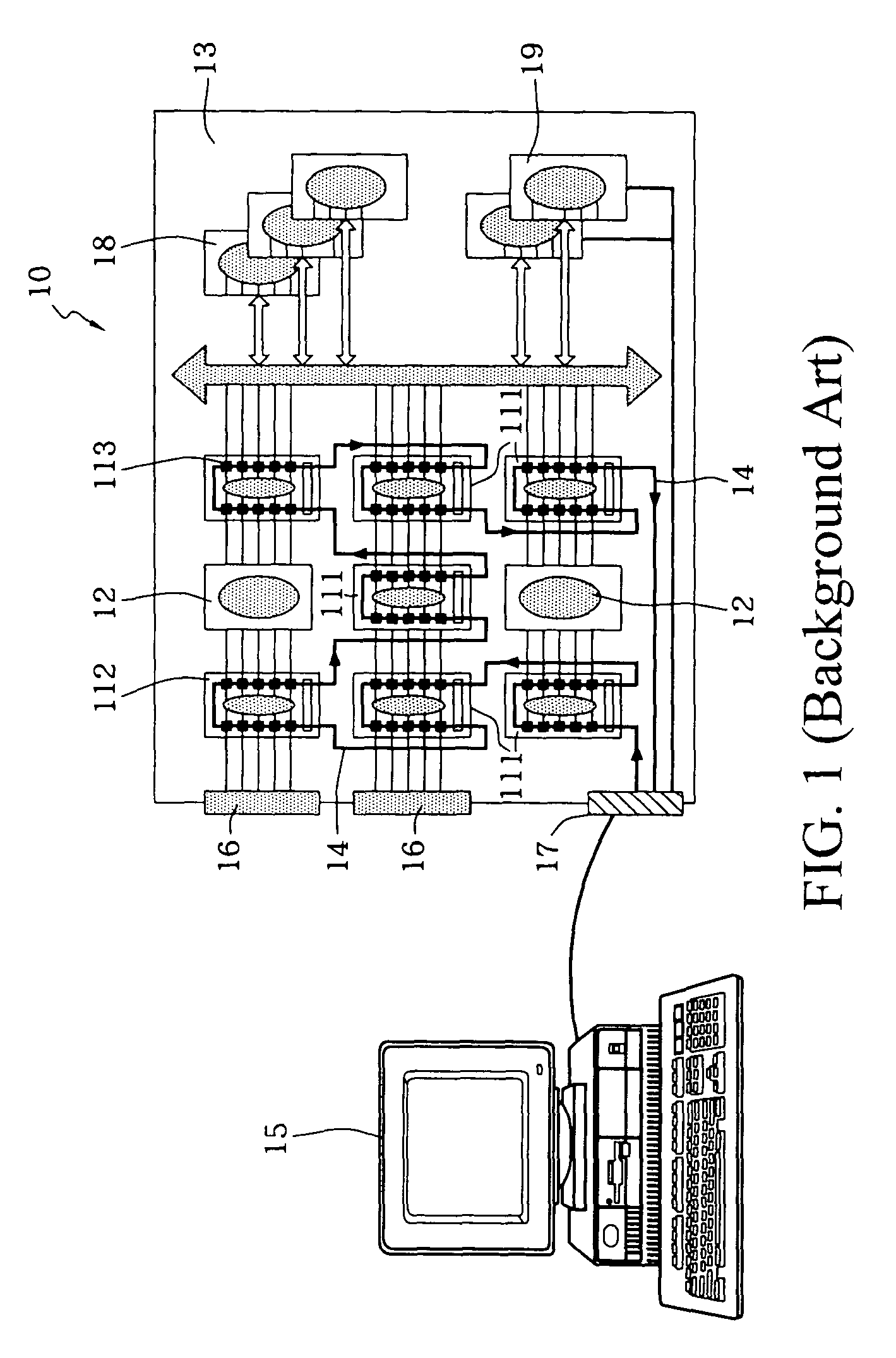

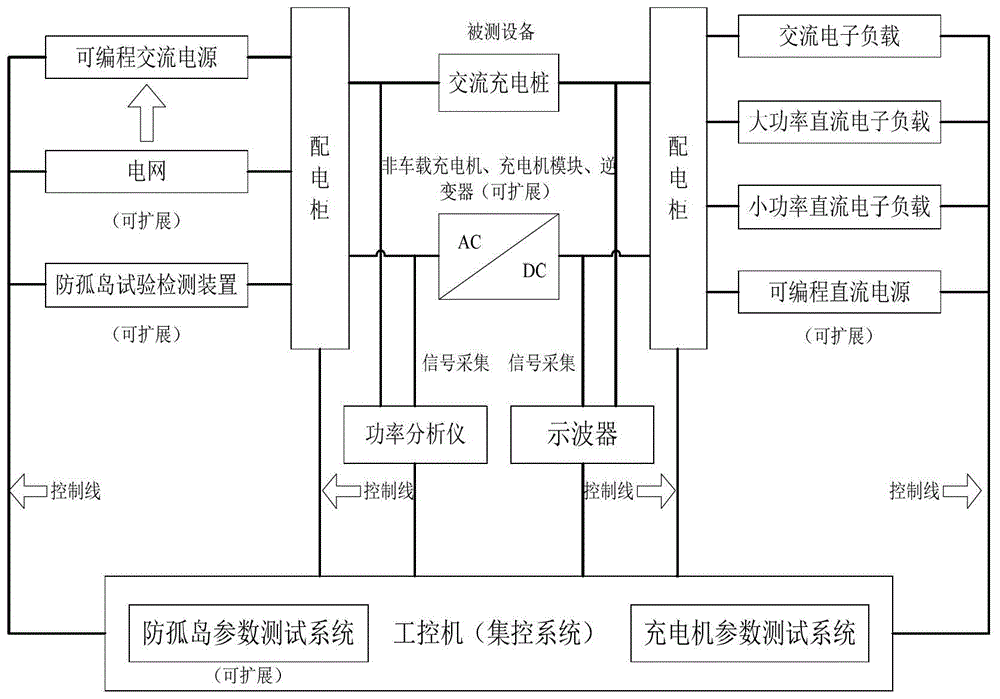

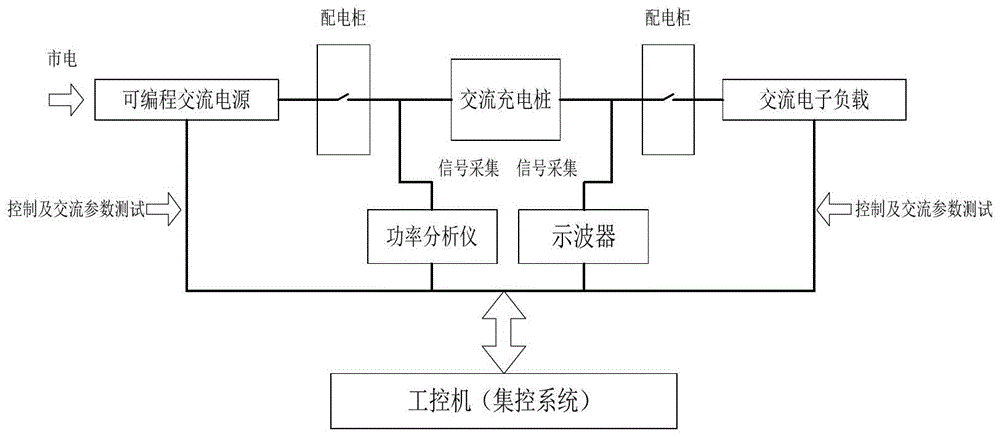

Method and system of automatic testing of electric automobile charging facilities

ActiveCN103257286AMeet the requirements of testing specificationsAchieve combinationElectrical testingPerformance indexEngineering

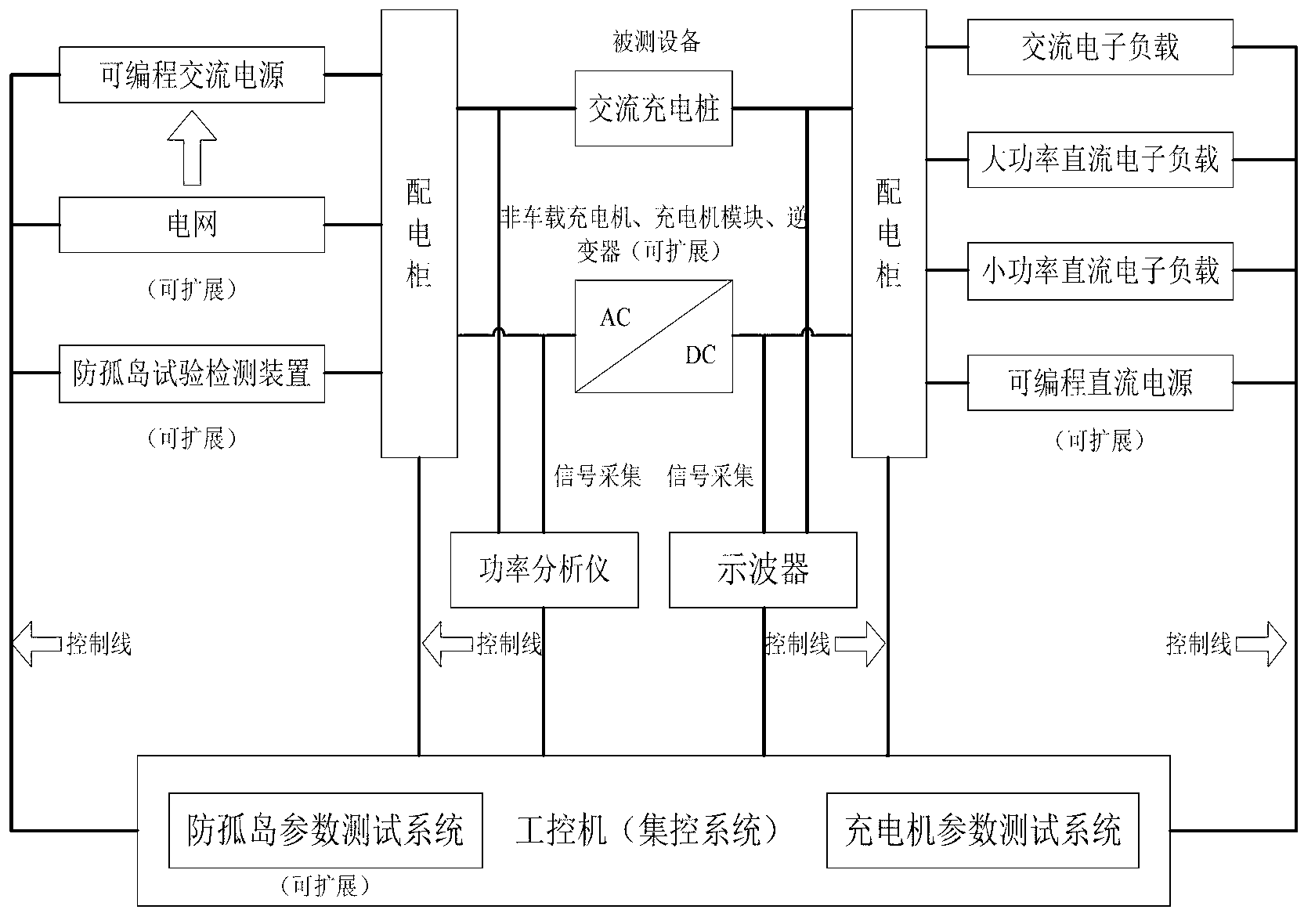

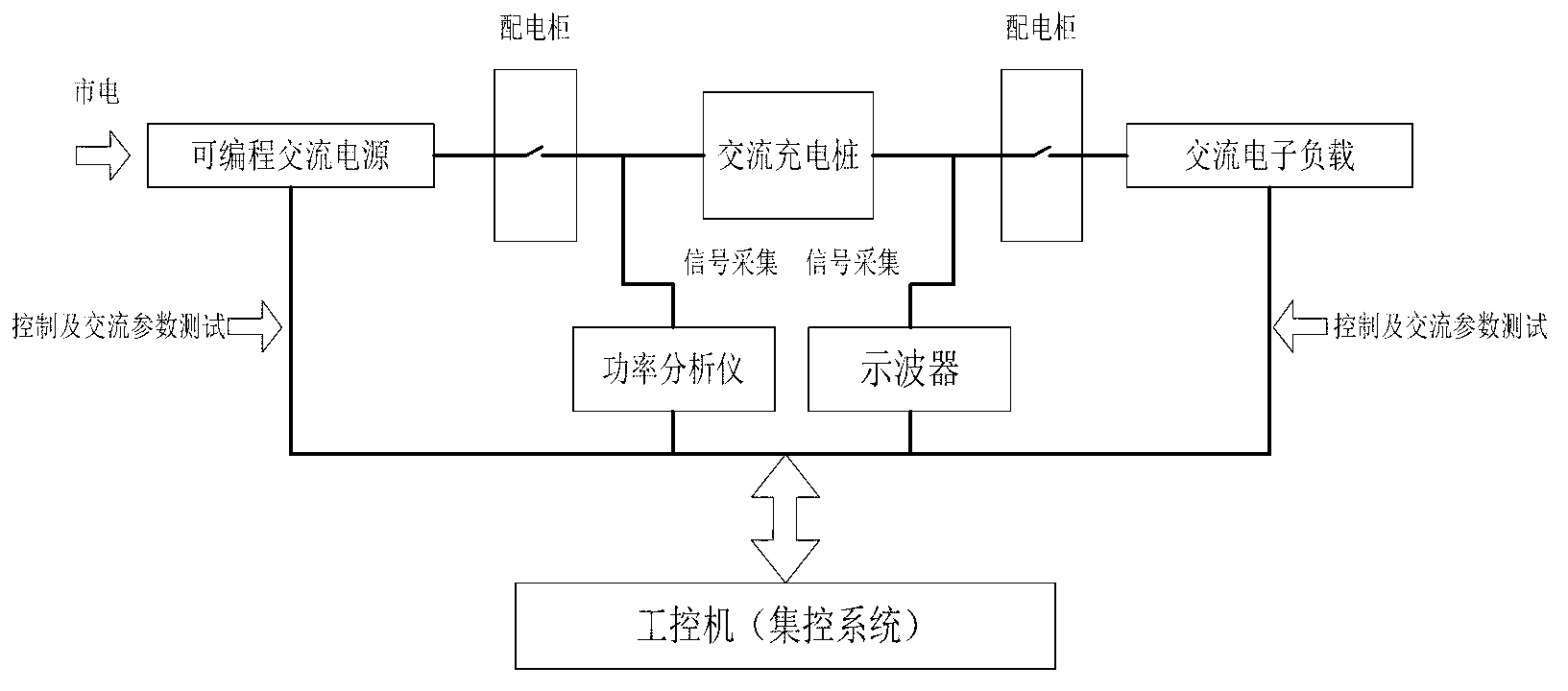

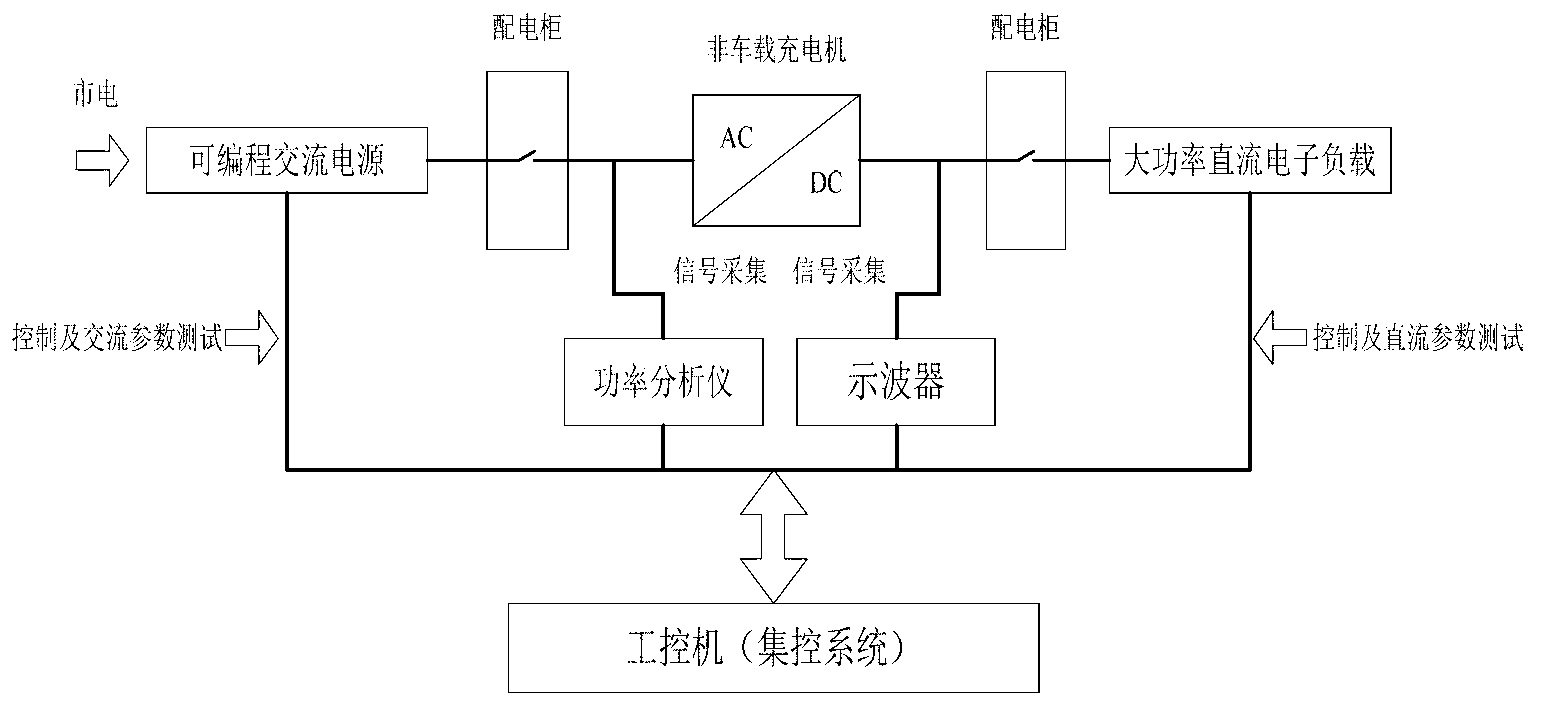

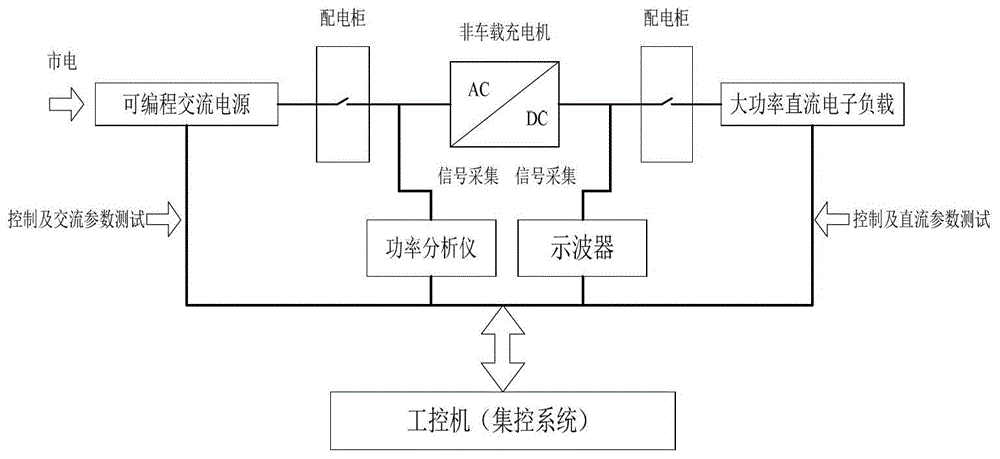

The inveniton relates to a method and system of automatic testing of electric automobile charging facilities. The testing method comprises the following steps that a device to be tested is connected to a detection platform; the device to be tested is detected according to a testing project; data detected by the detection platform are collected; collected data are analyzed; an analyzing result is output. Compared with the prior art, the method of automatic testing of the electric automobile charging facilities can conduct comprehensive testing on functional characteristics and performance indexes of an alternating current charging pile, a non-vehicle-mounted charger , a charger module and the like. Intelligentized centralized control is adopted, combination and batch execution of multiple testing projects can be achieved, a whole testing process can be executed by a centralized control platform automatically, and after testing is finished, a test report is generated automatically. A testing device can be used independently, and can be integrated to achieve systematic testing, and post-maintenance and post-calibration can be conducted conveniently. The method and the system of automatic testing of the electric automobile charging facilities can construct a fixed testing platform or a vehicle-mounted mobile testing platform.

Owner:STATE GRID CORP OF CHINA +1

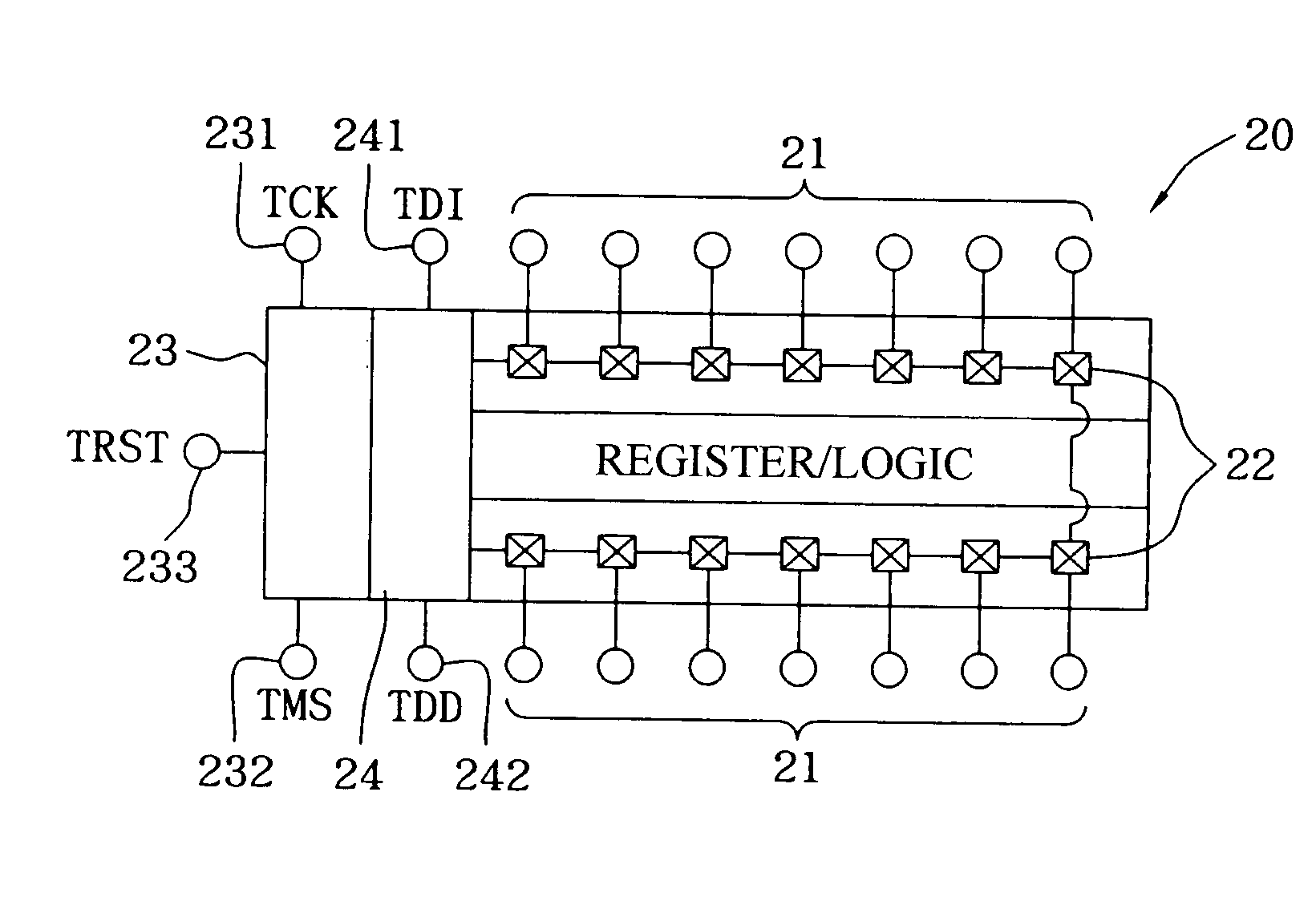

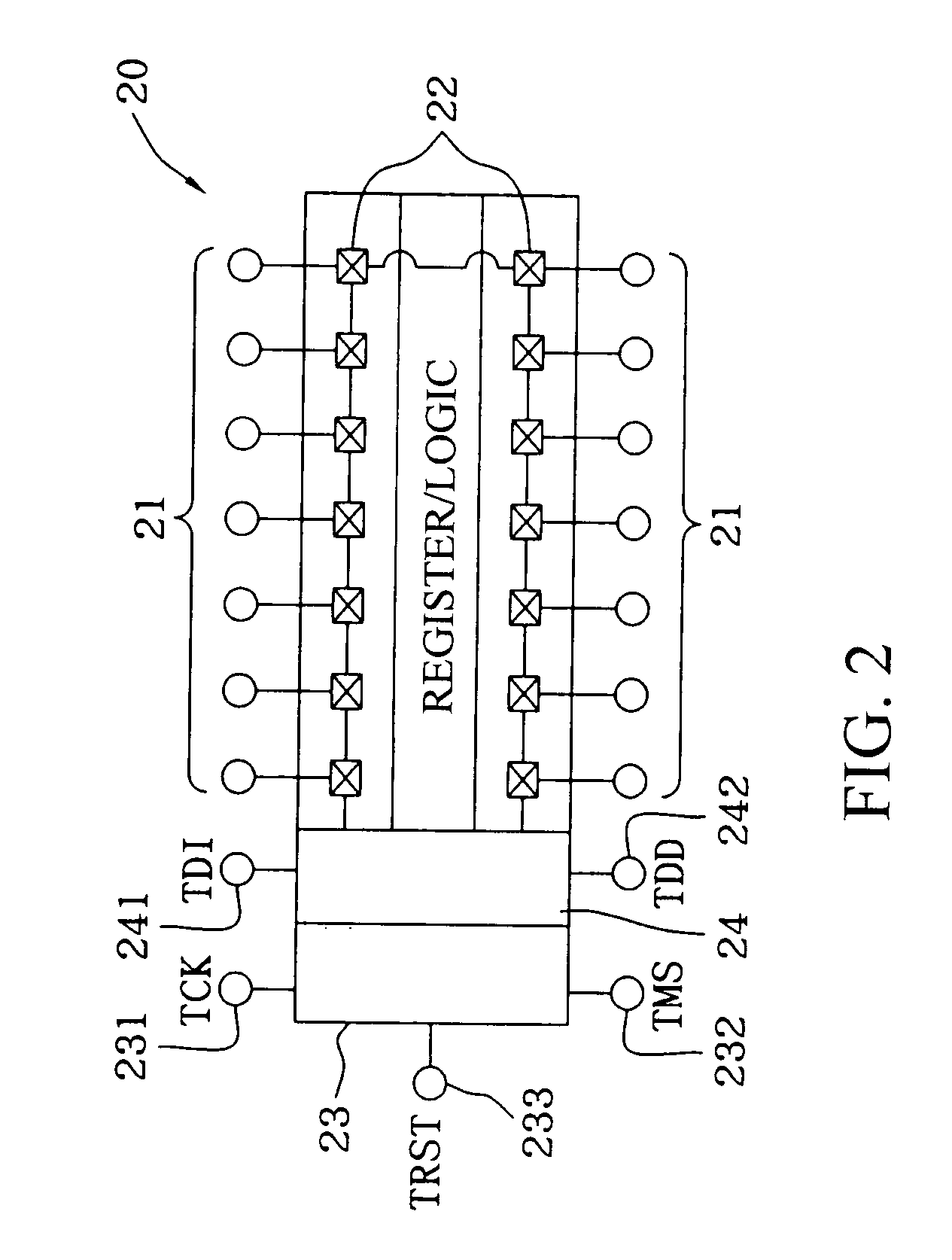

Circuit board having boundary scan self-testing function

A circuit board with a boundary scan self-testing function comprises a substrate, a plurality of devices under test and an active testing device. The active testing device mounted the substrate can conduct circuit testing on the plurality of devices under test, and self-testing is allowed without employing any external testing equipment. The testing data of the active testing device is transmitted through a predetermined test route on the circuit board. Each of the devices under test is completely tested of all designated functions in either series connection or parallel connection with each other. The testing can help find out whether the devices have any defects.

Owner:LEADTEK

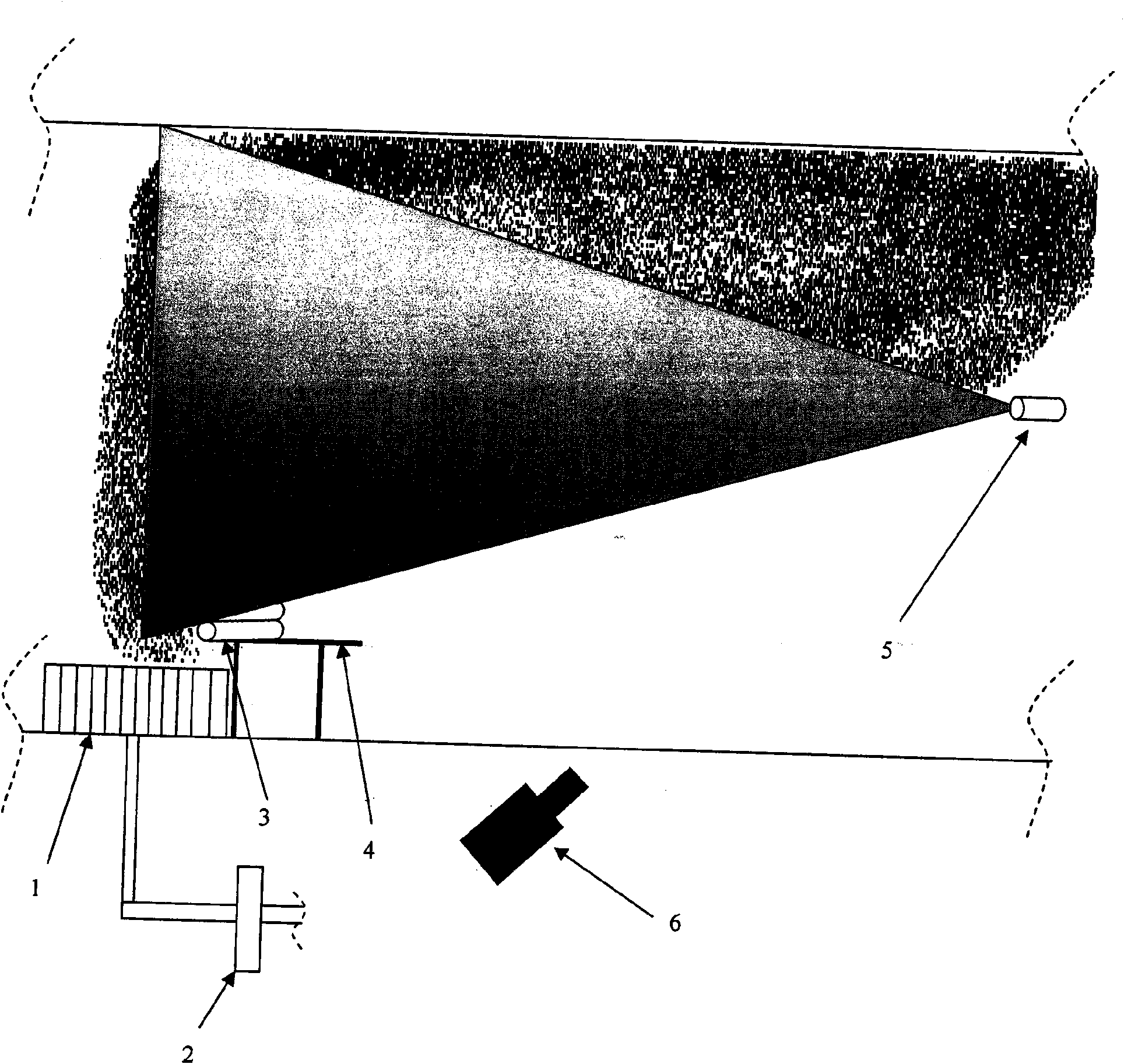

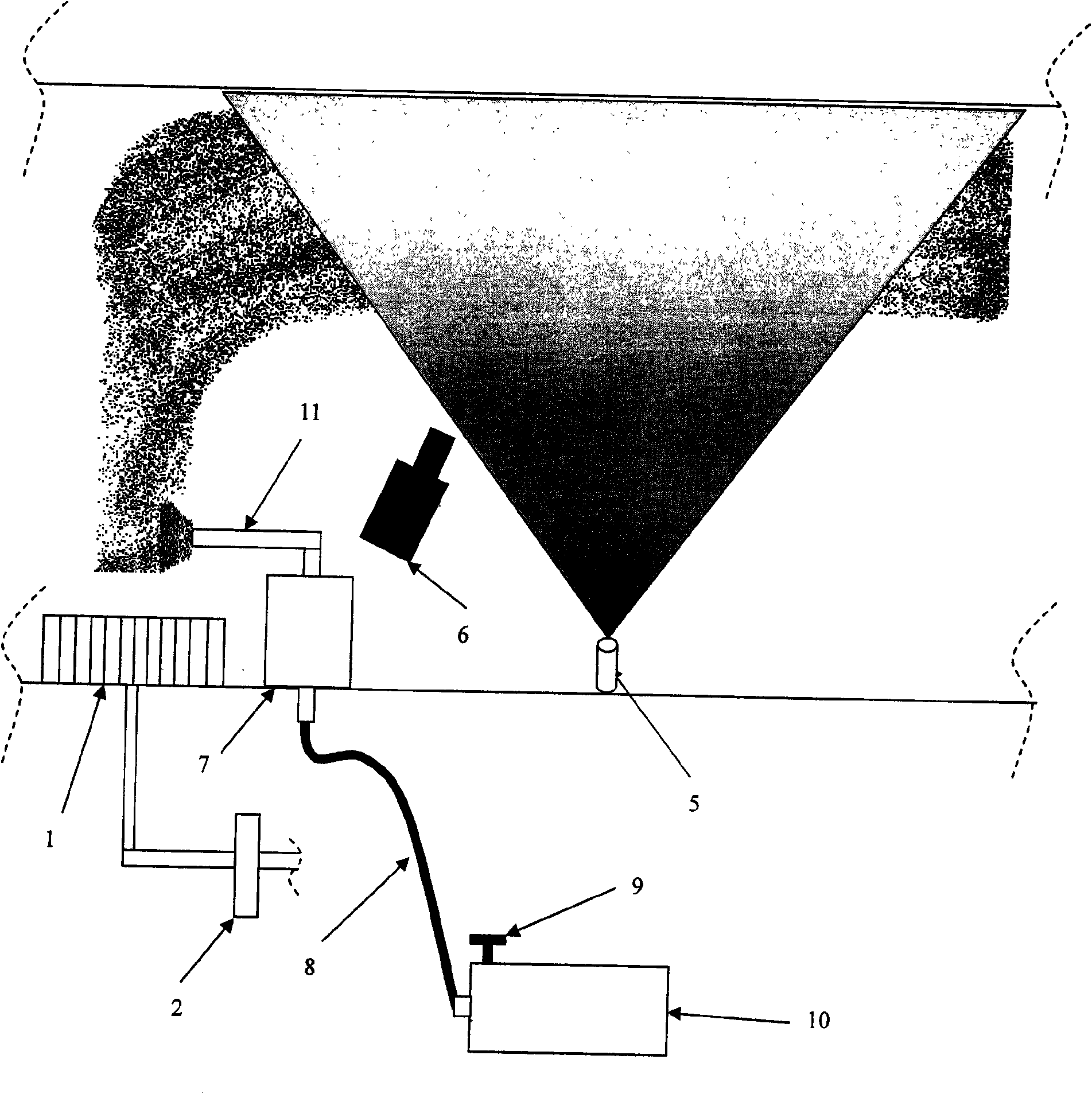

Fire smoke flow field tracer method

InactiveCN101639398ANo pollution in the processPower controllableHydrodynamic testingMaterial analysis by optical meansFire testFlue gas

The invention provides a fire smoke flow field tracer method which comprises a fire source analog system, a laser sheet optical system, an image pickup system, a smoke particle analog method and a tracer grain adding method; wherein the fire source analog system adopts a propane gas burner with controllable gas flow rate; smoke particles generated by burning sandalwood are adopted to simulate firesmoke particles; the grain diameter of the tracer grain is 1-5mu m of boron nitride grain; the boron nitride grains are evenly and stably transmitted into a flue gas layer by an air compressor; the method can be widely applied to small-scale and full-scale tests of fire, so as to lead the process of fire test to be safe, controllable and environment-friendly; by adopting the method, the key parameters such as the thickness, the form, the flow field structure and the like of the fire flue gas layer can be obtained, thus having important significance for guiding fire smoke control.

Owner:UNIV OF SCI & TECH OF CHINA

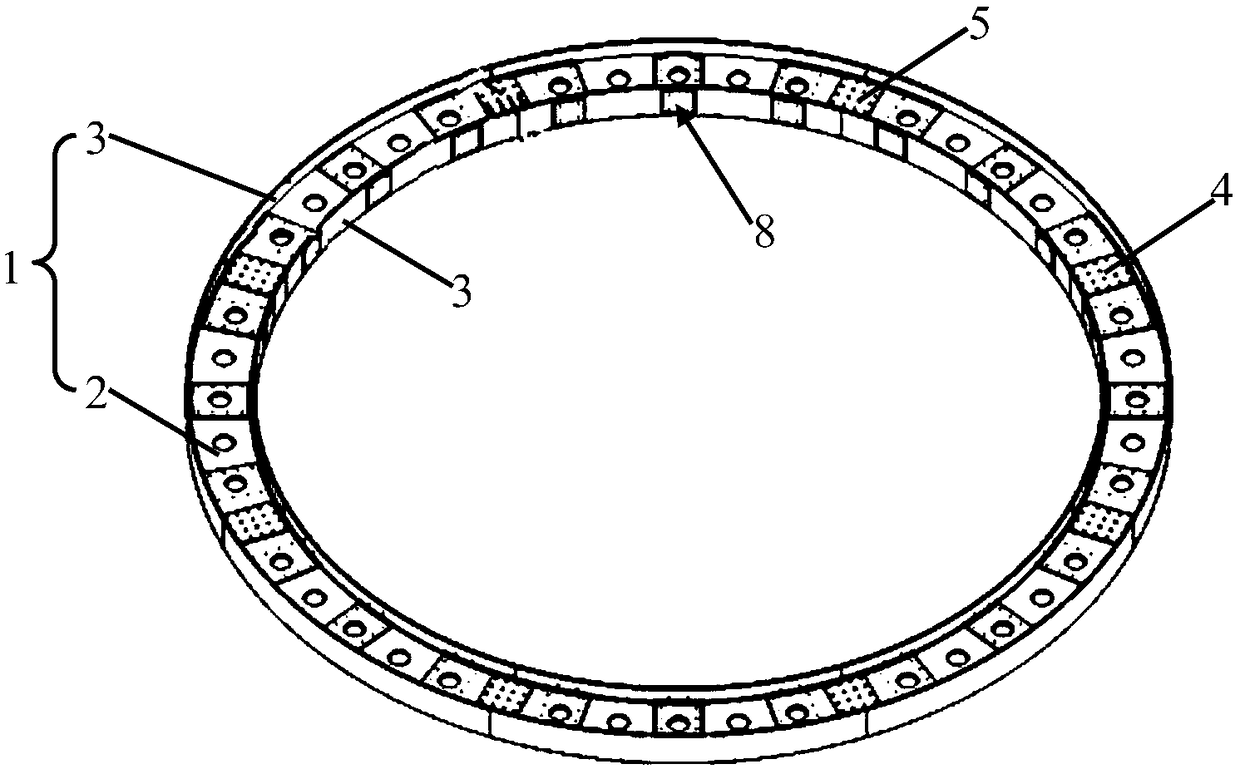

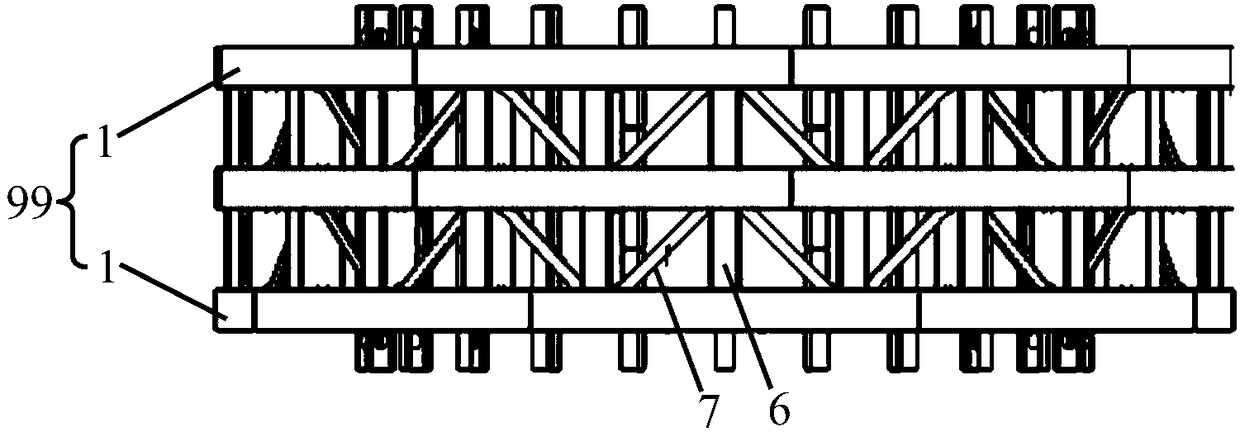

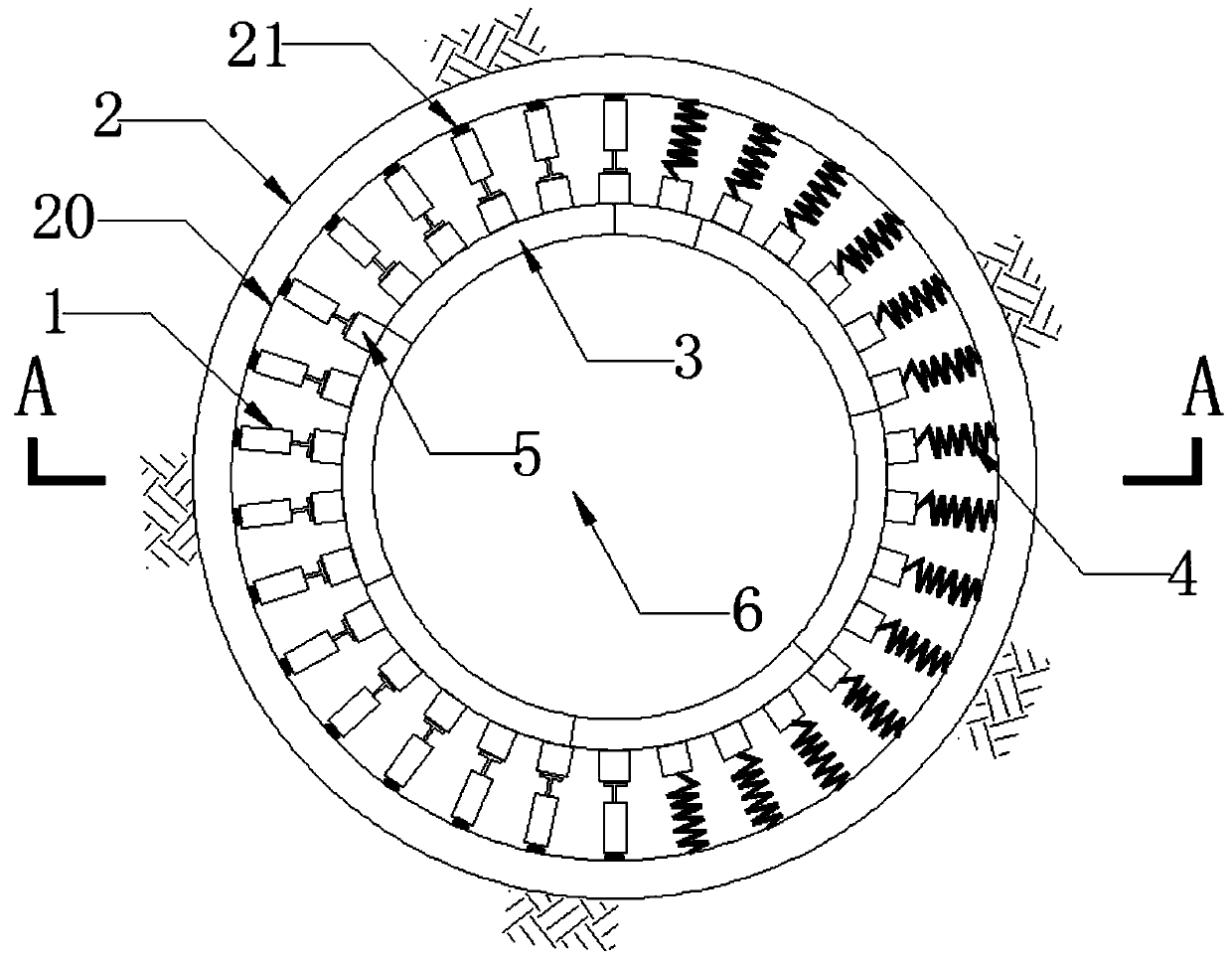

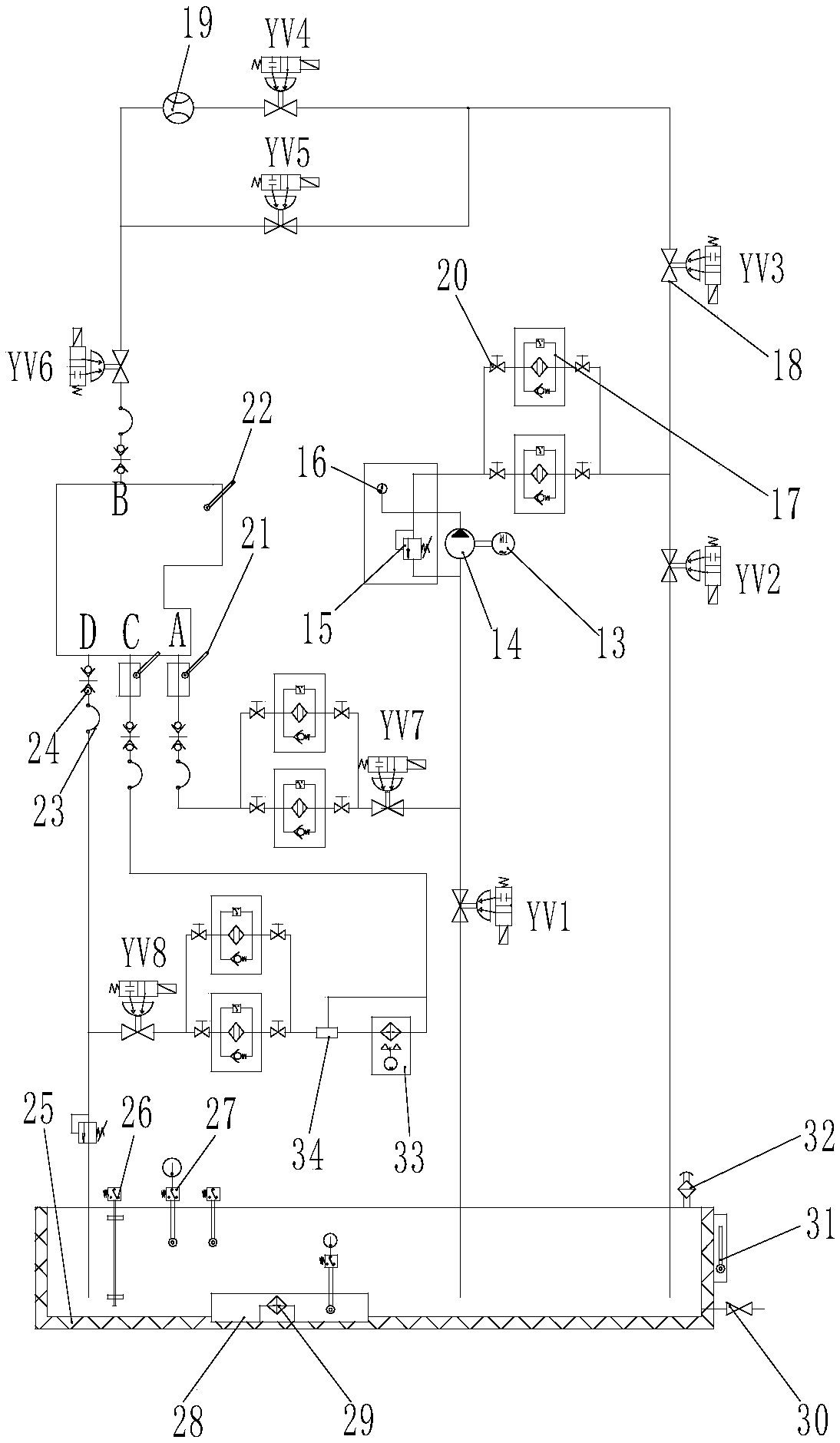

Shield segment mechanical simulation test device

PendingCN108344637AStay flexibleMaintain durabilityMaterial strength using tensile/compressive forcesEngineeringFull scale test

The invention provides a shield segment mechanical simulation test device. The shield segment mechanical simulation test device comprises a main body reaction frame, a radial direction loading mechanism, and an expanding beam; the radial direction loading mechanism comprises an installation end and an extension end; the installation end is adjustably arranged on the internal wall of the main bodyreaction frame, so that angular deflection fine adjustment of the radial direction loading mechanism in a same radial direction plane towards a radial direction can be realized; the expanding beam isdesigned to telescope or extend toward the center of the main body reaction frame with relative to the installation end in an adjustable manner; the expanding beam is arranged along the axis directionof the shield segment, and is detachably arranged on the extension end; the radial direction loading mechanism is used for loading the expanding beam with radial direction loading, and then the radial direction loading is transferred onto the external wall of the shield segment through the expanding beam. According to the shield segment mechanical simulation test device, multifunctional loading and precision guiding are adopted for stimulation of mechanical behaviors of the shield segment, so that sheld segment tunnel full-scale test quality and efficiency are increased.

Owner:TONGJI UNIV +1

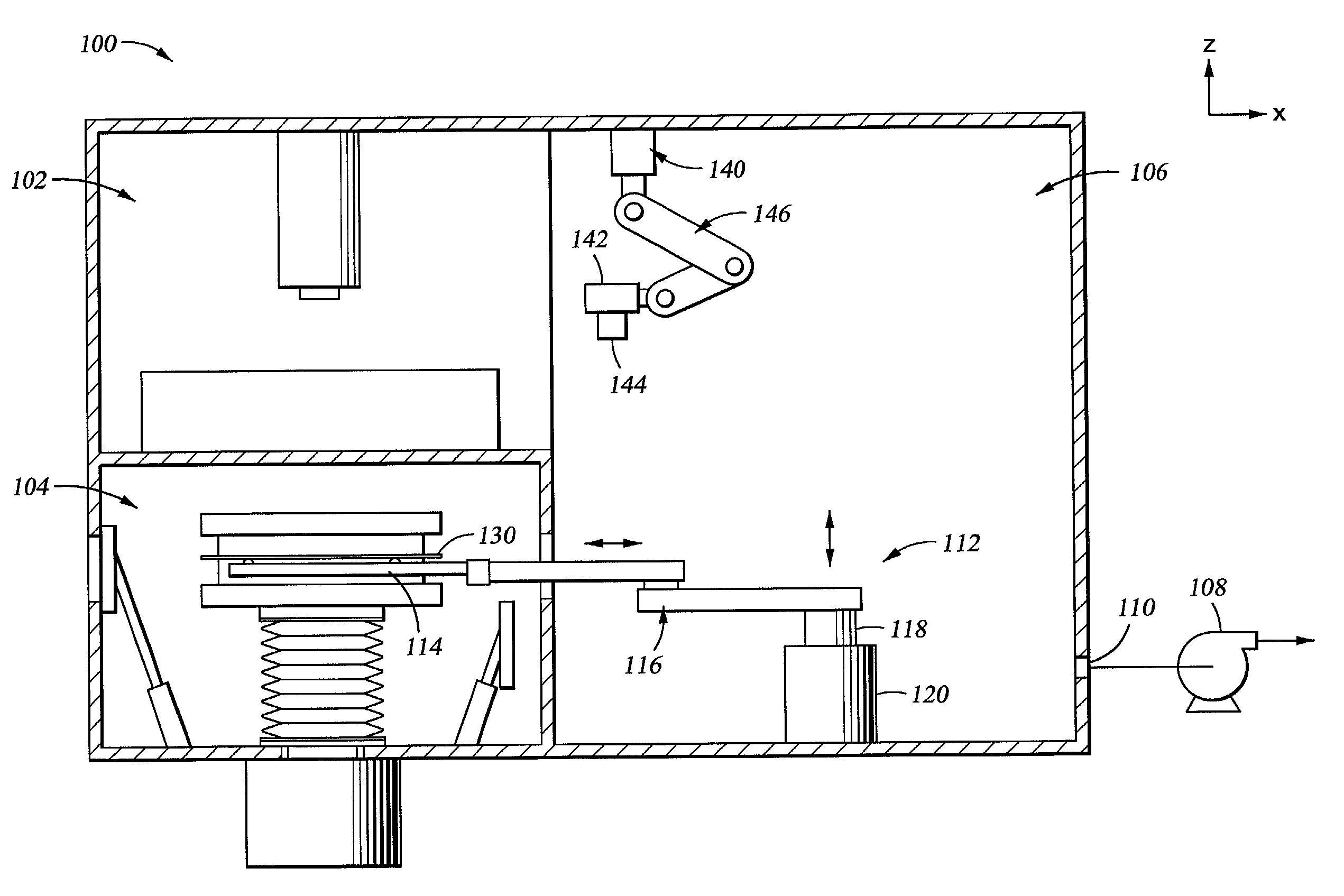

Large substrate test system

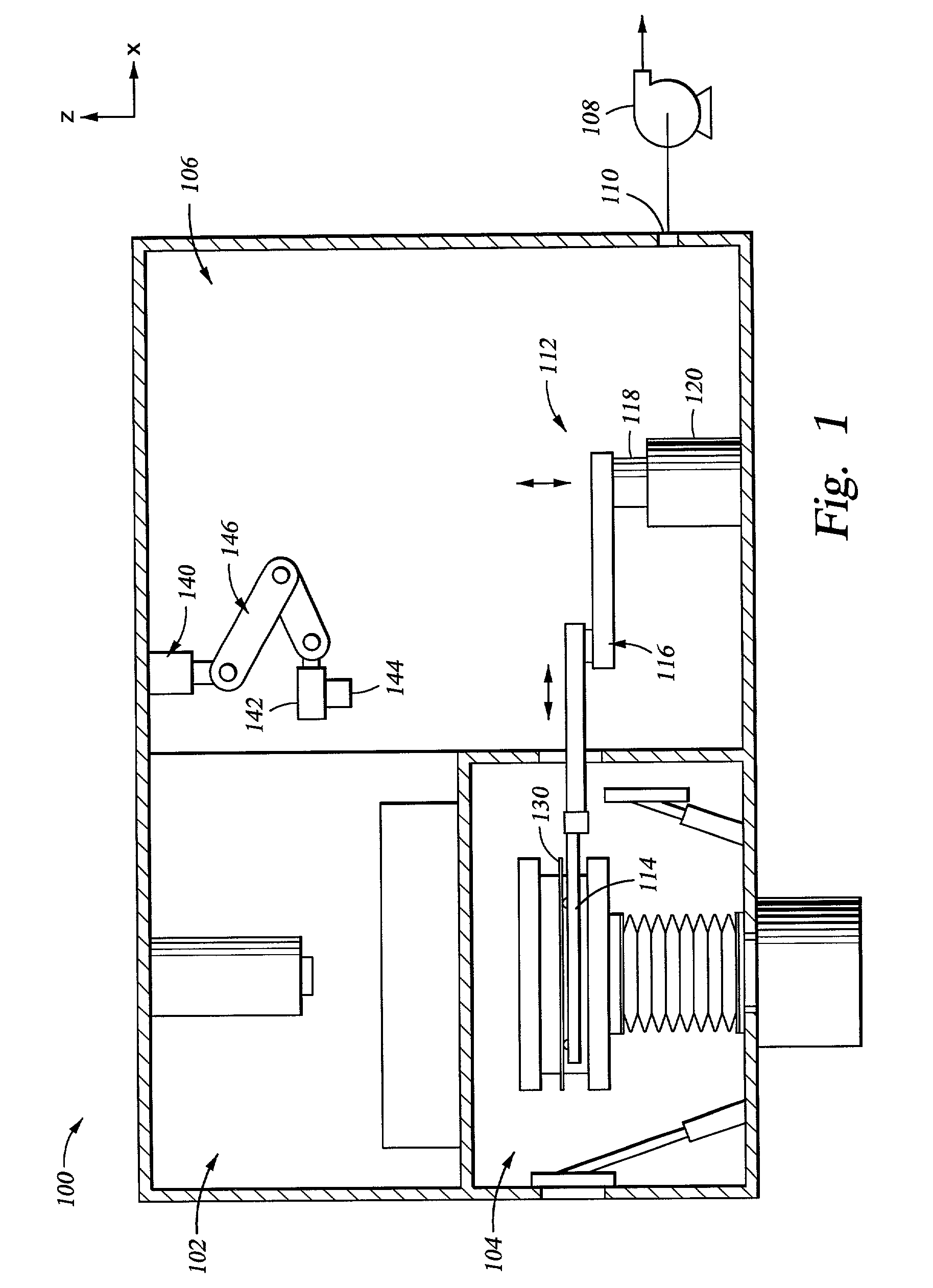

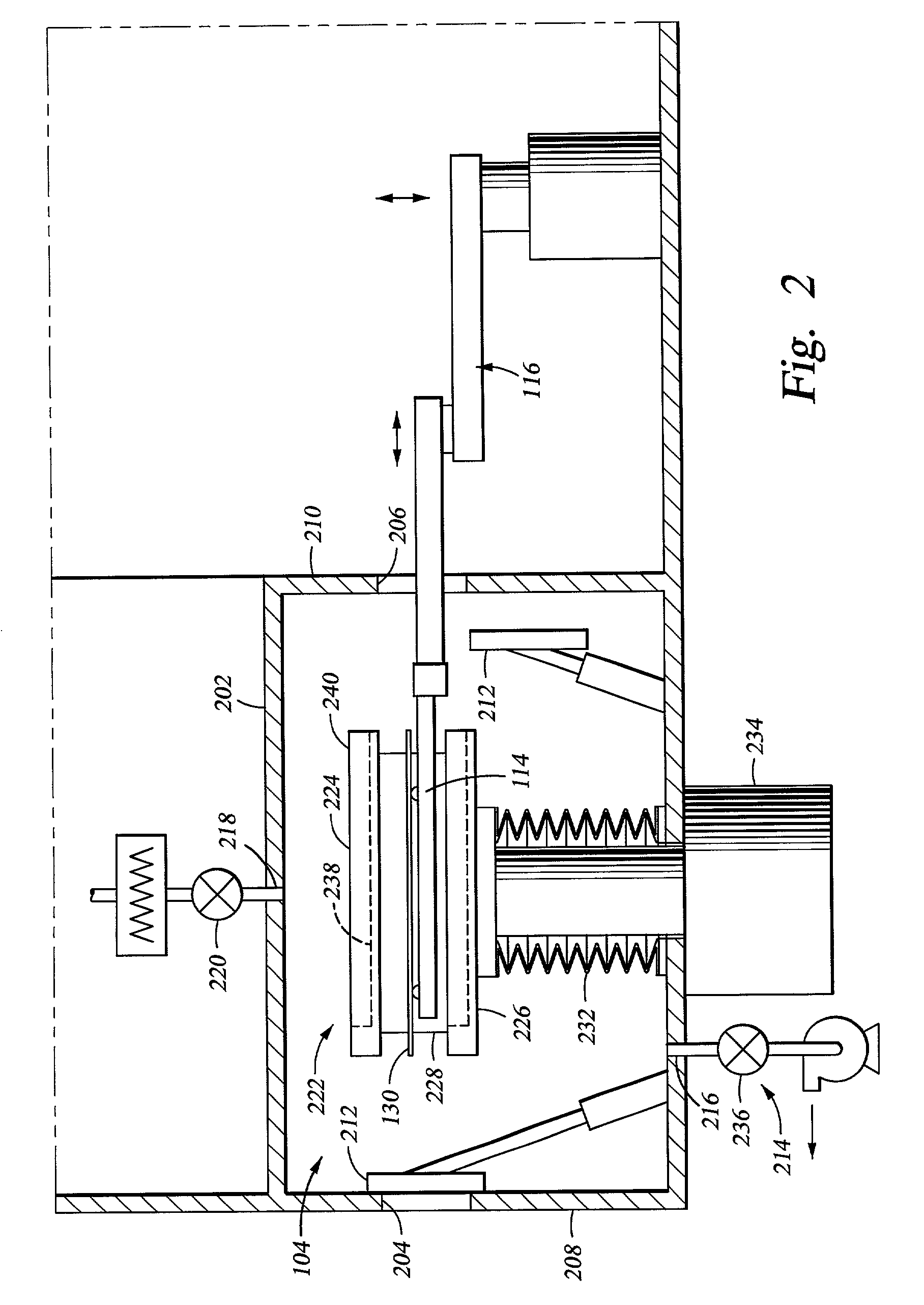

InactiveUS7129694B2Semiconductor/solid-state device testing/measurementElectric discharge tubesRange of motionTest station

A system and method for testing substrates is generally provided. In one embodiment, a test system for testing a substrate includes a load lock chamber, a transfer chamber and a test station. The load lock chamber and the test station are disposed on top of one another and coupled to the transfer chamber. The transfer chamber includes a robot adapted to transfer a substrate between the load lock chamber, which is at a first elevation, and the test station, which is at a second elevation. In another embodiment, a test station is provided having a turntable adapted to rotate the substrate. The turntable enables the range of motion required to test the substrate to be substantially reduced while facilitating full test and / or inspection of the substrate.

Owner:APPLIED MATERIALS INC

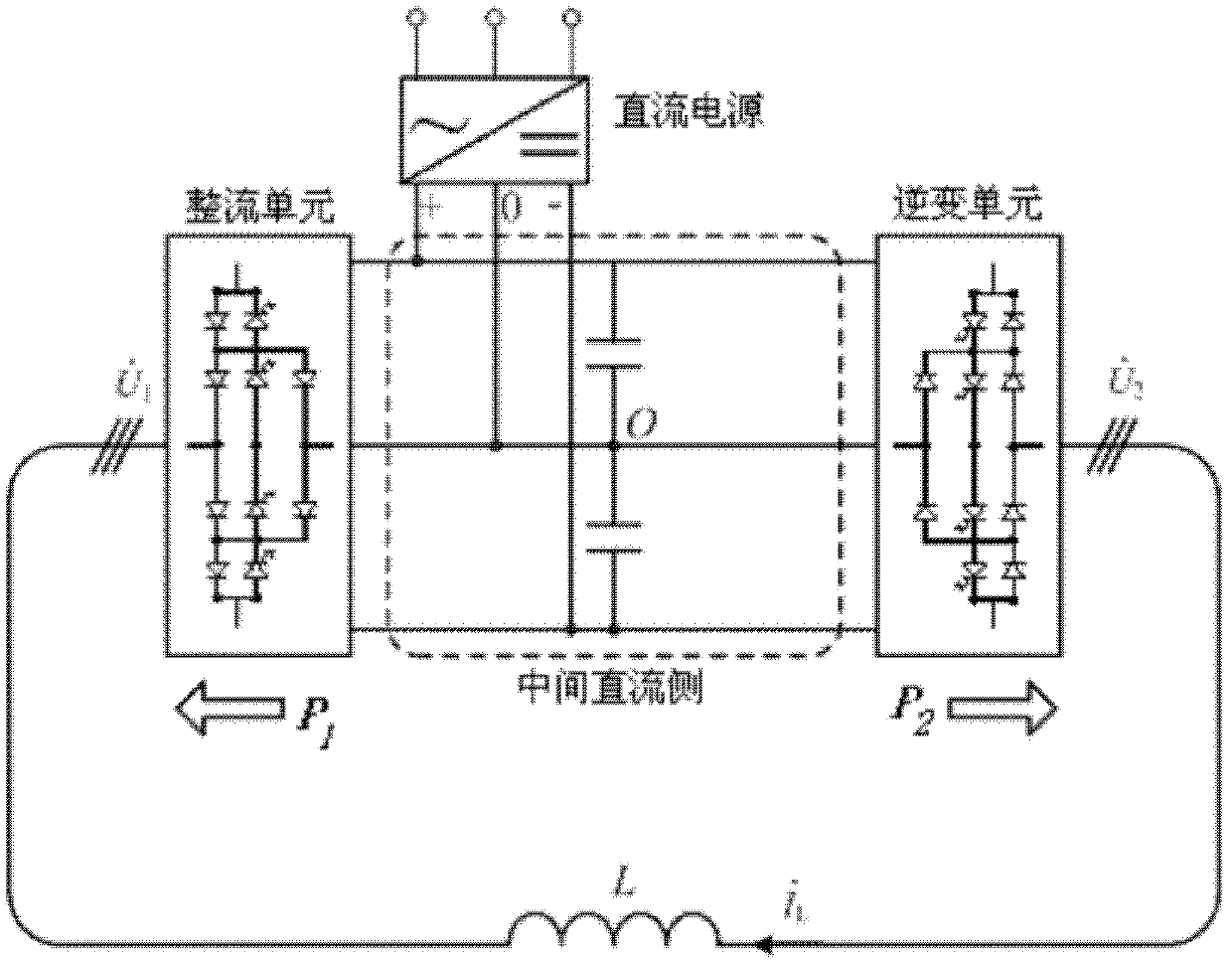

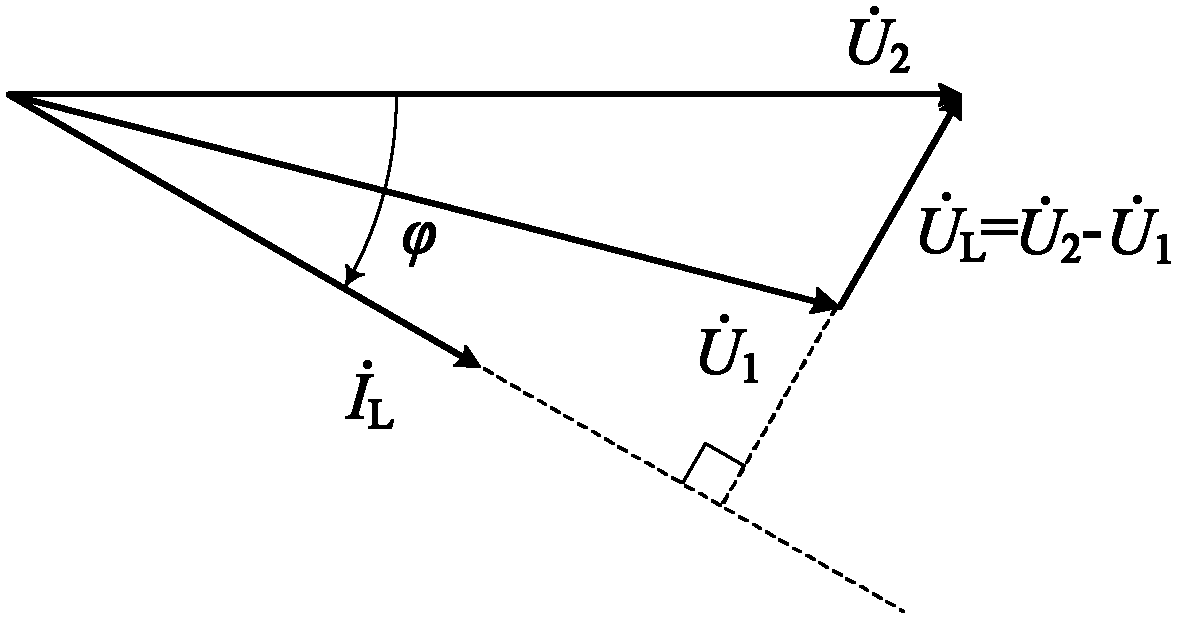

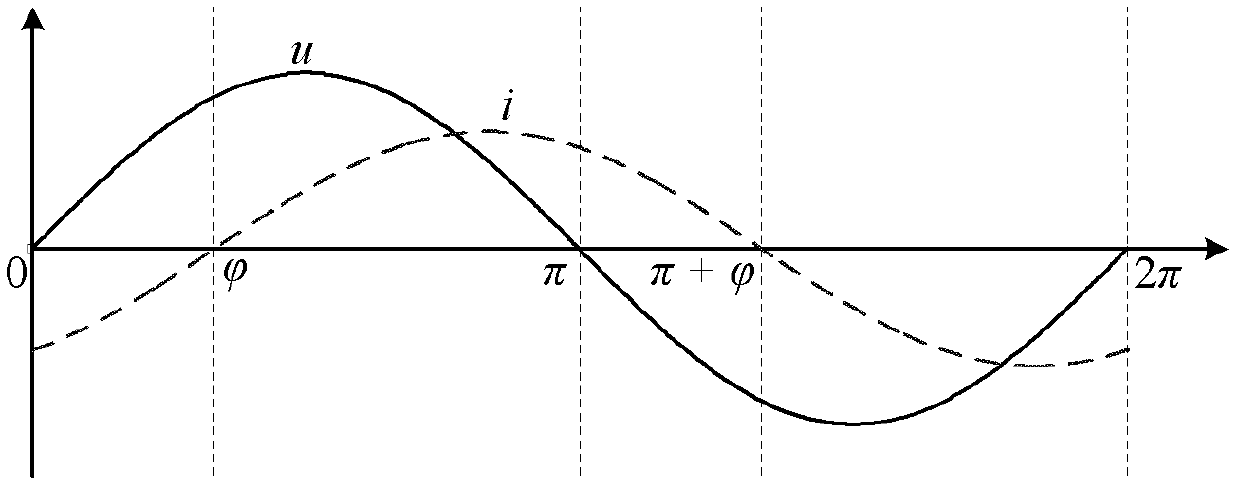

High-power three-level frequency converter temperature rise and loss testing method employing active front end

ActiveCN102508072ARealize the function of load testReduce capacityElectrical testingFrequency changerThree level

The invention relates to a high-power three-level converter temperature rise and loss testing method employing an active front end. The method is characterized by comprising the following steps of: (1) connecting a low-capacity reactor between a rectifying unit and an inverter unit of a frequency converter, and connecting a low-capacity direct-current power supply to a middle direct-current side of the frequency converter, and (2) setting the rectifying unit to operate in an inverter manner, setting an output voltage reference value of the rectifying unit and the output voltage reference value of the inverter unit at fixed values, adjusting the current which flows through the reactor, and simulating different work conditions and comprehensively testing the loss and temperature rise of the frequency converter under different work conditions by adjusting the magnitude of the output power and the power factor of the inverter unit so as to accurately estimate the output of the device. According to the invention, high-powder three-level frequency converter temperature rise and loss testing functions can be achieved by only one low-capacity reactor and one external low-capacity direct-current power supply. The method has the advantages of simple structure, accurate result, fewer used auxiliary apparatuses, easy realization and the like.

Owner:TIANJIN RES INST OF ELECTRIC SCI +1

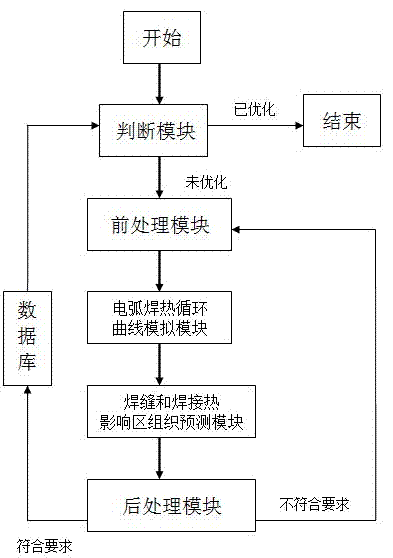

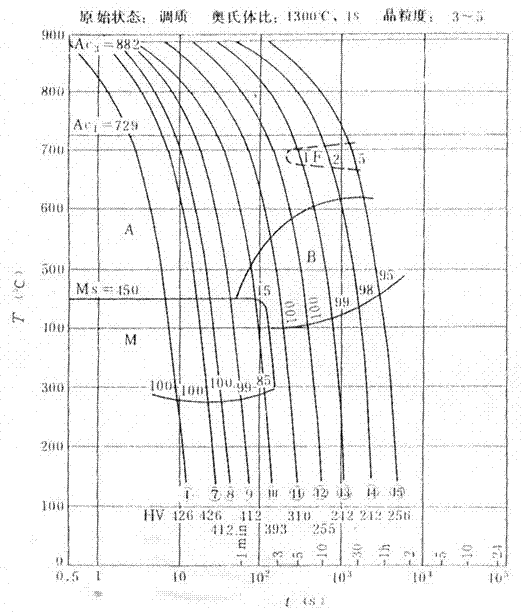

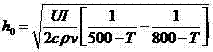

Method and device for automatically optimizing electric-arc welding process parameters

The invention discloses a method and device for automatically optimizing electric-arc welding process parameters. The method comprises the following steps of: simulating welding heat-cycle curves of electric arc welding under different process parameters by utilizing a computer technology, carrying out superimposition with a continuous cooling structural transformation diagram of a welding base material, and predicating corresponding welding seams and the structure of a heat-affected zone till the requirement is met, so that the optimization of the electric-arc welding process parameters is automatically realized. Therefore, the method and device disclosed by the invention has the advantage that the full-scale testing times for obtaining excellent welding seam structures is greatly reduced.

Owner:珠海奥邦焊接科技有限公司

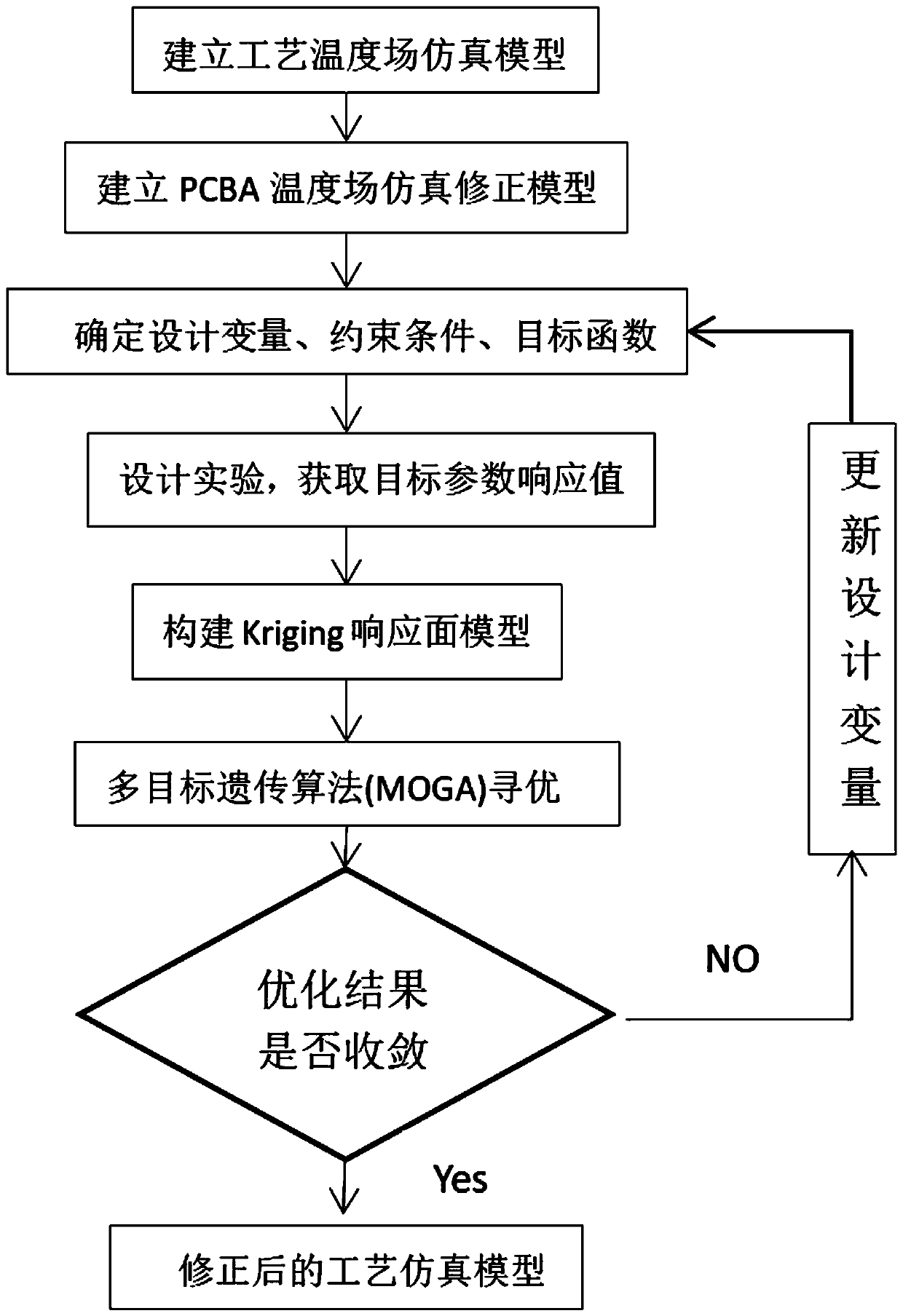

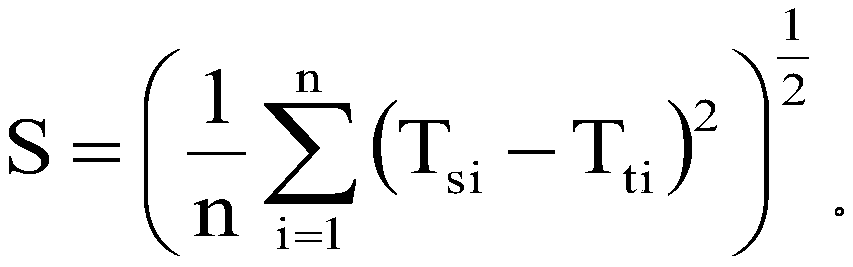

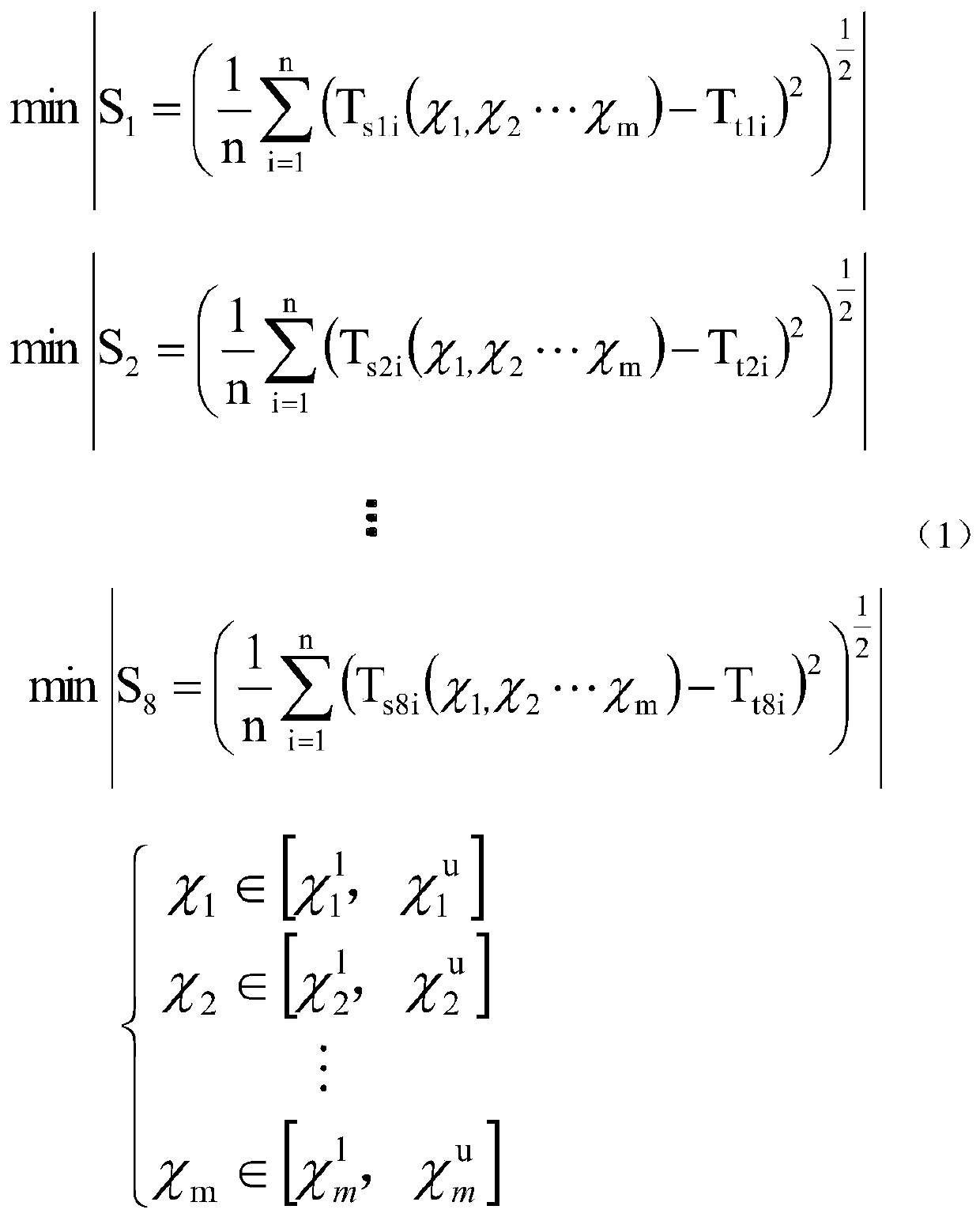

Reflow welding process simulation model correction method based on measured temperature data

ActiveCN110866358AFast correctionImprove correction accuracyDesign optimisation/simulationThermodynamicsTemperature curve

The invention discloses a reflow welding process simulation model correction method based on measured temperature data. By analyzing the standard deviation between the actually measured temperature curve data and the correspondingly simulated temperature curve data, a numerical simulation correction model which takes the minimization of the standard deviation between the node temperatures corresponding to the actually measured curve and the simulation curve as an optimization target and takes the temperature of the temperature zone and the convective heat transfer coefficient as optimization variables is established. The model is optimized by adopting a response surface method and a multi-objective genetic optimization algorithm method, so that the result of the numerical simulation modelis consistent with the actually measured temperature, the corrected numerical simulation model is obtained, and the accuracy of subsequent simulation prediction can be improved through feedback adjustment of one-time physical test. According to the method, the reflow welding process simulation model is corrected by a method of combining finite element simulation and tests, so that the simulation efficiency and precision are effectively improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

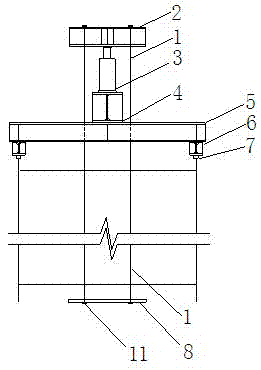

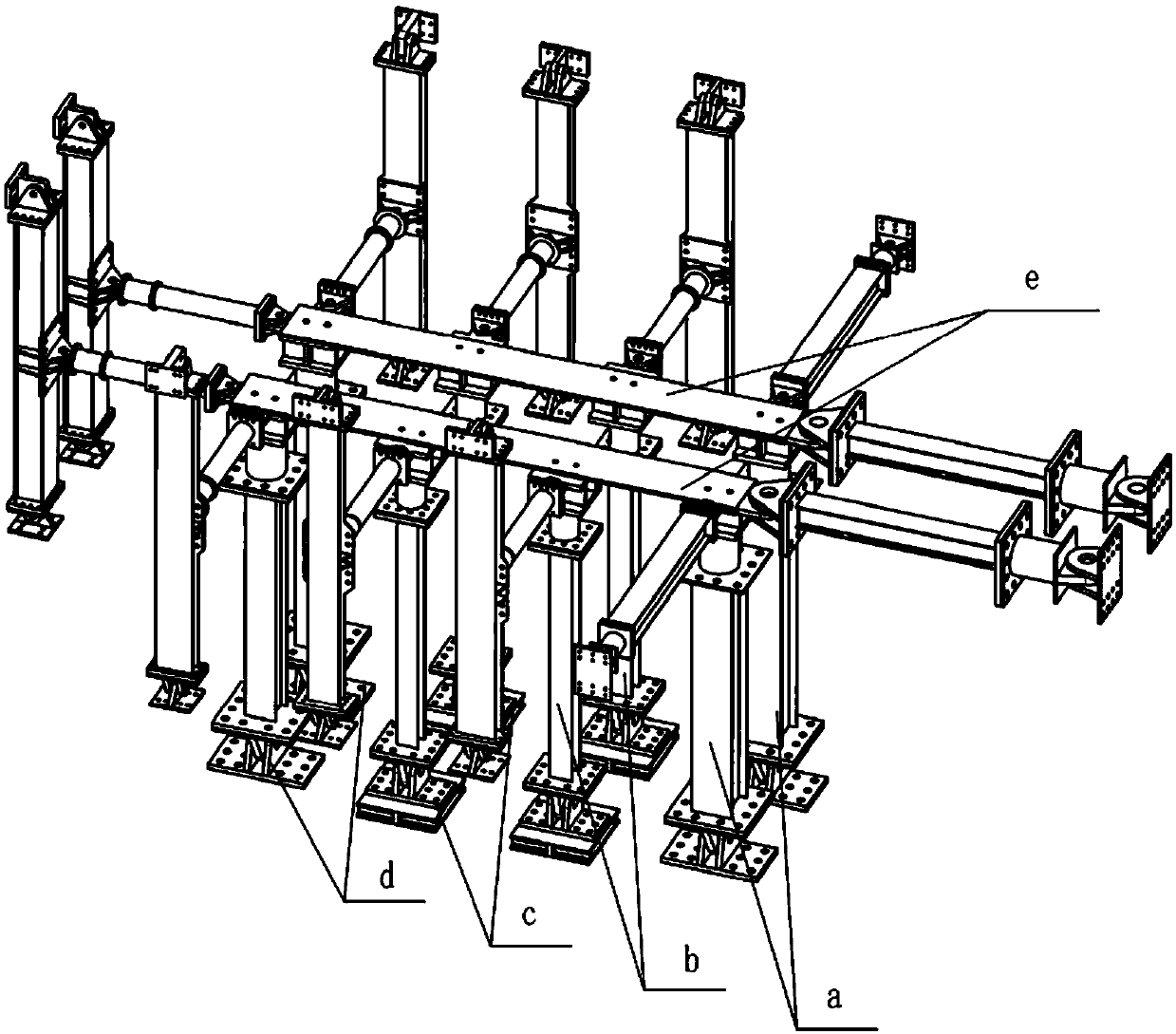

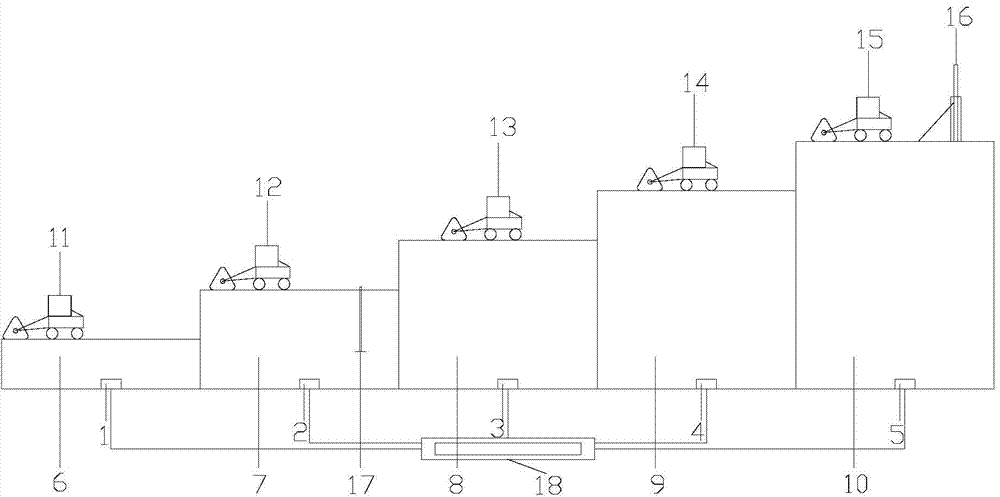

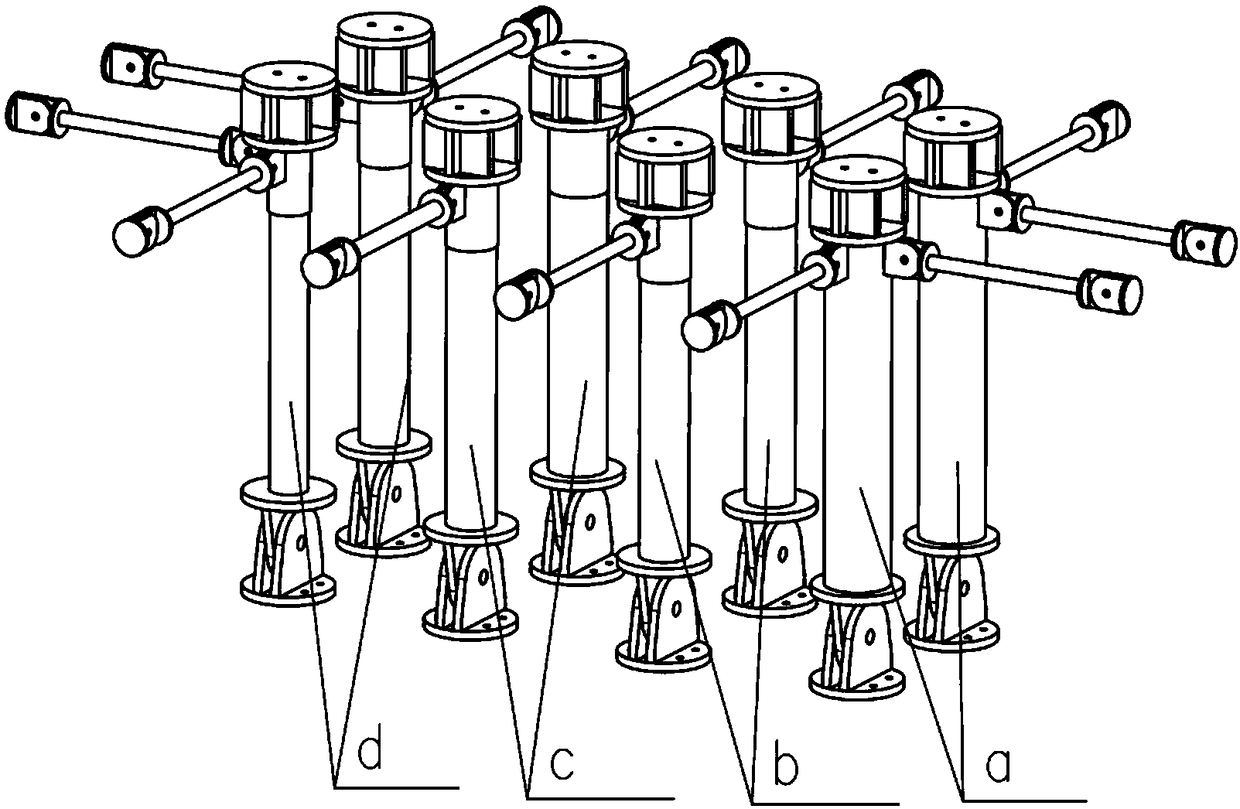

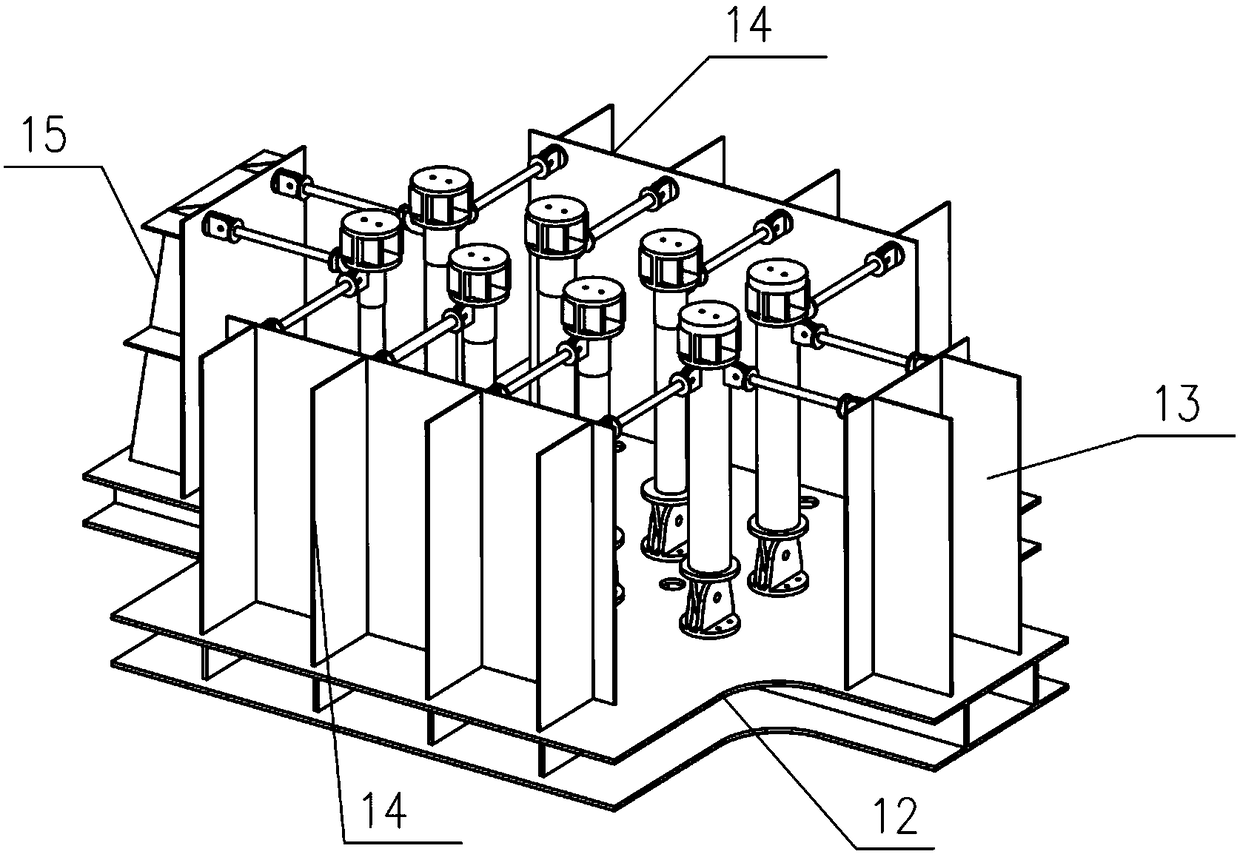

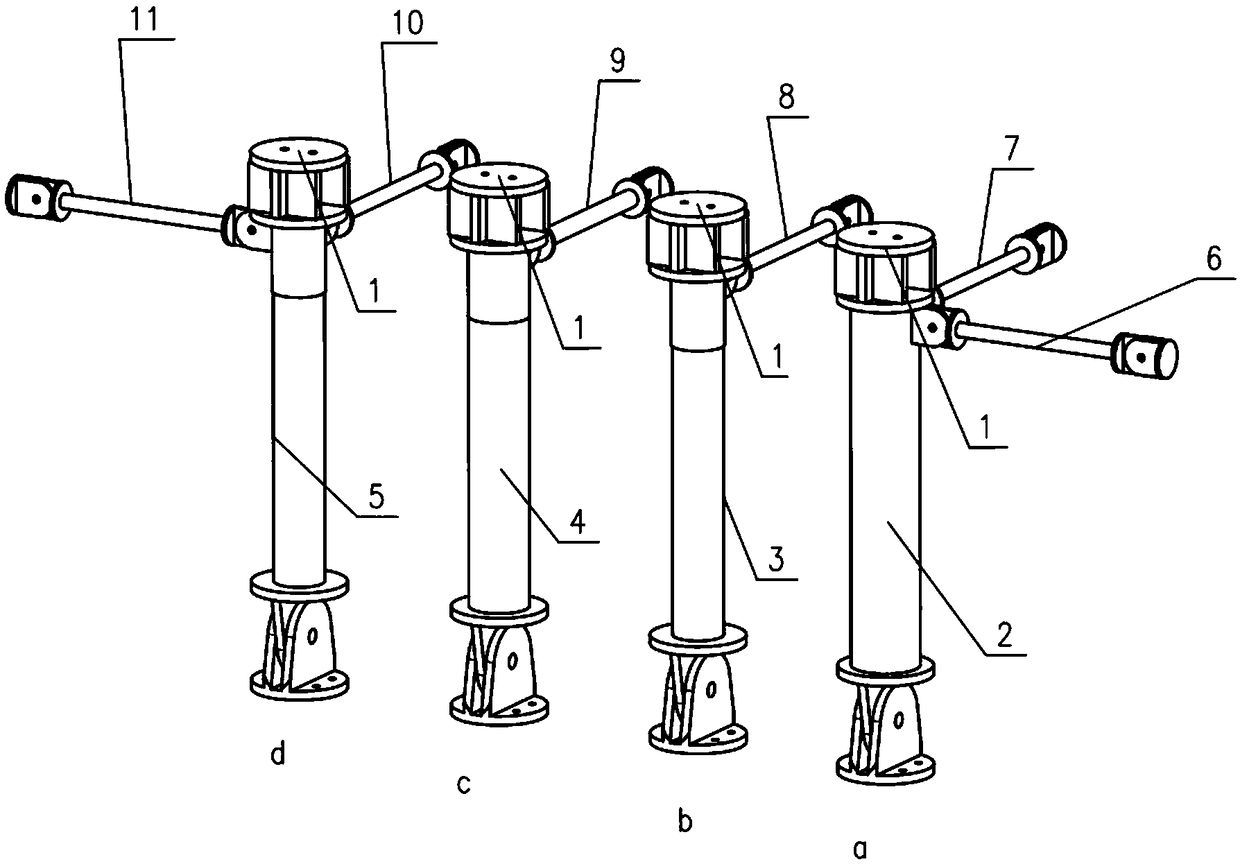

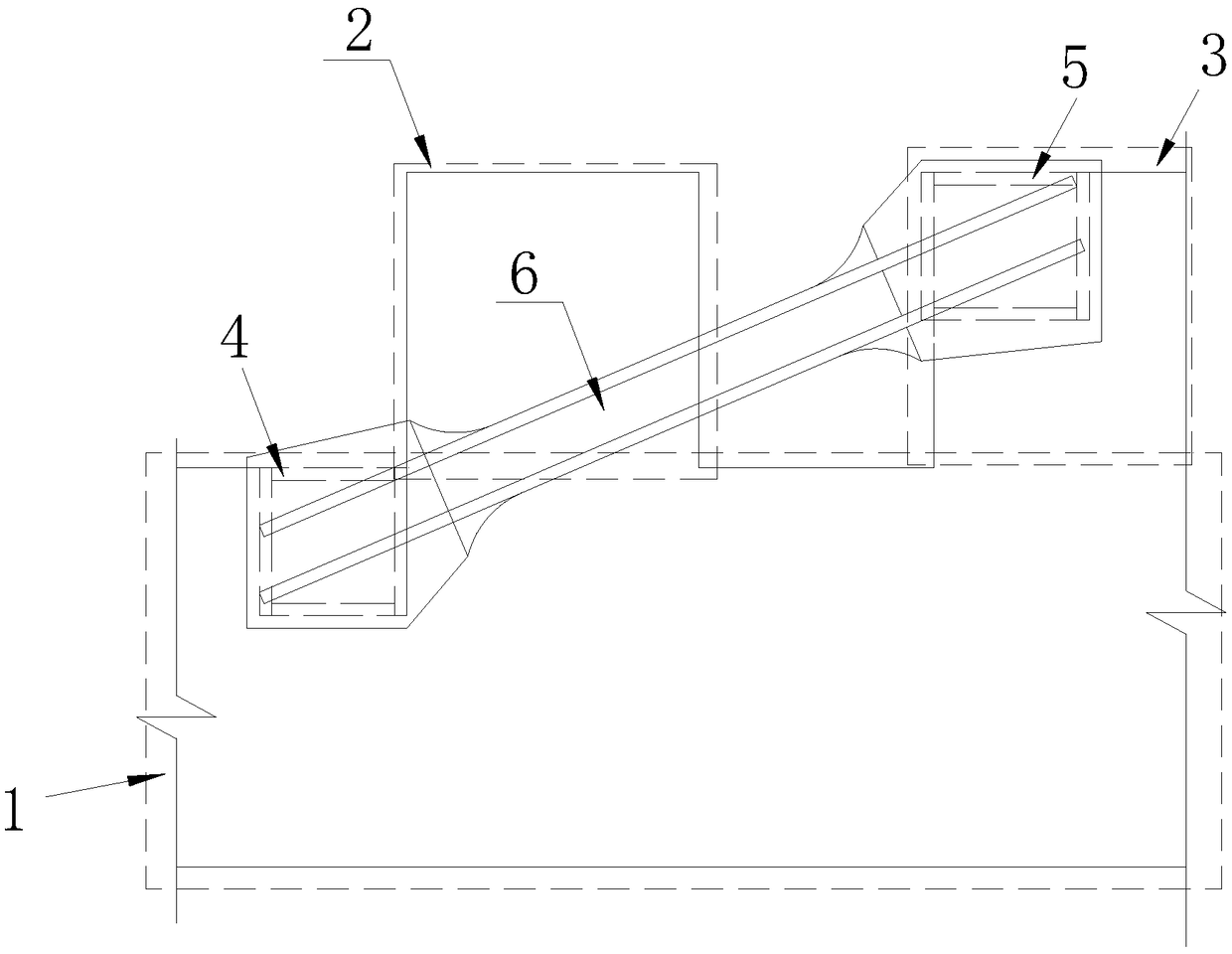

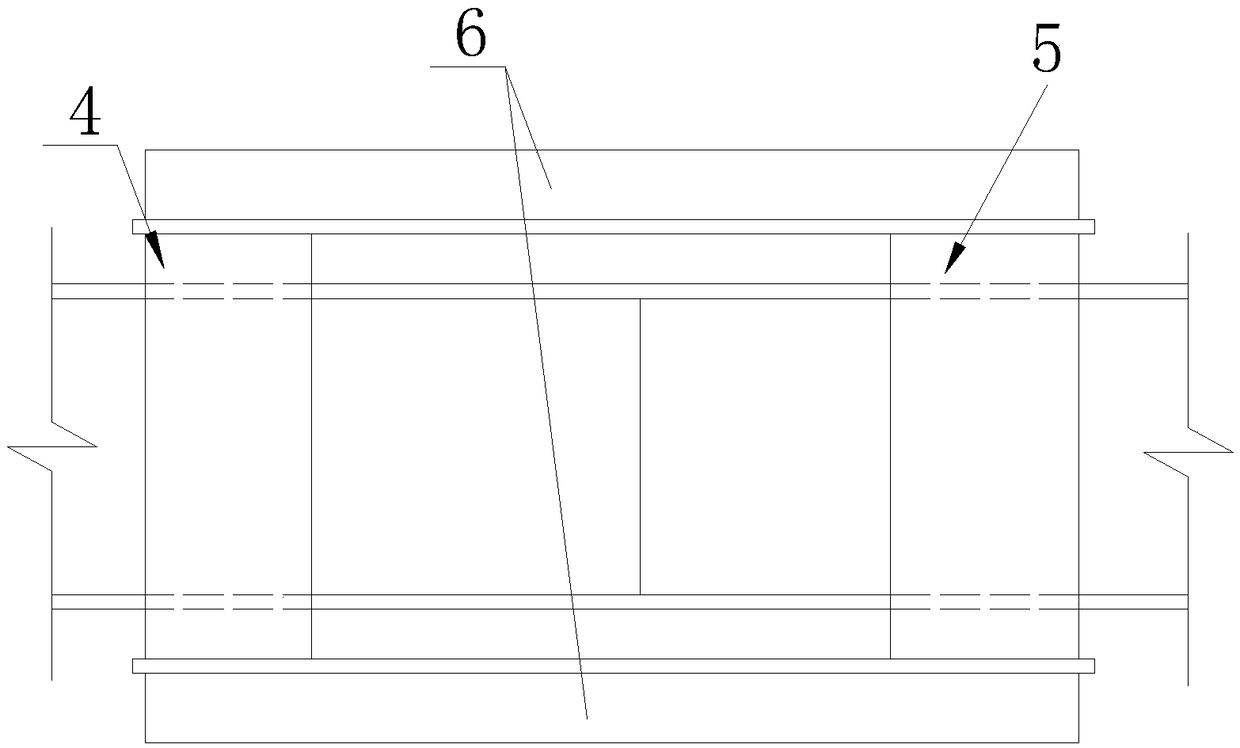

Loading device for high formwork support system full-scale test

InactiveCN102252911ASimple structureLow costMaterial strength using tensile/compressive forcesStructural/machines measurementSupporting systemEngineering

The invention discloses a loading device for a high formwork support system full-scale test. The device mainly comprises a force transmission rebar, a counterforce beam, a jack, a tertiary distributive girder, secondary distributive girders and first distributive girders. An upper end of the force transmission rebar is connected with the counterforce beam, and a lower end of the transmission rebar is connected with a connection board through bolts fixed in a ground groove; the jack is arranged under the counterforce beam, and the tertiary distributive girder is arranged under the jack; two ends of the tertiary distributive girder are equipped with the secondary distributive girders, wherein a length direction of the tertiary distributive girder is perpendicular to length directions of thesecondary distributive girders. Similarly, two ends of each secondary distributive girder are equipped with the first distributive girders, wherein length directions of the secondary distributive girders are perpendicular to length directions of the first distributive girders; each top of test vertical rods is disposed inside a sleeve, and each vertical rod is applied with load through the first distributive girders. The loading device of the present invention can load accurately and easily control loading steps and loads, and is convenient for step-by-step loading in the high formwork support system full-scale test.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

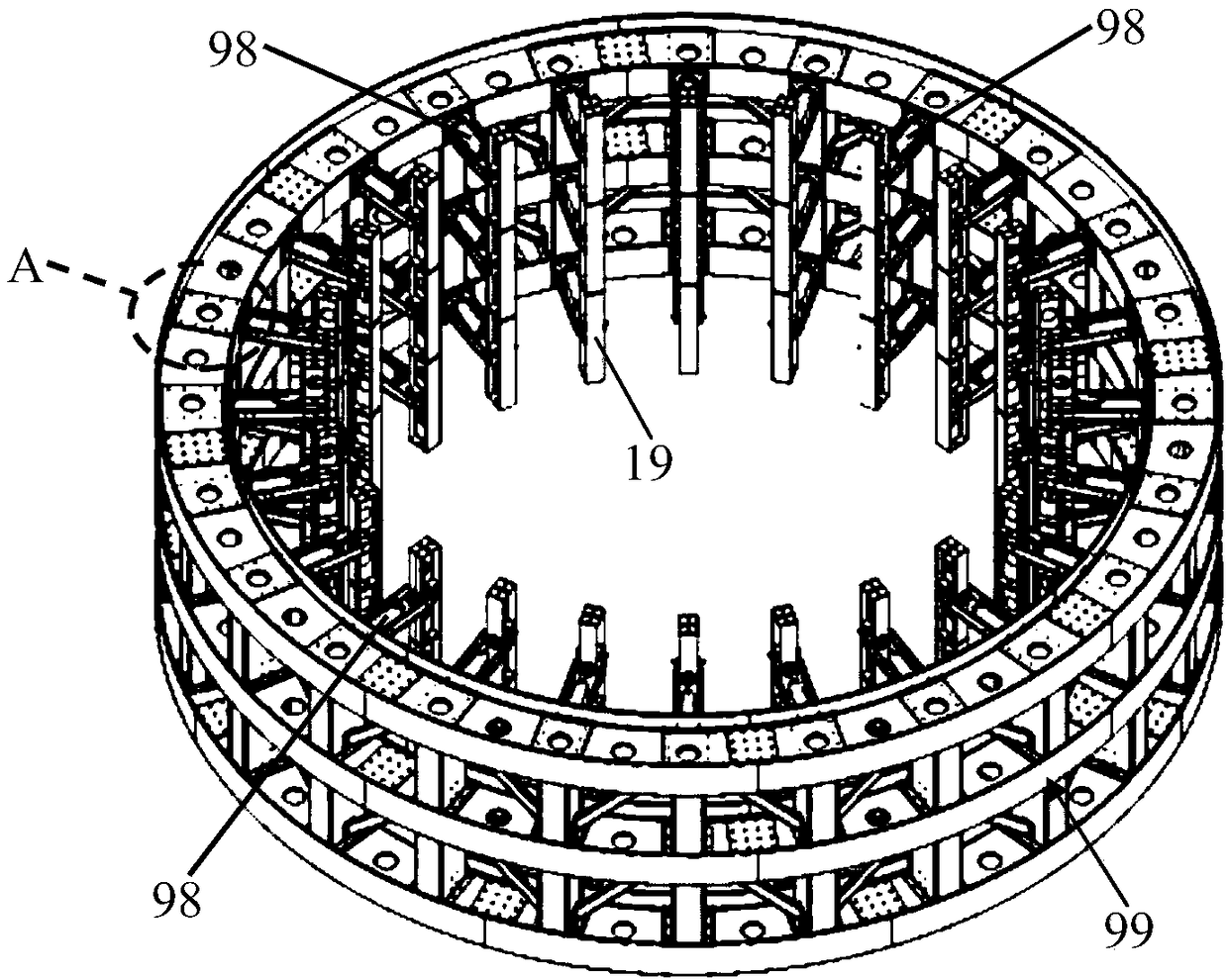

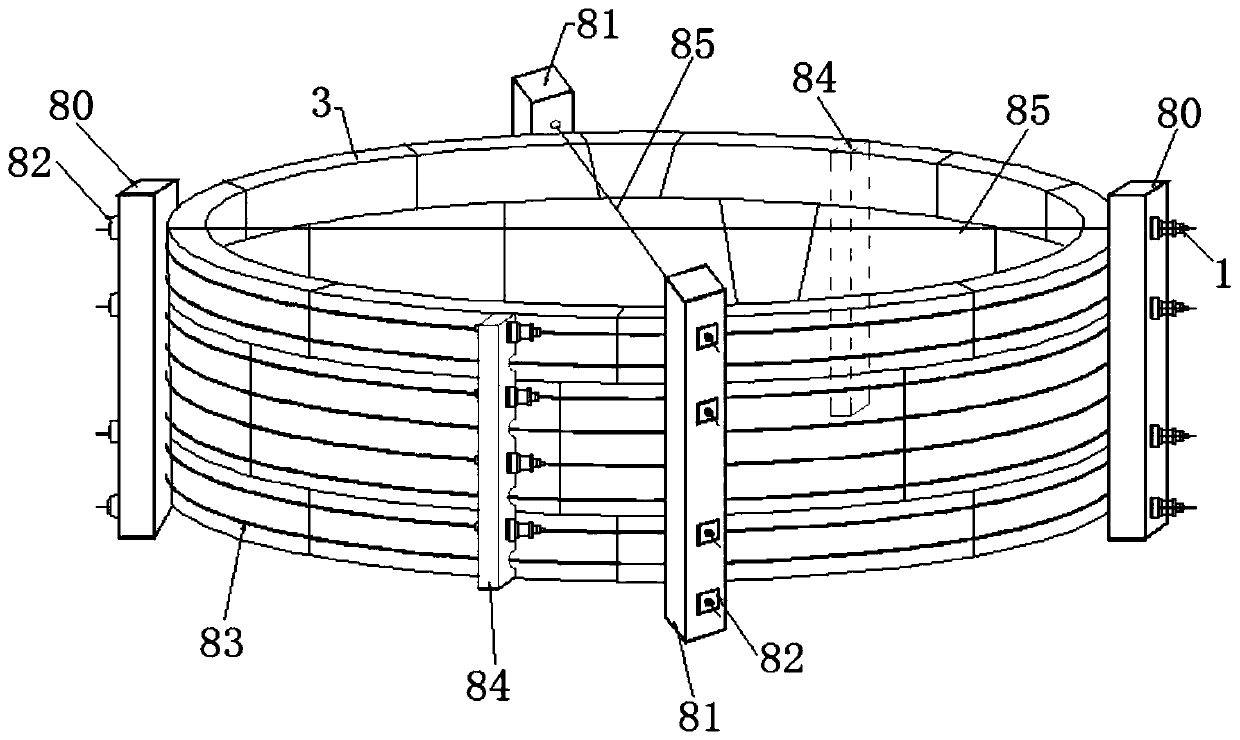

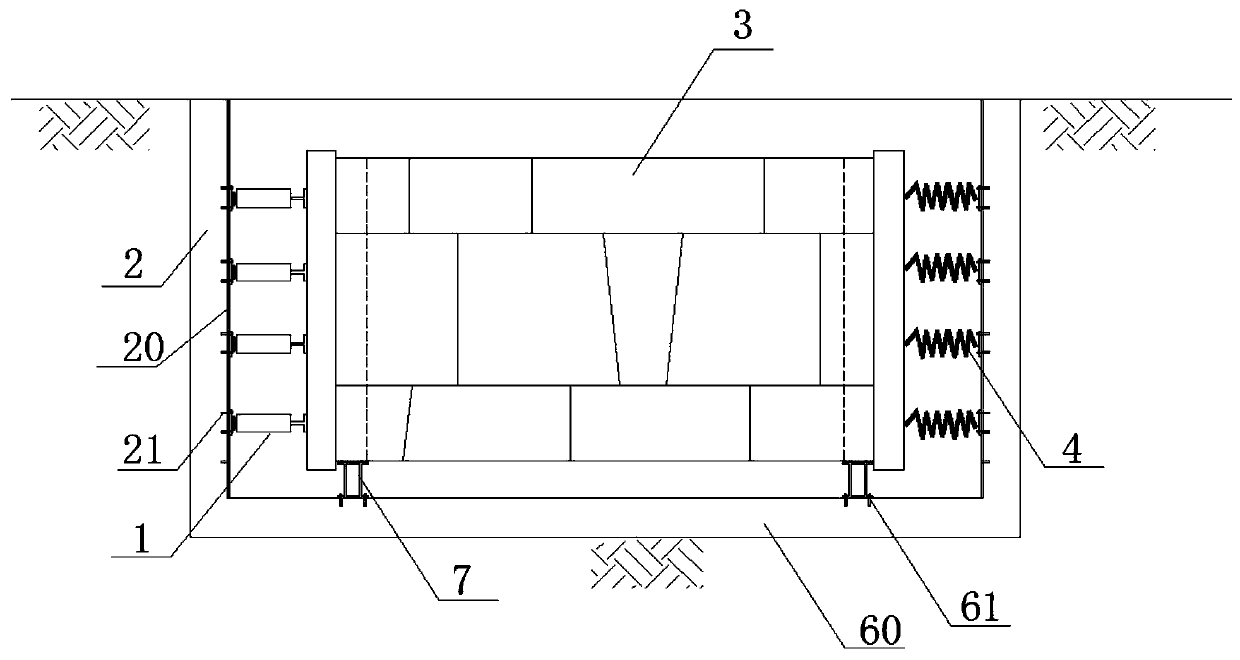

Loading device and method for shield tunnel lining ring full-scale test

PendingCN110618037ARealize the effect of asymmetric loadWide applicabilityMaterial strength using tensile/compressive forcesEngineeringShield tunnelling

The invention relates to the technical field of shield tunnels, and provides a loading device for shield tunnel lining ring full-scale test. The device comprises a jack for applying force, and furthercomprises a resistance spring and an annular reaction wall, wherein a test area for placing an annular test duct piece is arranged in the reaction wall, one end of the jack and one end of the resistance spring are both arranged on the reaction wall, and the other end of the jack and the other end of the resistance spring are both acted on the test duct piece. The invention further discloses a loading method for shield tunnel lining ring full-scale test. The continuous change among different working conditions can be realized by adjusting the jack pressure, the mechanical characteristics of the test duct piece in the whole loading process of a full-scale test can be simulated, the adjustment on different strata and different stress modes by the resistance spring can be realized, and the action of asymmetric load can be realized; and the loading device and method have wider applicability and accuracy.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Alloy vermicular graphite iron material

InactiveCN101818295AImprove thermal conductivityHeat cracking resistantCrack resistanceHeat conducting

The invention discloses an alloy vermicular graphite iron material, which is characterized by comprising the following components in percentage by weight: 3.1 to 3.6 percent of carbon, 2.1 to 2.85 percent of silicon, 0.91 to 1.25 percent of manganese, 1.05 to 1.45 percent of nickel, 0.10 to 0.25 percent of molybdenum, 0.10 to 0.20 percent of titanium, 0.01 to 0.04 percent of magnesium, less than 0.05 percent of phosphorus, less than 0.07 percent of sulfur and the balance of iron. The alloy vermicular graphite iron provided by the invention has excellent heat-conducting property as well as excellent comprehensive performance including heat crack resistance, wear resistance, corrosion resistance, low-temperature resistance, high strength and the like. 1:1 brake power bench full-scale tests show that the coefficient of the friction between a brake disc and a matched friction pair is stable and that the surface of the brake disc is free from hot marks, heat cracks and wear; and therefore, the material can ensure that the brake disc has a long service life. The material is suitable for manufacturing railway locomotive car brake discs.

Owner:EAST CHINA JIAOTONG UNIVERSITY

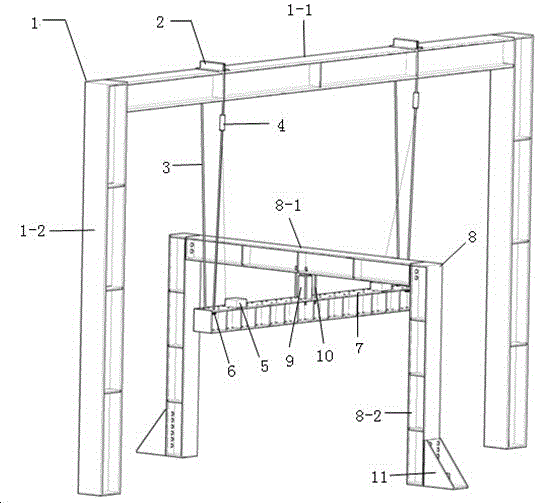

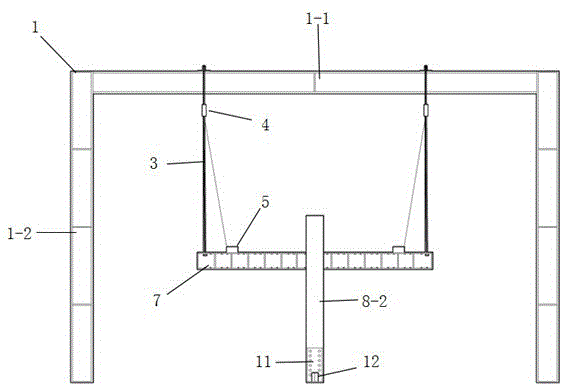

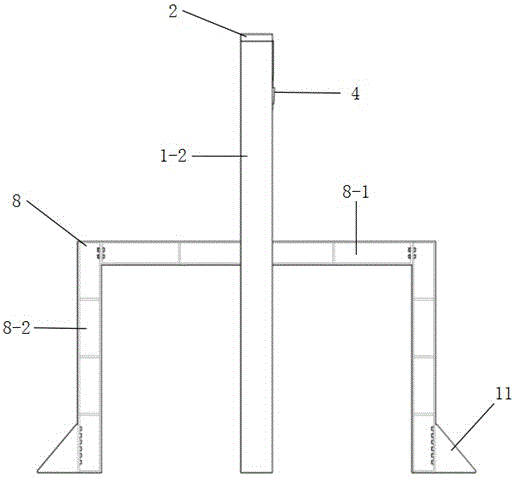

Self-balancing high heavy level load loading method and device

InactiveCN105043800AOvercome the defect that the load level is too smallSimple structureStructural/machines measurementEngineeringFull scale test

The invention provides a self-balancing high heavy level load loading method and device. The device comprises a carrying frame, a carrying frame beam and carrying frame columns. The carrying frame is composed of the parallel carrying frame beam and the horizontal carrying frame columns. Two limiting steel angles are arranged on the carrying frame beam. Each limiting steel angle is connected with a wire rope. A tension sensor is arranged on each wire rope. Each wire rope is connected with the end part of a power transmission distribution beam through a wire rope fixing device. Tension sensor display is arranged on the power transmission distribution beam. A jack and a reaction force pull rod are arranged on the power transmission distribution beam. A reaction force rack is arranged on the jack and the reaction force pull rod. The method and the device have the advantages that the structure is simple; a power transmission system is improved; through jack loading, the need of large tonnage loading is met in a full-scale test; the defect of small load rating in traditional suspension load is overcome; and the device has the advantages of easy installation, easy loading and secure and stable operation.

Owner:CHINA UNIV OF MINING & TECH

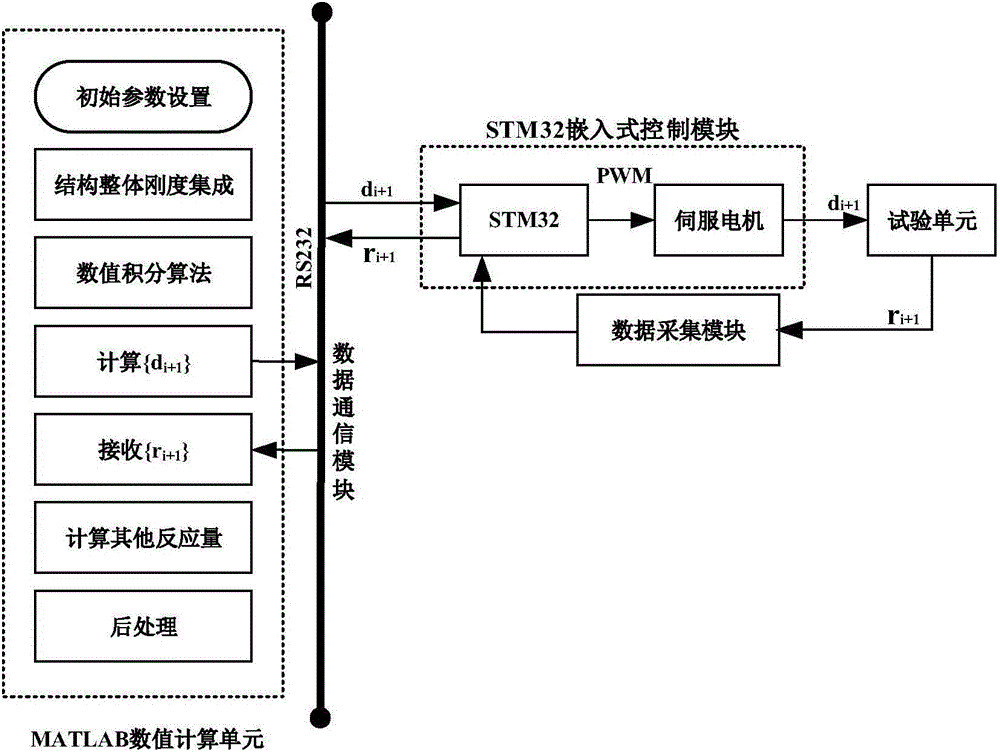

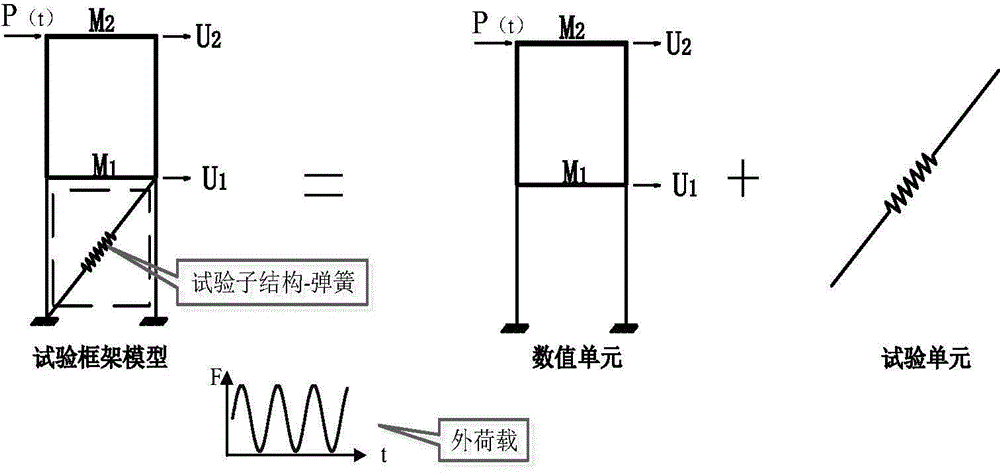

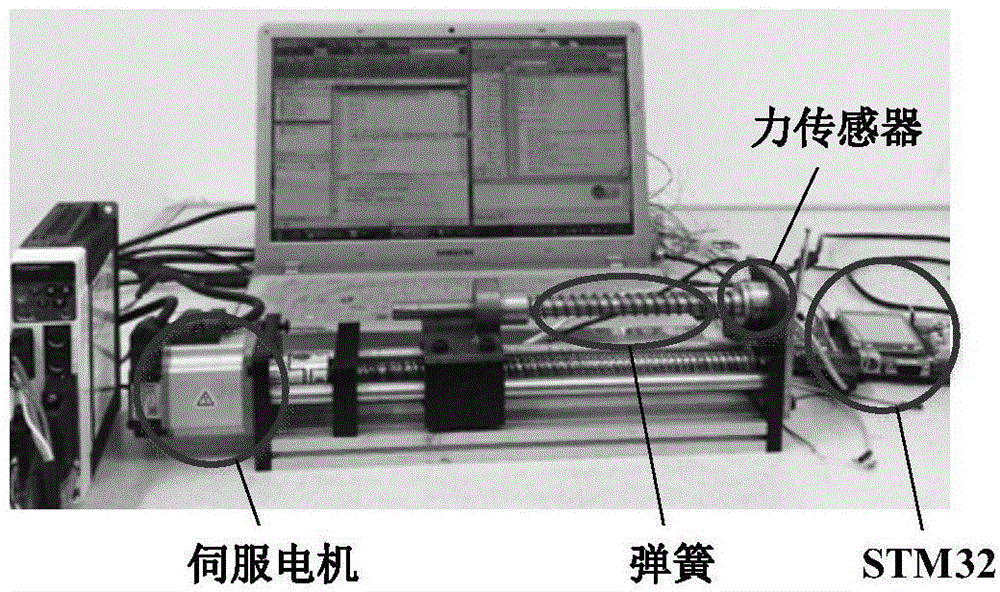

MATLAB-STM32 hybrid power test system and test method thereof

ActiveCN104807606ARich and flexible configurationReduce power consumptionVibration testingData acquisitionMATLAB

The invention discloses an MATLAB-STM32 hybrid power test system which comprises an MATLAB numerical calculation unit, a data communication module, an STM32 embedded control module, a data acquisition module and a test unit, wherein the STM32 embedded control module comprises an STM32 embedded controller and a servo motor. The invention further discloses a test method of the MATLAB-STM32 hybrid power test system. An MATLAB (matrix laboratory) is creatively combined with the STM32 embedded controller, and the advantages of rich and flexible configuration, low power consumption, easiness in control and high control precision of the STM32 embedded controller are taken. Real-time bidirectional communication between the MATLAB and the STM32 embedded controller is realized, a numerical simulation test of an engineering structure MATLAB numerical calculation unit and a real object test of a test unit are cooperatively performed, and the problems of singleness, high cost, too high hybrid power test system manufacturing cost and application field limitation of an electro-hydraulic servo actuator of a traditional hybrid test system are solved.

Owner:SOUTHEAST UNIV

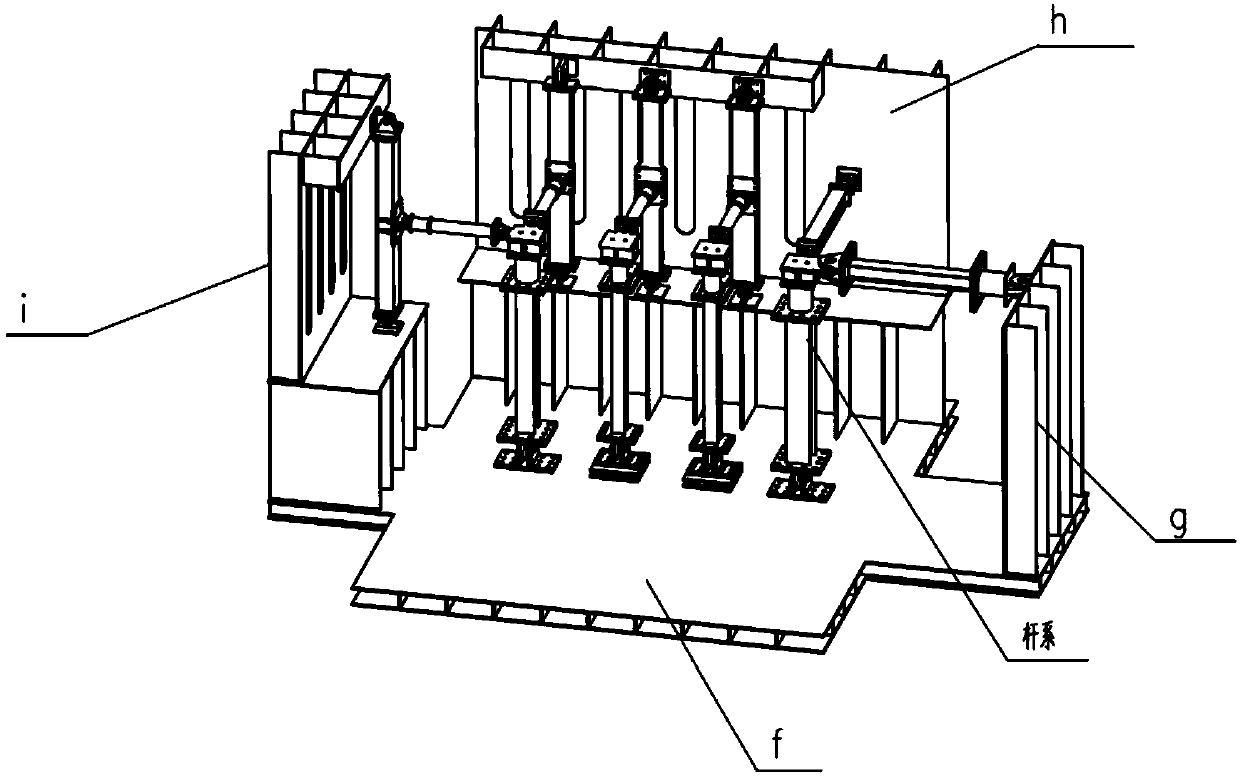

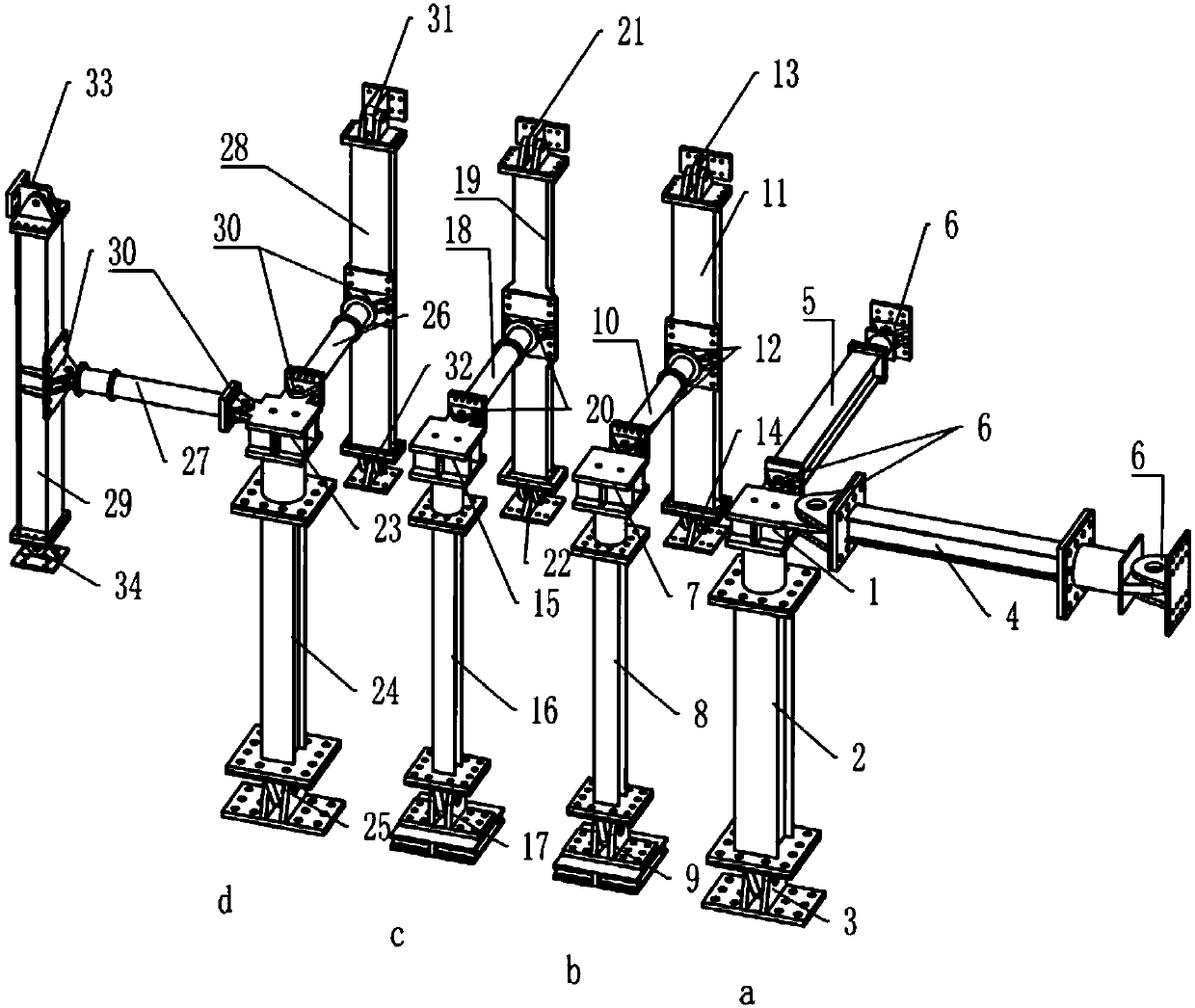

Aircraft vertical stabilizer and fuselage connection strength test support system

ActiveCN109094815AReduce risk of full-scale testingAircraft components testingSupporting systemVertical stability

A t support system for connecting a vertical stabilize surface to a fuselage of an aircraft is provided, includes two symmetrical sets of bar systems, each of said groups of bars comprises a front bars, middle-front bar system, middle and rear bar systems, the front bar system of the two sets of bar systems, middle-front bar system, The arrangement of the aft and middle members corresponds to thejoint of the vertical stabilizer of the aircraft, A link plate is arrange at that joint of each group of rods and the vertical stabilize surface of the aircraft, bolt holes for connecting with the joint of the vertical stabilizer surface of the aircraft are arrange on the connecting plate, and the front rods comprise a first joint, a first vertical rod, a first vertical fixed ear seat, a first lateral rod and a second lateral rod, wherein the front rods comprise a first joint, a first vertical rod, a first vertical fixed ear seat, and a second lateral rod. The invention simulates the connection constraint condition between the vertical stabilizer and the fuselage of the aircraft, tests the ultimate bearing capacity and the failure mode of the connection joint, and provides the test basis for the structural strength analysis and calculation, thereby reducing the risk of full-scale test.

Owner:HARBIN INST OF TECH

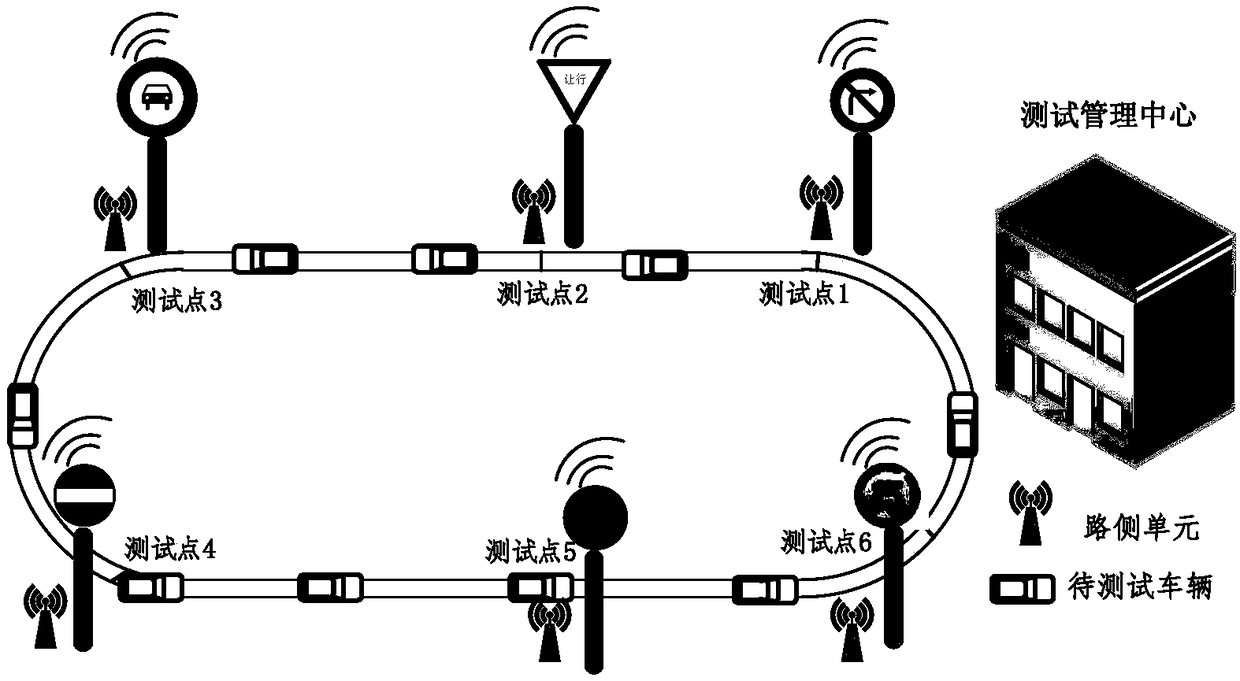

Autonomous sensing capability testing system and test method for ban traffic sign board of driverless car

The invention discloses an autonomous sensing capability testing system and test method for a ban traffic sign board of a driverless car. A tested vehicle, roadside units, a camera, a test managementcenter and ban traffic sign board test devices are arranged. The actual testing based on a testing field can test the actual autonomous sensing ban traffic sign board capability of a driverless car precisely, so that a phenomenon that driverless car break traffic regulations is avoided effectively. The ban traffic sign boards arranged at testing points can be replaced based on testing needs, so that the testing process is simplified substantially, the work efficiency is improved, and the manpower and material costs are saved; the autonomous sensing capability of the driverless car for the bantraffic sign board can be tested comprehensively; with testing of the autonomous sensing capability of the driverless car for the ban traffic sign board, a simple, effective, rapid, and accurate method is provided for the autonomous sensing performance valuation of the driverless car for the traffic sign board, so that a good platform is provided for evaluating the autonomous sensing capability ofthe driverless car for the traffic sign board effectively and simply.

Owner:CHANGAN UNIV

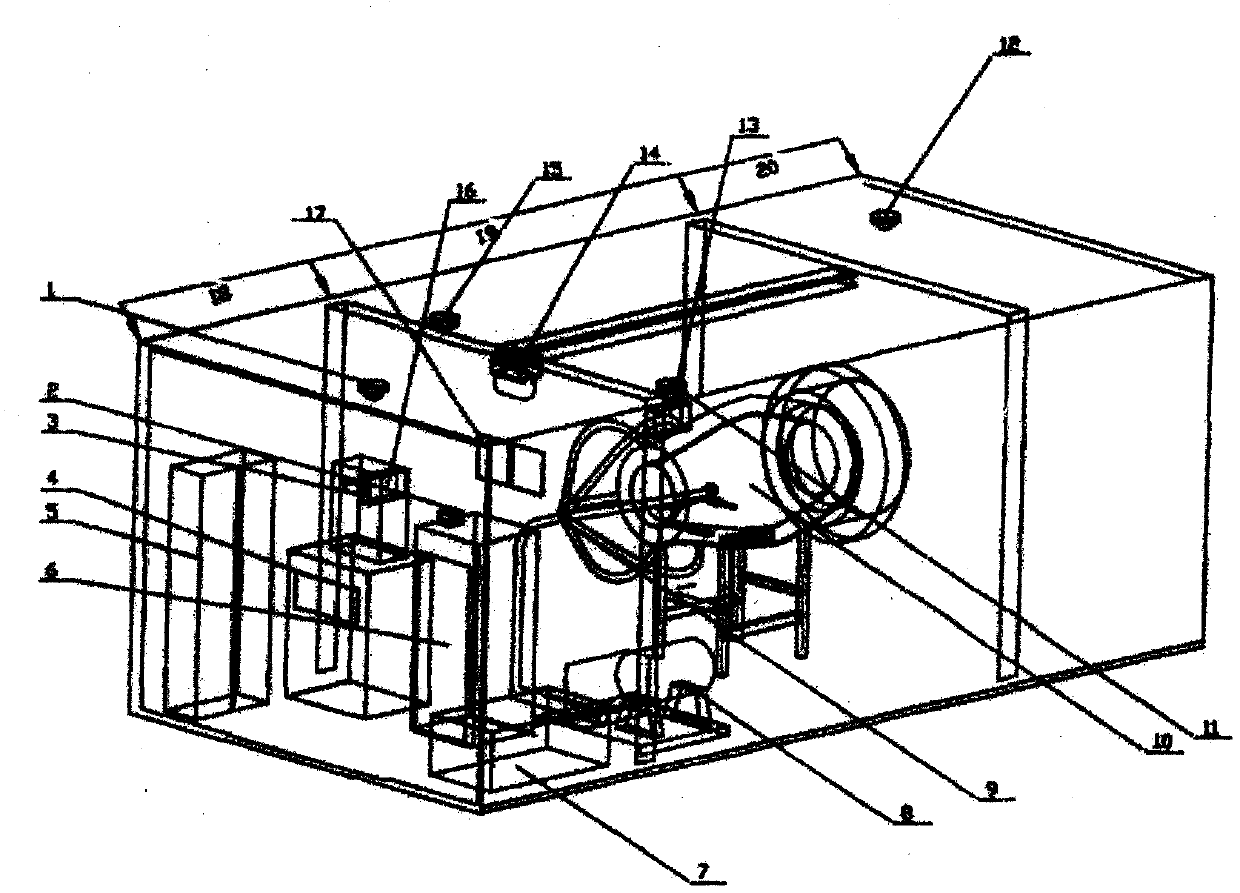

Aero-engine core engine room fire full-scale test device

The invention belongs to the field of aero-engine fireproof technologies and constructs an aero-engine core engine room fire full-scale test device. Through the device, typical working conditions of an actual engine room can be simulated, a fire and fire spreading in a core engine room can be truthfully reflected, and basic data can be provided for fireproof design and simulation of the core engine room of an aero-engine.

Owner:TONGJI UNIV +1

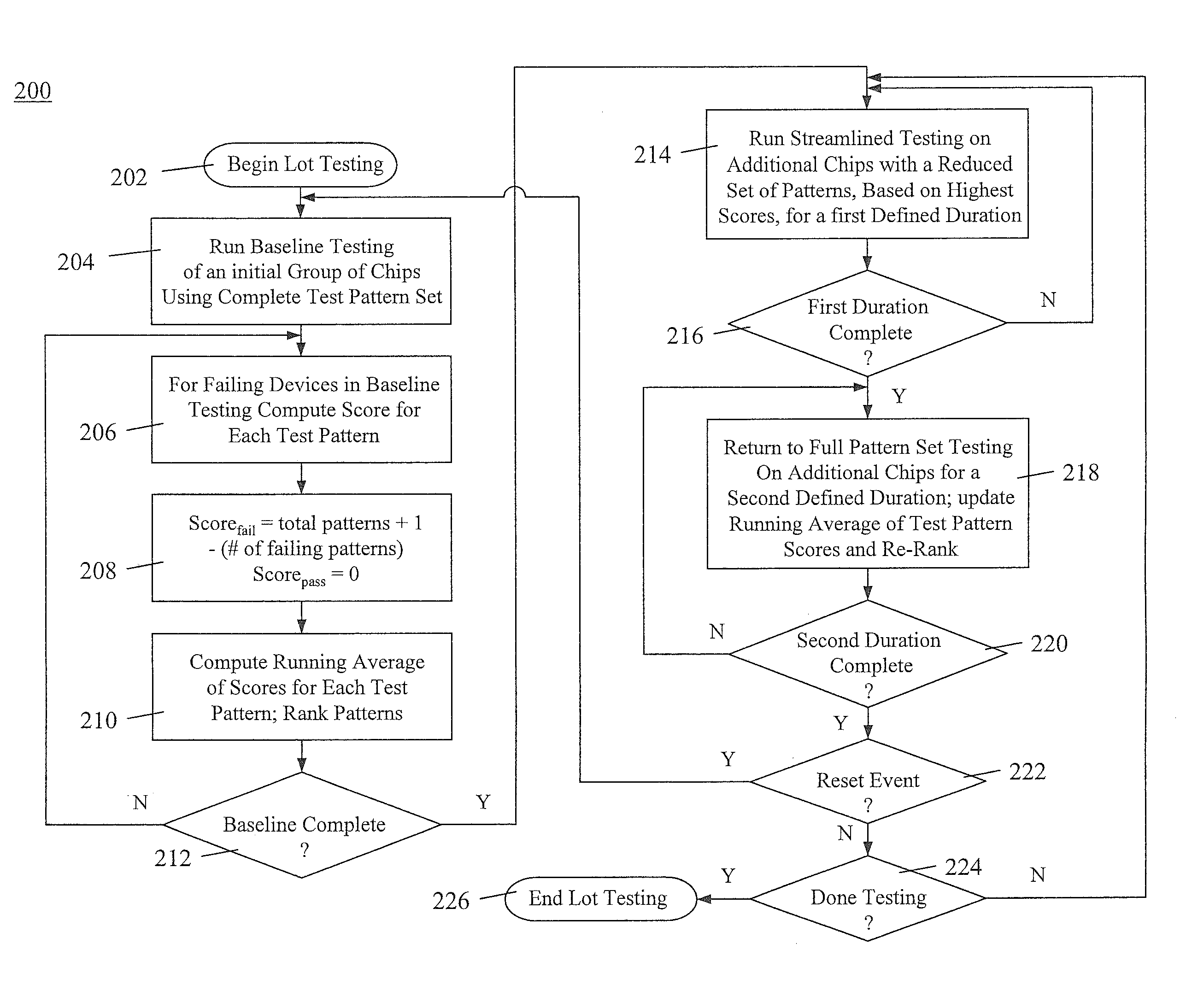

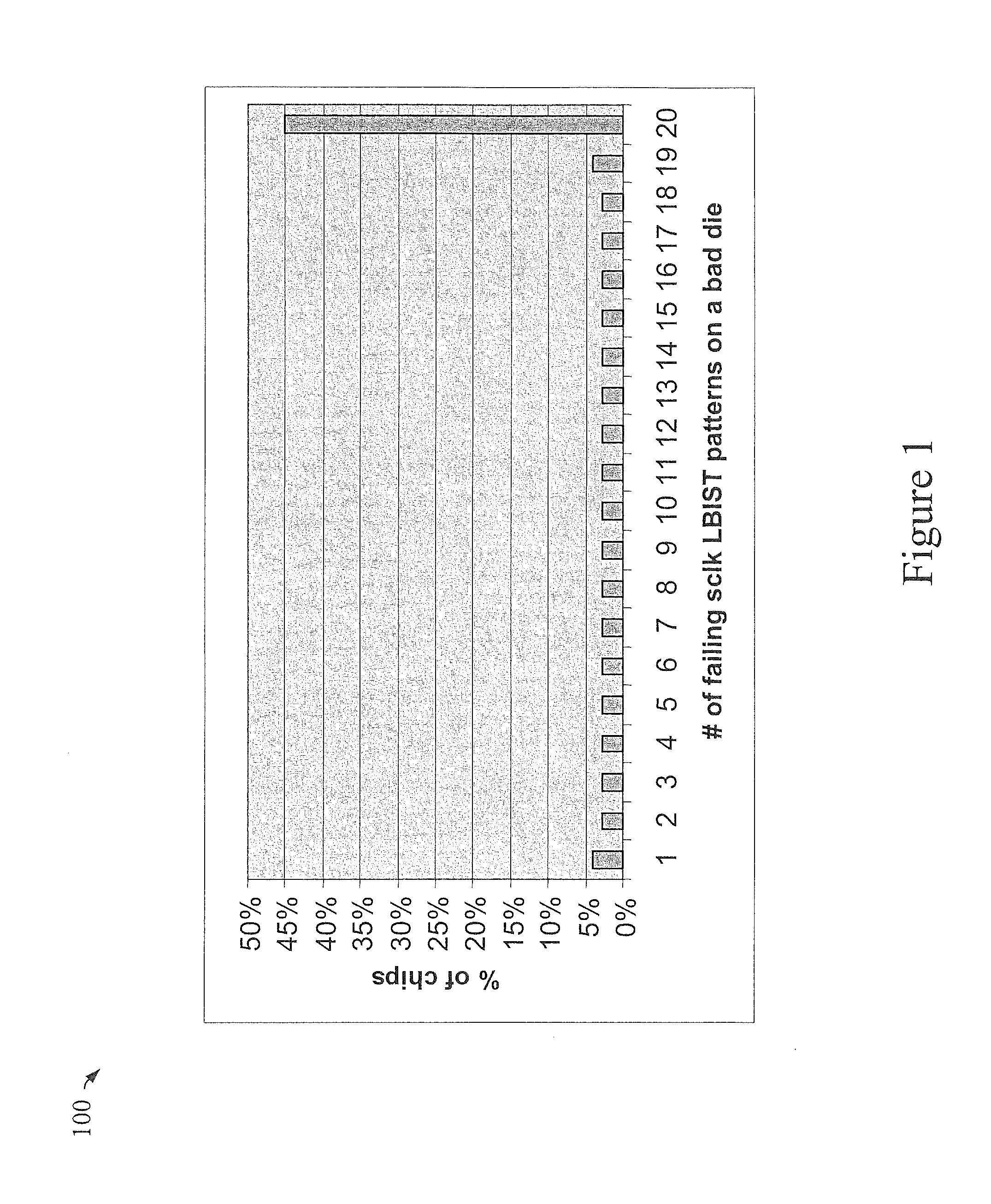

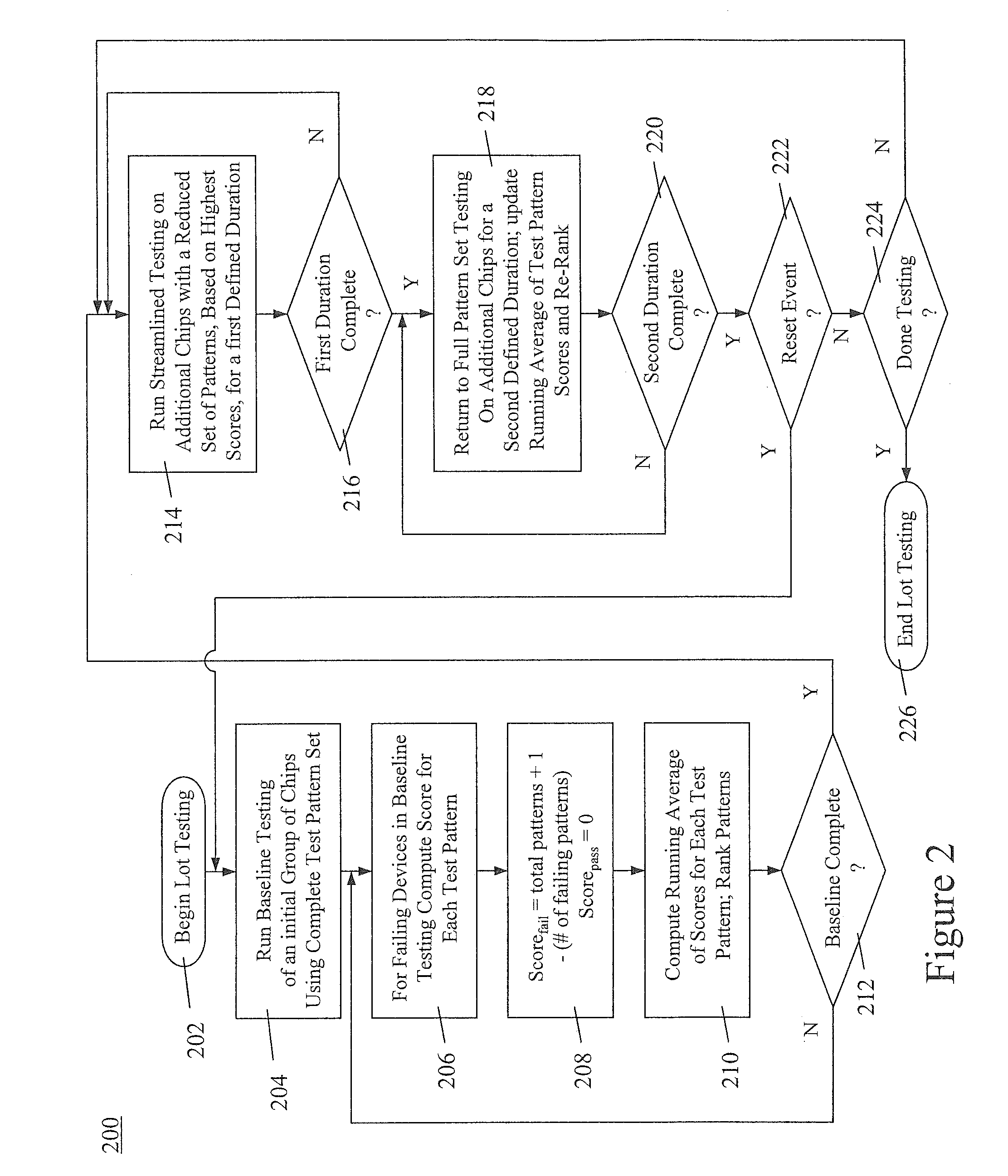

Integrated circuit test optimization using adaptive test pattern sampling algorithm

InactiveUS8689066B2Electronic circuit testingError detection/correctionBaseline testingTest optimization

A method of implementing integrated circuit device testing includes performing baseline testing of a first group of chips using a full set of test patterns, and for chip identified as failing, determining, a score for each test pattern in the full set. The score is indicative of an ability of the test pattern to uniquely identify a failing chip with respect to other test patterns. Following the baseline testing, streamlined testing on a second group of chips is performed, using a reduced set of the test patterns having highest average scores as determined by the baseline testing. Following the streamlined testing, full testing on a third group of chips is performed using the full set of test patterns, and updating the average score for each pattern. Further testing alternates between the streamlined testing and the full testing for additional groups of chips.

Owner:IBM CORP

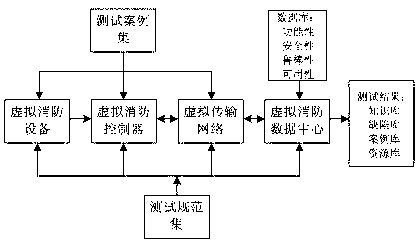

Fire protection Internet-of-things system testing method

InactiveCN103281221AImplement testMeets requirementsData switching networksSoftware simulation/interpretation/emulationFire protectionData center

The invention discloses a fire protection Internet-of-things system testing method. The problems that in the prior art, a fire protection Internet-of-things system testing method is not complete in function, comprehensive testing cannot be carried out on a fire protection Internet-of-things system, and requirements of a user can not be met are solved. The fire protection Internet-of-things system testing method comprises the steps that virtual fire protection equipment, a virtual fire protection controller, a virtual transmission network and a virtual fire protection data center corresponding to real equipment are established; the specific working conditions of the virtual fire protection equipment, the virtual fire protection controller and the virtual transmission network are simulated according to a testing case set, the fire protection Internet-of-things system is tested according to the index requirements in the data base; test results are output according to the index requirements in the data base and the test data of the testing case set. According to the scheme, the purpose that the fire protection Internet-of-things system is comprehensively tested and evaluated, so that normal stable operation of the system is guaranteed is achieved, and high practical value and high popularization value are achieved.

Owner:CHENGDU UNIV OF INFORMATION TECH

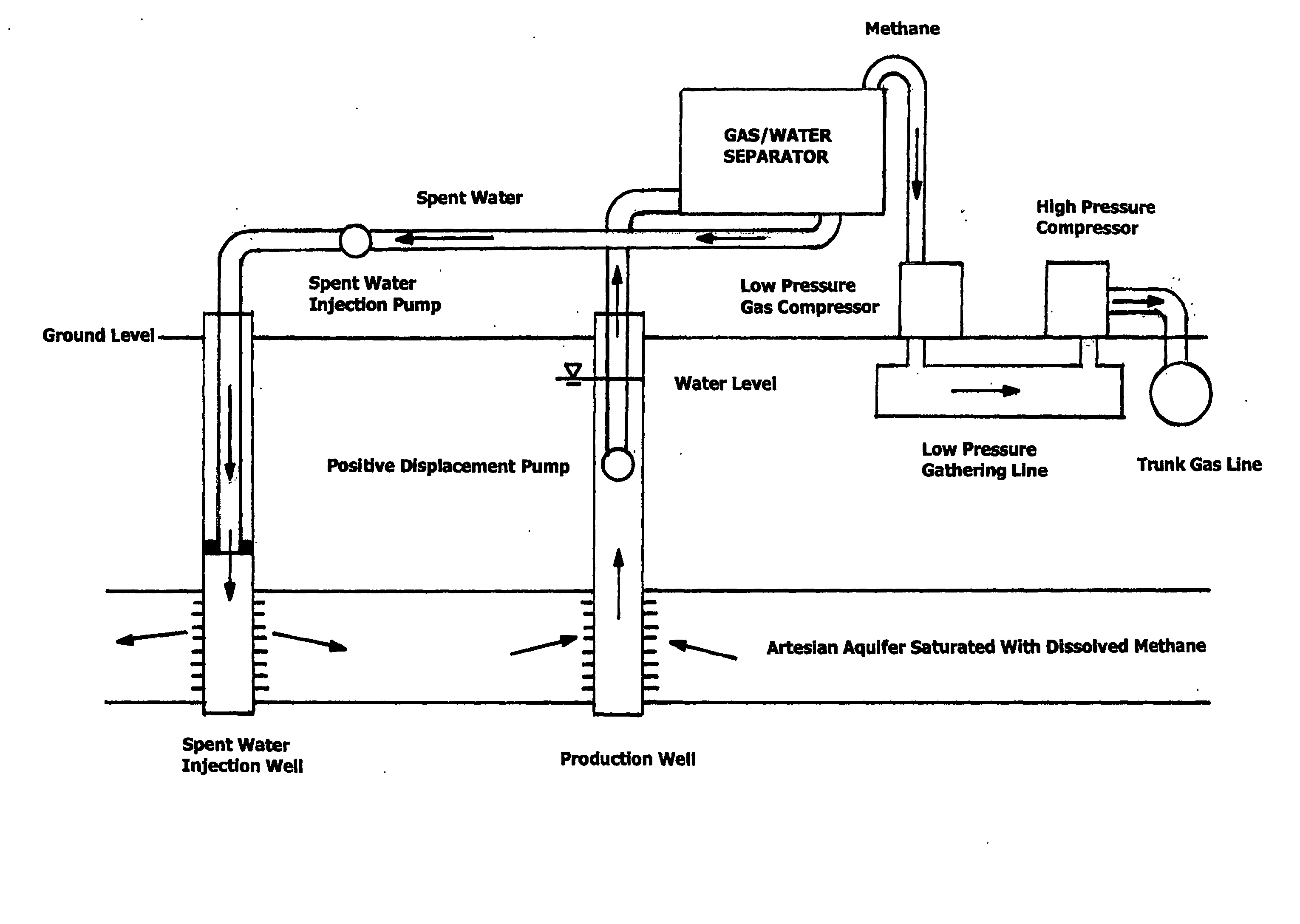

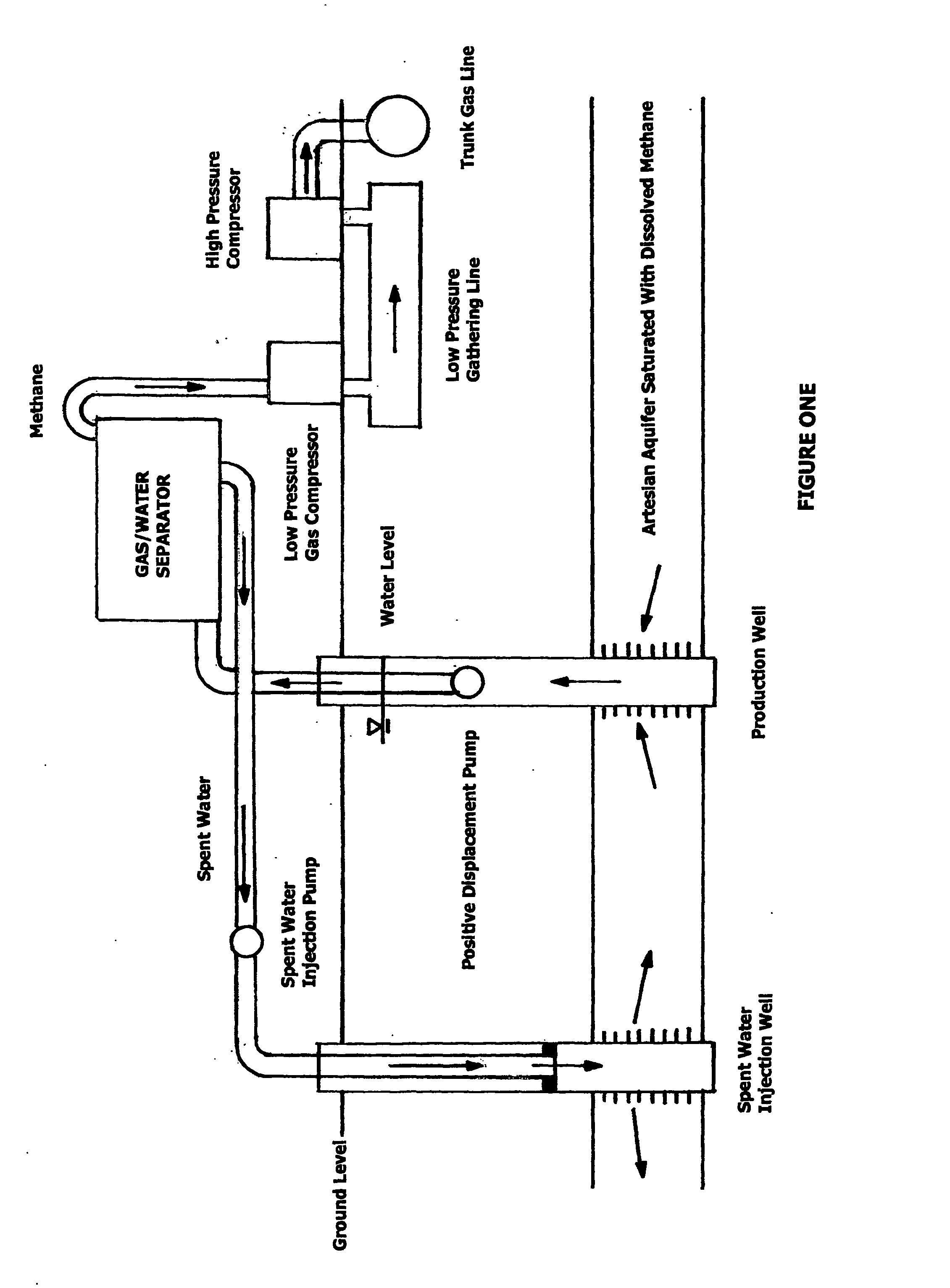

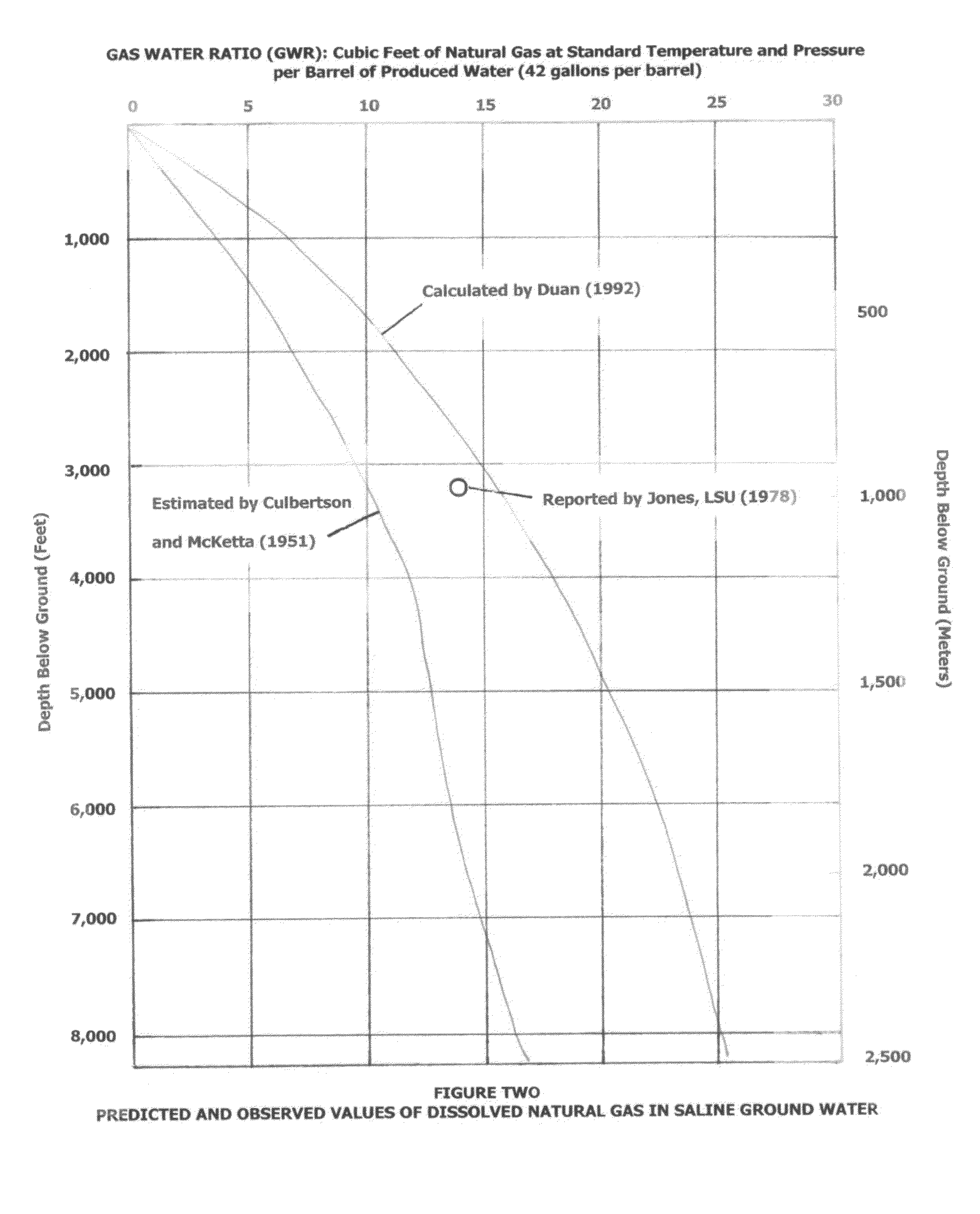

Process for extracting dissolved methane from hydropressured aquifers

One undeveloped alternative fuel is methane dissolved in ground water. Equipment for extracting methane from ground water is readily available. This Application presents a process to produce and use dissolved natural gas in the United States. The process includes the use of production wells, pumps, gas / water separators, compressors, low pressure gathering lines, and water disposal wells. Dissolved methane is present in virtually every basin now known to produce oil and dry gas. The Great Valley of California alone contains undeveloped dissolved methane resources of about 1,200 trillion cubic feet (TCF). Dry gas production in 150 years was about 10 TCF. The first full scale test of the extraction process was completed on Jul. 7-8, 2010 in California. Laboratory analyses of the gas produced showed that it was equal in heat value (about 940 to 975 BTU per cubic foot) to dry gas produced from the same field.

Owner:PLAYER GARY FARNSWORTH

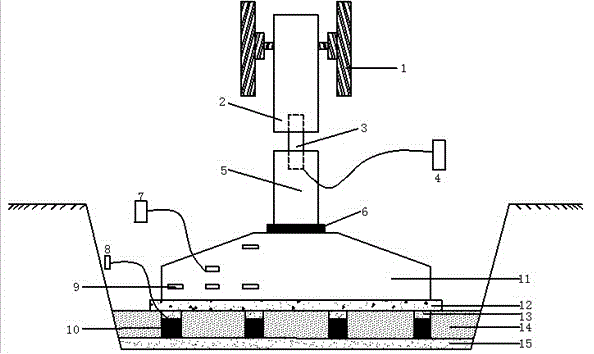

Full-scale testing apparatus for spread foundations

ActiveCN105862944AImprove experimental efficiencyLow costFoundation testingMeasurement deviceEngineering

The invention discloses a full-scale testing apparatus for spread foundations. The full-scale testing apparatus comprises a foundation pit and a hydraulic static pile press. Base reaction measuring devices which are buried in a backfilled soil layer are arranged at the bottom of the foundation pit, a spread foundation test piece is arranged above the base reaction measuring devices, a force transfer short column is mounted on the top of the spread foundation test piece, a strain measuring device is arranged on the spread foundation test piece, and a force transfer plain concrete pile which is positioned above the force transfer short column is clamped at a jaw of the hydraulic static pile press. The full-scale testing apparatus has the advantages that reaction frame jack systems are replaced by the hydraulic static pile press, accordingly, the experimental efficiency of full-scale tests for concrete spread foundations with large width-height ratios can be effectively improved, the cost can be saved, and the time can be shortened; fine sand with the thickness ranging from 4 centimeters to 10 centimeters needs to be arranged on steel-wire soil pressure cells, so that stress can be effectively distributed, and the test precision can be improved; a rigid pressure plate is welded on the top of the spread foundation test piece, accordingly, sections of pillars can be simulated, and load applied by the force transfer short column can be uniformly transmitted to the spread foundation test piece.

Owner:STATE GRID CORP OF CHINA +4

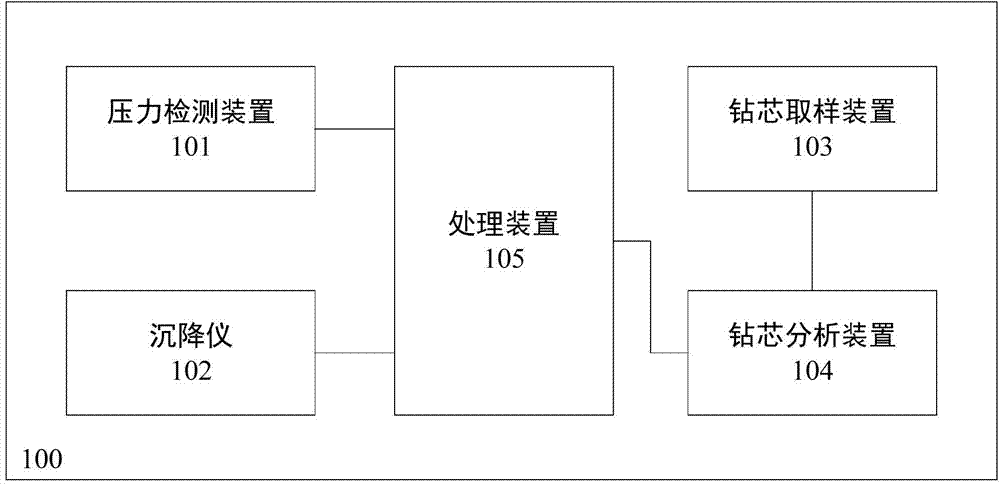

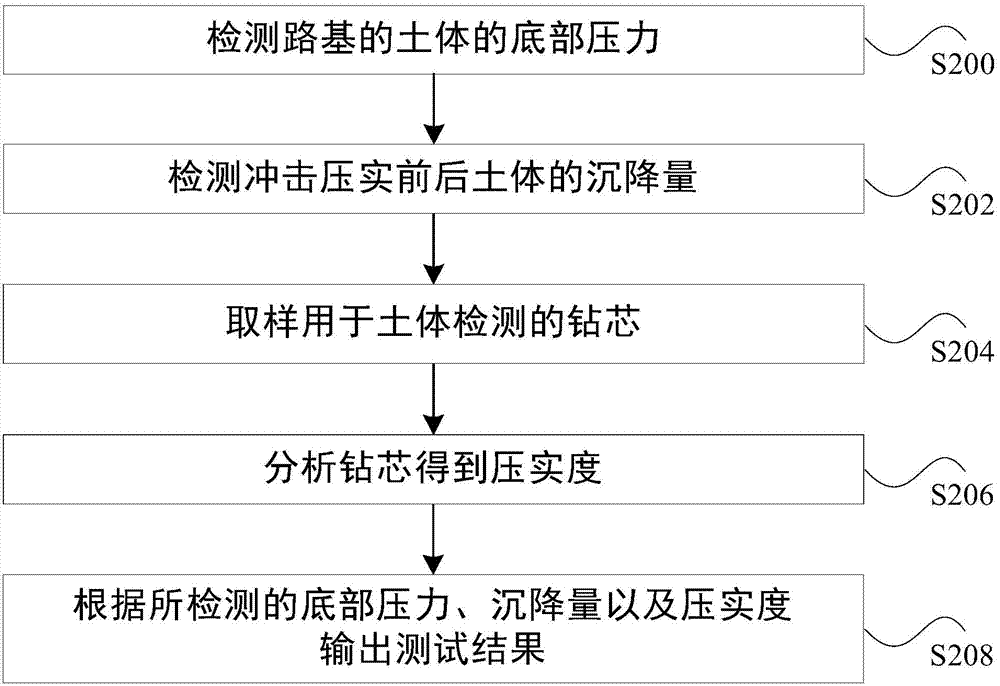

System and method for testing impact compacted roadbed

InactiveCN103669318AComprehensive evaluation of impact compaction effectBest impact compaction methodIn situ soil foundationSoil scienceBottom pressure

The invention discloses a system and method for testing an impact compacted roadbed. The system comprises a pressure detection device, a settlement gauge, a drilled core sampling device, a drilled core analyzing device and a treatment device, wherein the pressure detection device is arranged to detect the bottom pressure of soil mass of the roadbed, the settlement gauge is arranged to detect the settlement amount of the soil mass before impact compacting and after impact compacting, the drilled core sampling device is arranged to sample a drilled core used for soil mass detection, the drilled core analyzing device is arranged to analyze the drilled core sampled by the drilled core sampling device so that the degree of compaction can be achieved, and the treatment device is arranged to output a testing result according to the detected bottom pressure, the settlement amount and the degree of compaction. According to the technical scheme, parameters of the bottom pressure, the settlement amount and the degree of compaction of the soil mass of the roadbed, which can reflect the impact compacting effect of the soil mass, can be tested comprehensively, so that the impact compacting effect is evaluated comprehensively; an optimal impact compacting mode can be found by technicians by using the output testing result in an assisting manner.

Owner:CHINA SHENHUA ENERGY CO LTD +2

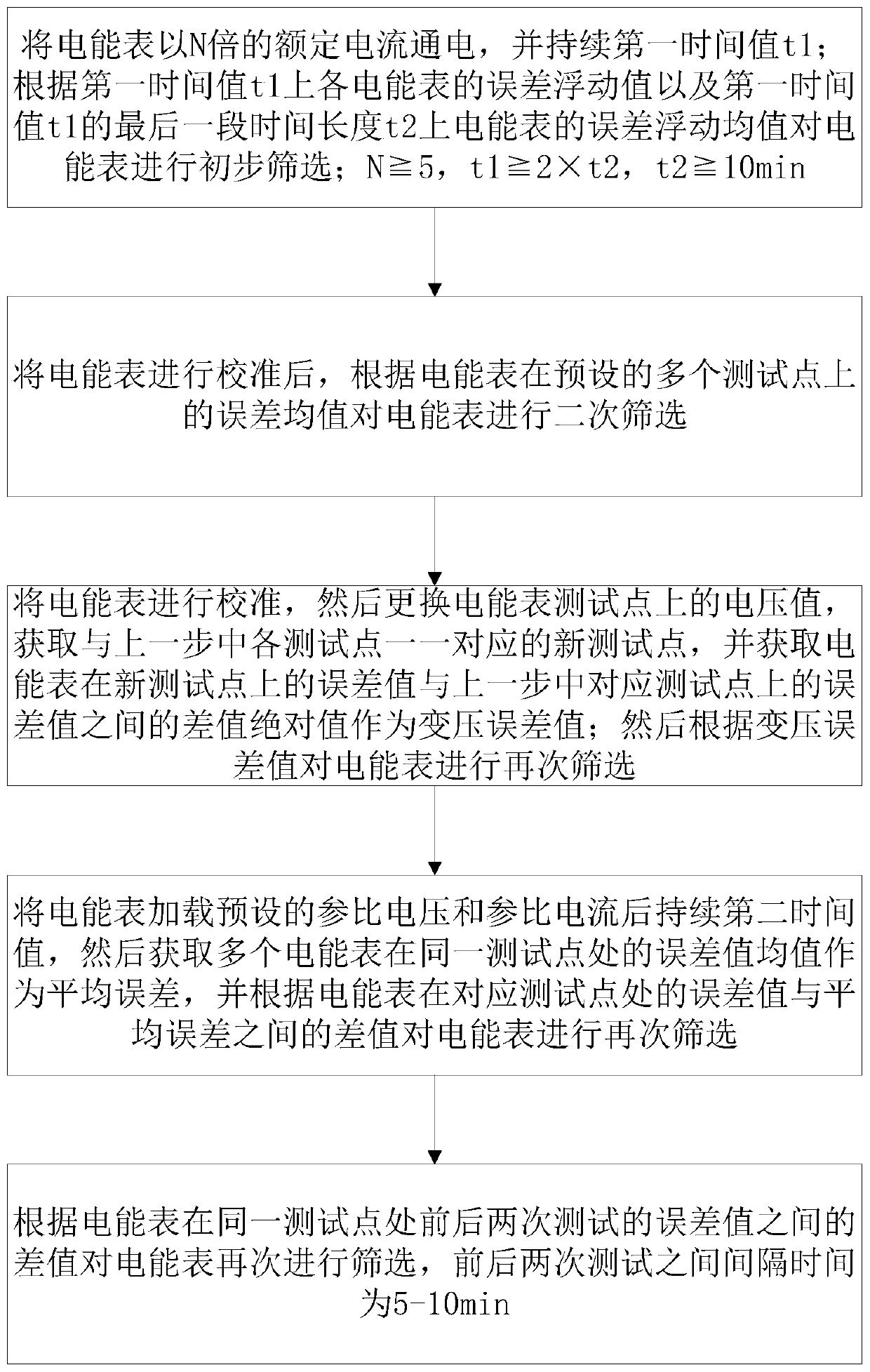

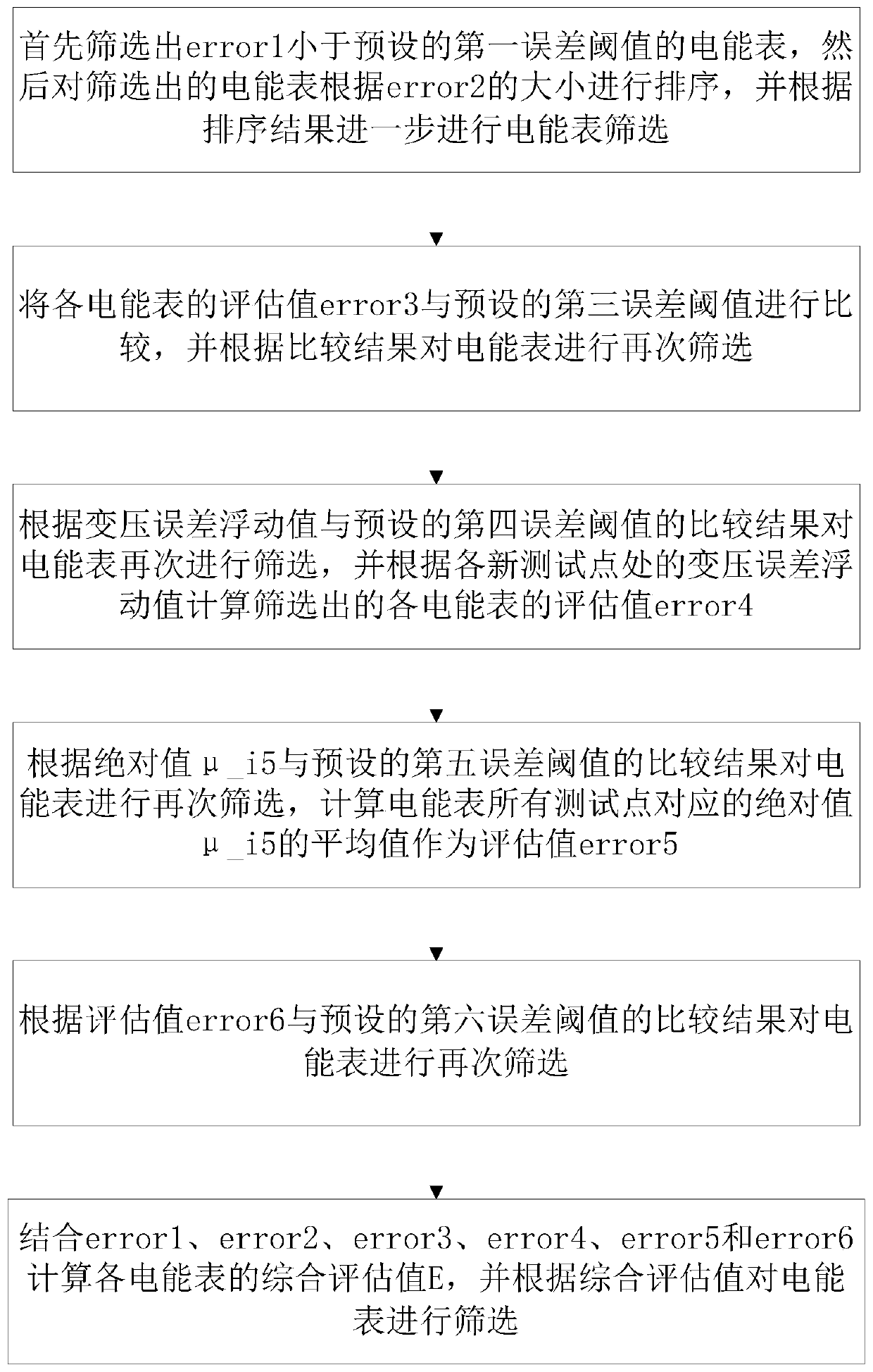

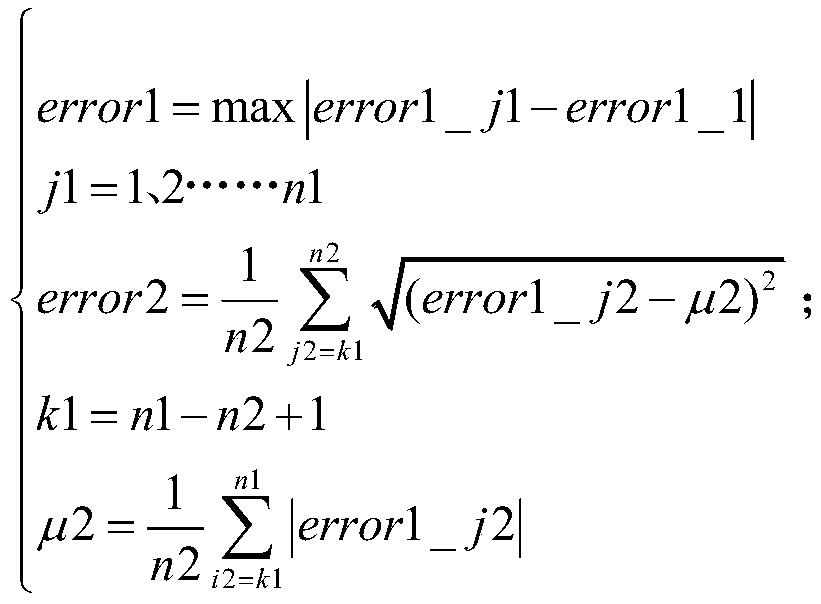

Automatic screening method based on error testing for electric energy meter

InactiveCN110426669AFlexible settingsComprehensive and accurate testingElectrical measurementsScreening methodElectrical current

The invention provides an automatic screening method based on error testing for an electric energy meter. The method comprises the steps that the electric energy meter is energized with N times of rated current, and error testing in a self-heating state is achieved; secondary screening is conducted on the electric energy meter according to the error mean value of the electric energy meter at multiple preset test points; an absolute value of the difference between an error value of the electric energy meter at the new test point and the error value at the corresponding test point in the previous step serves as a voltage transformation error value, and then the electric energy meter is re-screened according to the voltage transformation error values; comprehensive testing of the individual performance of the electric energy meter is achieved; the error mean value of multiple electric energy meters at the same test point is obtained and serves as an average error, and the electric energymeter is re-screened according to the difference value between the error value of the electric energy meter at the corresponding test point and the average error; balance testing on the overall quality of multiple energy meters is achieved.

Owner:ANHUI ZENITH ELECTRICITY & ELECTRONICS

Support device for aircraft tail and fuselage connection strength test

ActiveCN109110153AReduce risk of full-scale testingAxial forces can be measured and monitoredAircraft components testingVertical barEngineering

The invention provides a support device for aircraft tail and fuselage connection strength test, and the support device includes two symmetrical sets of bar systems, each of said groups of bars comprises a front bar, a middle-front bar system, a middle-rear bar system, and a rear bar system, the arrangement of the front bar system, the middle-front bar system, the middle-rear bar system, and the rear bar system of the two sets of bar systems correspond to the position of the joint of the aircraft's vertical tail and is set vertically. The front bar system comprises a joint fixedly, a front barvertical bar and a front bar connecting seat that are fixedly connected from the top to the bottom; the middle-front bar system and the middle-rear bar system have the same structure, each comprisinga joint fixedly connected from the top to the bottom, a vertical bar and a connecting seat; and the rear bar system comprises a joint fixedly connected from the top to the bottom, a rear bar verticalbar and a rear bar connecting seat. The invention simulates the connection constraint condition of the aircraft vertical tail and the fuselage, tests the ultimate bearing capacity and the failure mode of the connection joint, verifies whether the connection form design of the vertical tail and the fuselage is reasonable, provides the test basis for the structural strength analysis and calculation, thereby reducing the risk of the full-scale test.

Owner:HARBIN INST OF TECH

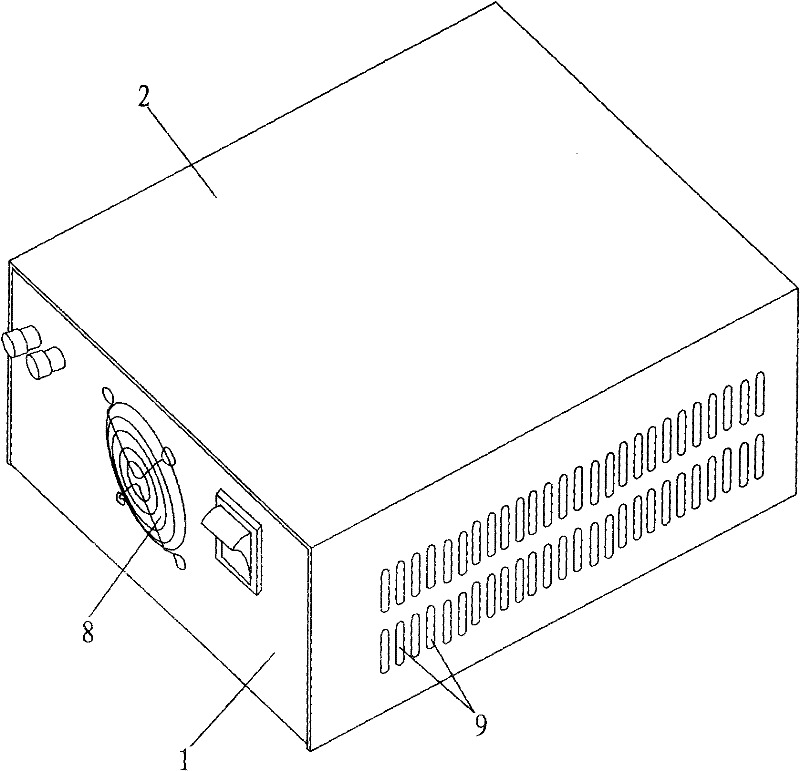

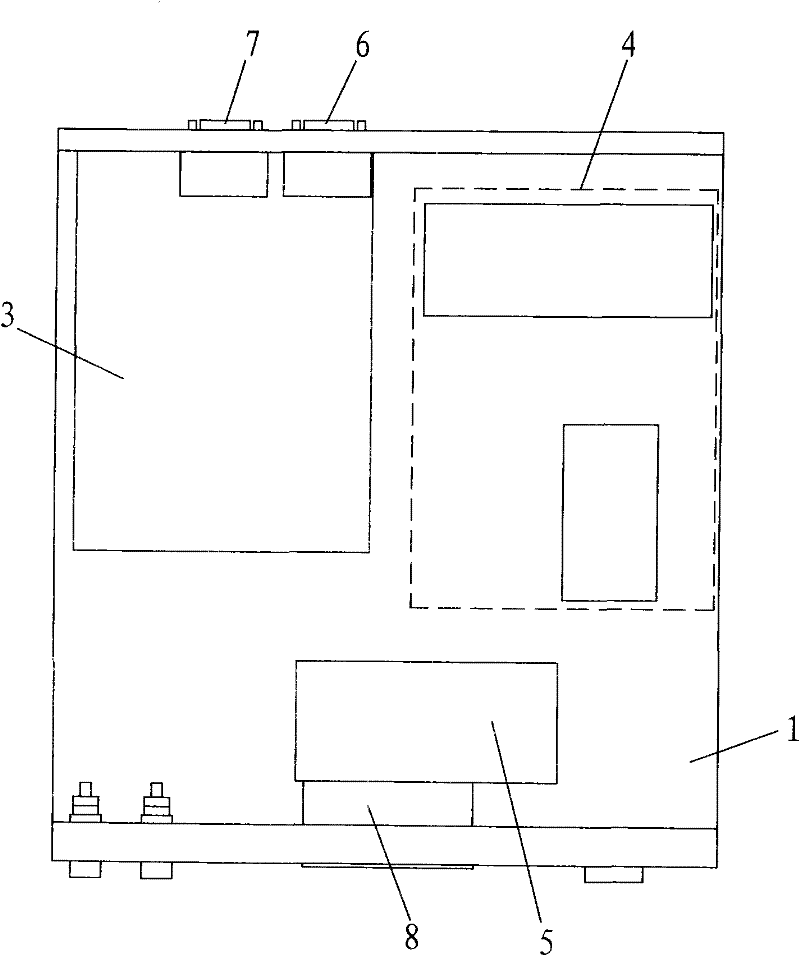

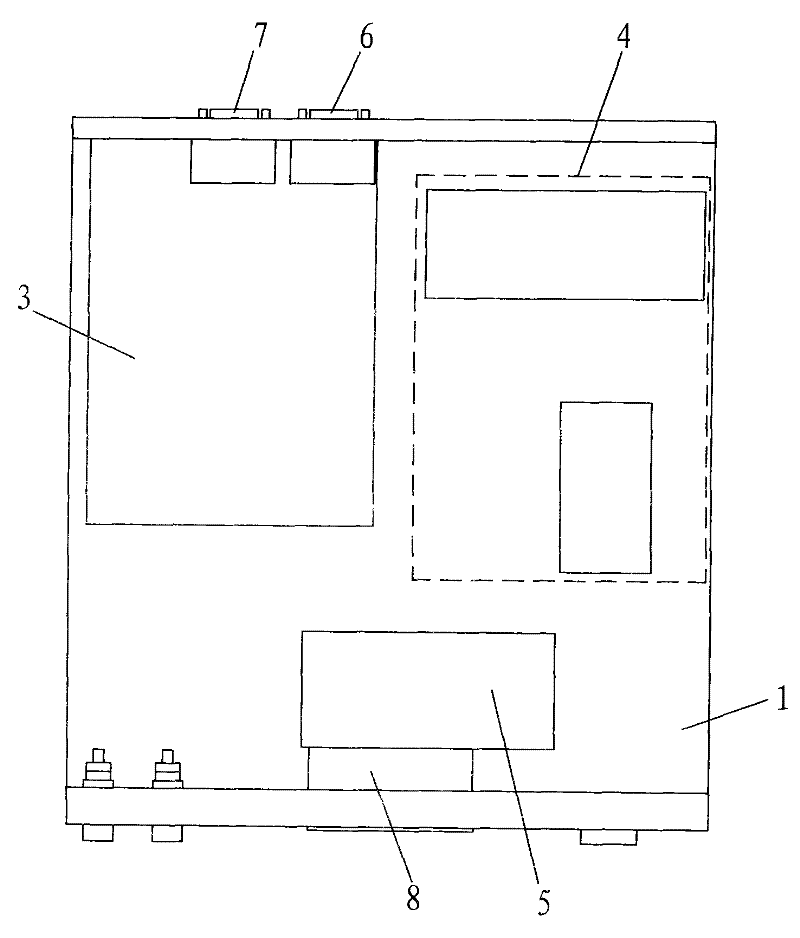

Battery protection testing instrument

The invention relates to the technical field of battery testing equipment, and in particular relates to a battery protection testing instrument. The battery protection testing instrument comprises a main casing and a casing cover on the main casing, wherein a battery testing equipment main board, a power supply module and a large-power switch tube electrically connected with one another are arranged in the main casing; the battery testing equipment main board is electrically connected with an analog interface, and a serial interface for communicating with PCM (pulse code modulation); and the analog interface and the serial interface protrude out of the main casing. By using the analog interface and the serial interface to connect a computer and the PCM, the battery protection testing instrument can automatically collect the parameters of a protection plate by use of testing software after the testing is completed, and can summarize the collected parameters to comprehensively test the battery protection plate conveniently. The battery protection testing instrument can be used for testing laptop batteries, semi-products and final products, with the advantages of diverse testing functions and flexibility in adjustment of testing parameters, thereby effectively ensuring the improvement on the production capacity and the product performance.

Owner:东莞市海拓伟电子科技有限公司

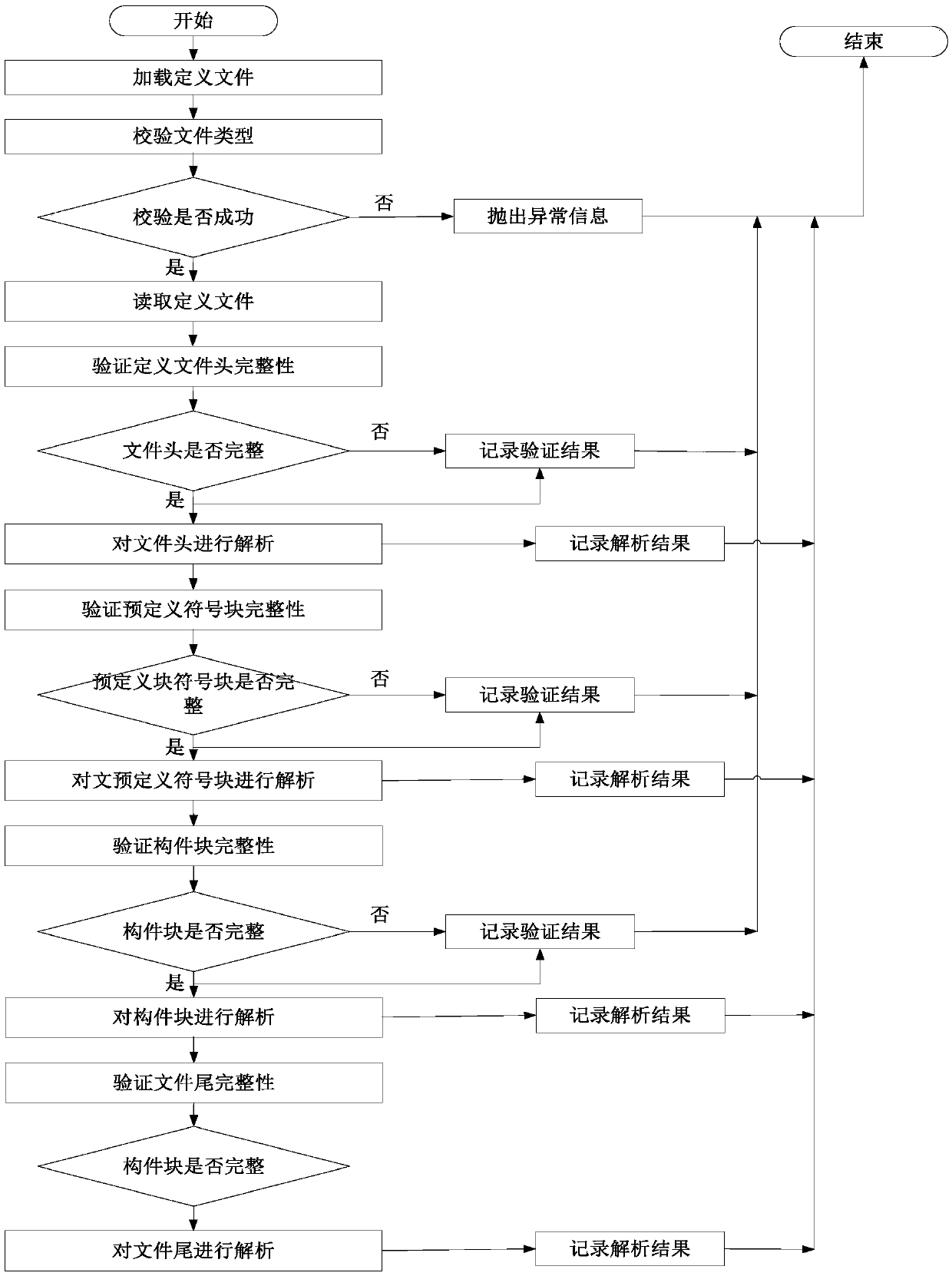

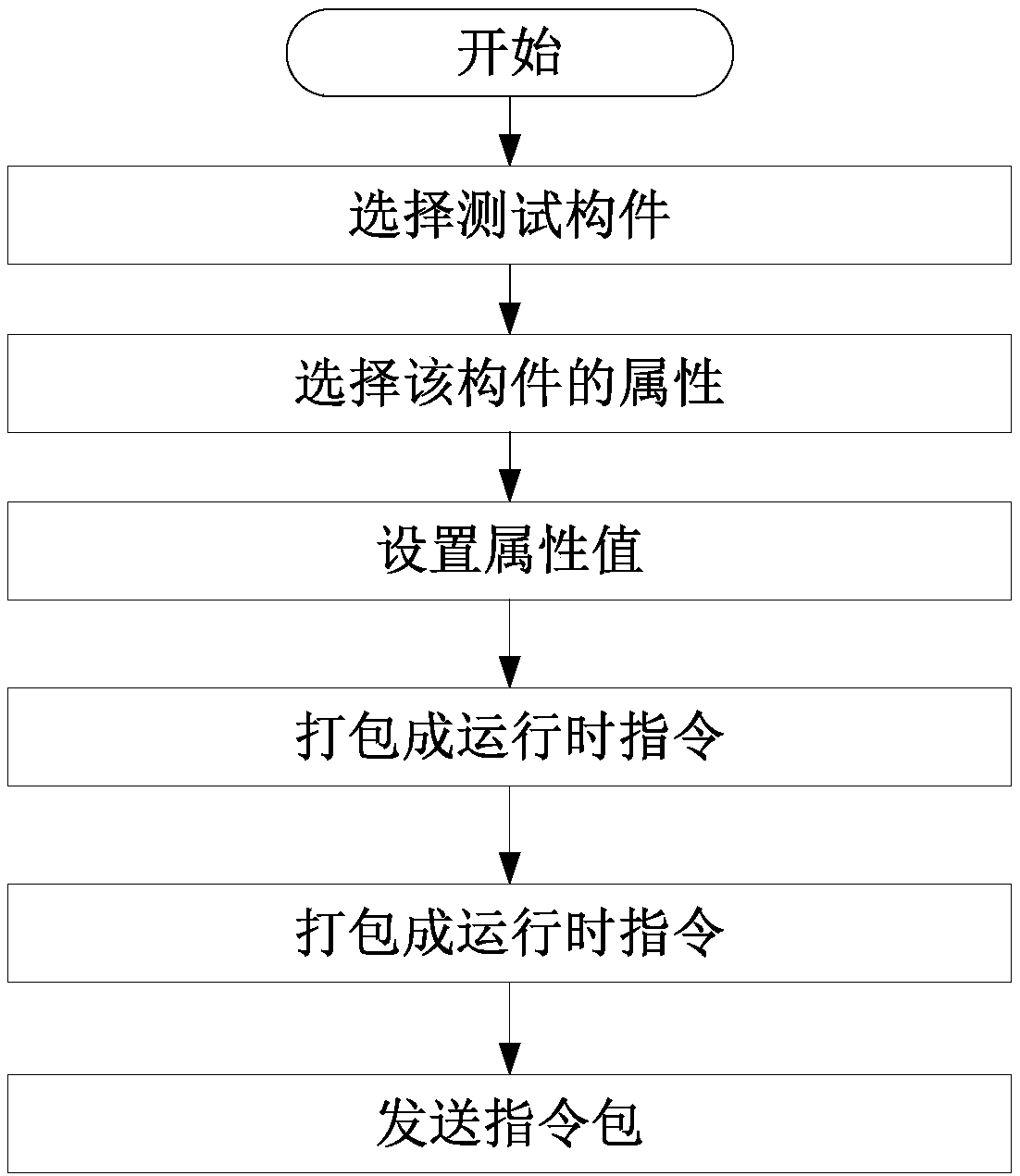

Cabin display system testing method based on ARIINC 661 standard

InactiveCN107719698AImplement testQuality improvementAircraft components testingSupporting systemSystem integration

The invention provides a cabin display system testing method based on the ARIINC 661 standard. A define file (DF file) based on the ARIINC 661 standard is analyzed at the file structure level and instruction level, the analysis result is displayed in an imaged mode, all components defined by the system and the hierarchical relation among the components can be seen clearly, the components are drawnin a figure form, and therefore correctness of the define file can be verified without products; attribute setting during component running is supported, and by means of interconnection with the system, product functions and performance are tested comprehensively. The cabin display system testing method completely conforms to ARIINC 661 standard, the current situation that the cabin display system testing method based on the ARIINC 661 standard only depends system integration tests to conduct verification, and system integration tests cannot expose all abnormal current situations; meanwhile,the cabin display system testing method is capable of supporting system debugging and fault locating and effectively improving system quality and has popularization and application value.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

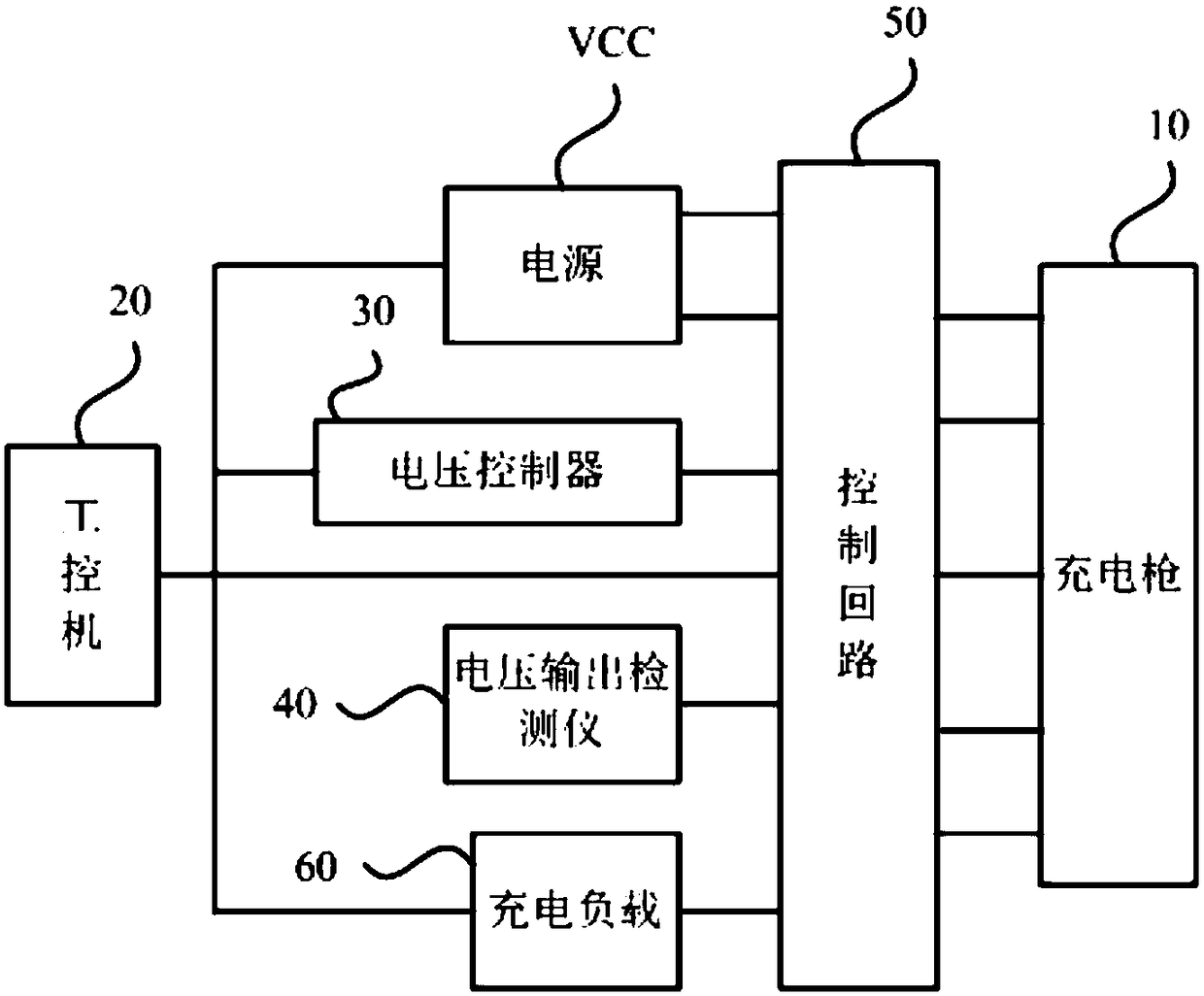

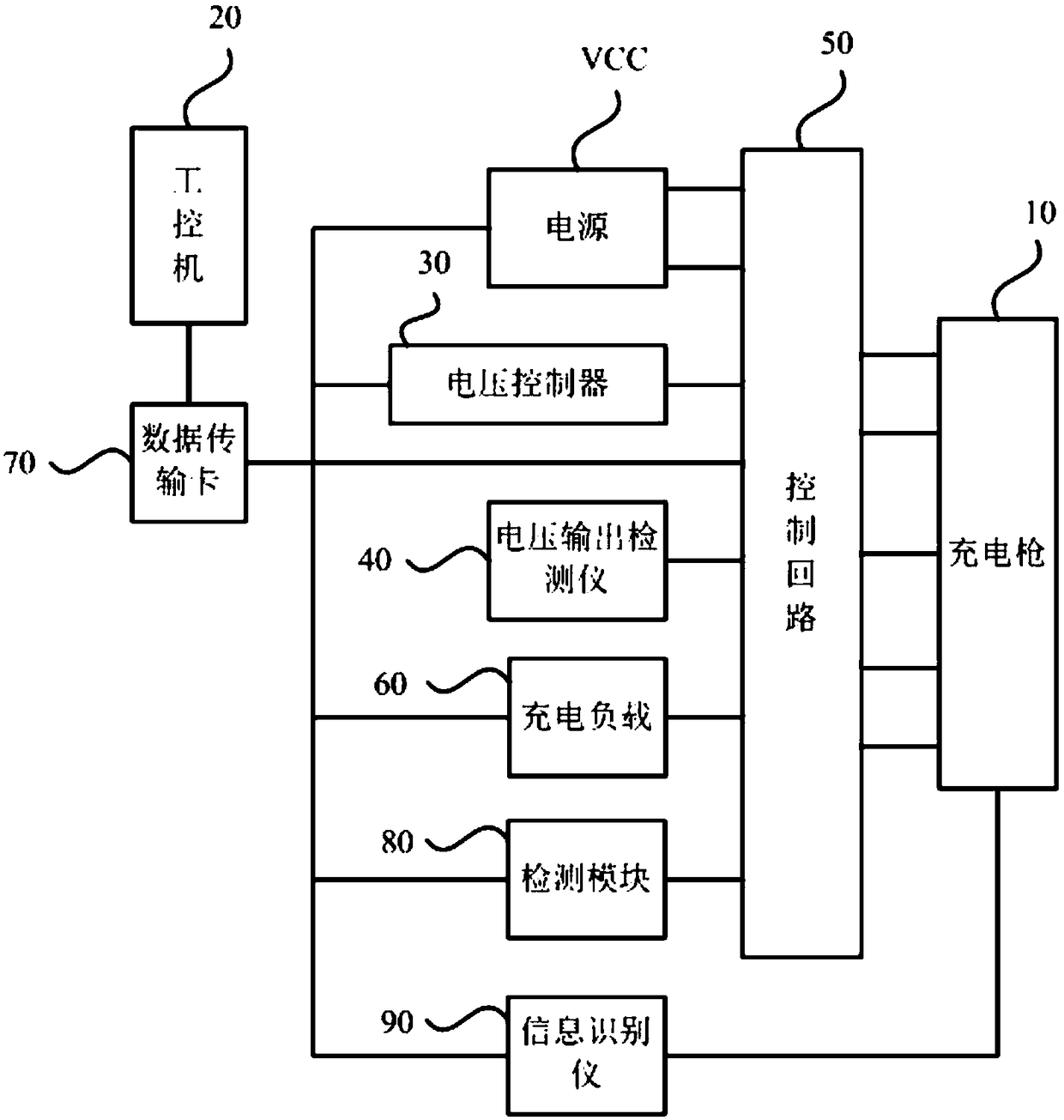

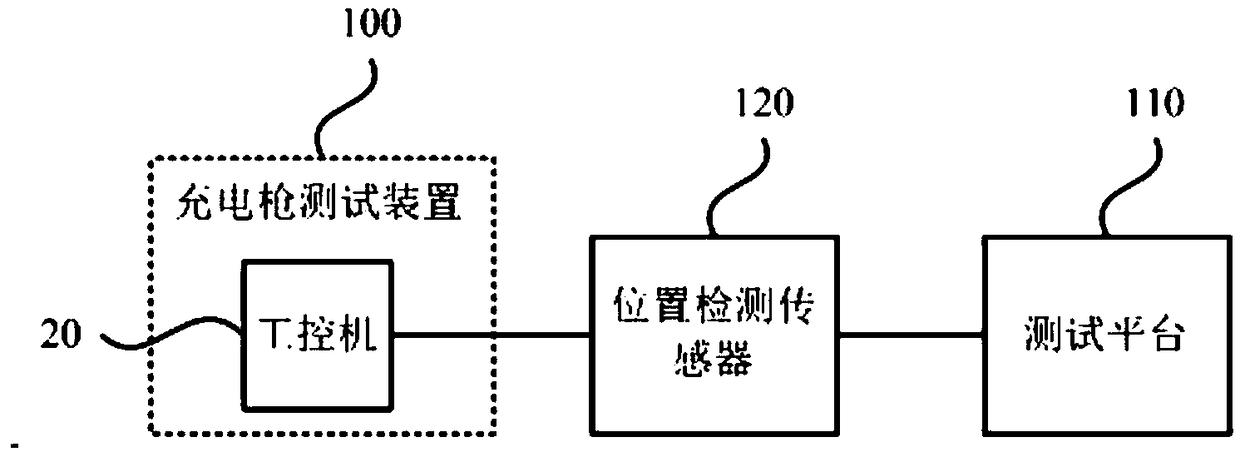

Charge gun test device and system

PendingCN108802530AAutomation reachesComprehensive testElectrical testingControl signalPersonal computer

An embodiment of the invention discloses a charge gun test device and system. The charge gun test device provides an electrical signal for a charge gun through a power source; an industrial personal computer is used to send out a control signal to control make and break of a control loop; a voltage controller, a voltage output detector and a charge load are connected with the charge gun; corresponding tests are carried out; test results of each test are fed back into the industrial personal computer for displaying and storage. The charge gun test device and system provided herein have the advantages that a charge gun under test, the voltage controller for test, the voltage output detector and the charge load can be controlled through the industrial personal computer in conjunction with thecontrol loop; the charge gun's charging service condition and output voltage condition under different voltages can be detected; therefore, automated full testing is achieved.

Owner:TESTRON SUZHOU ELECTRONICS

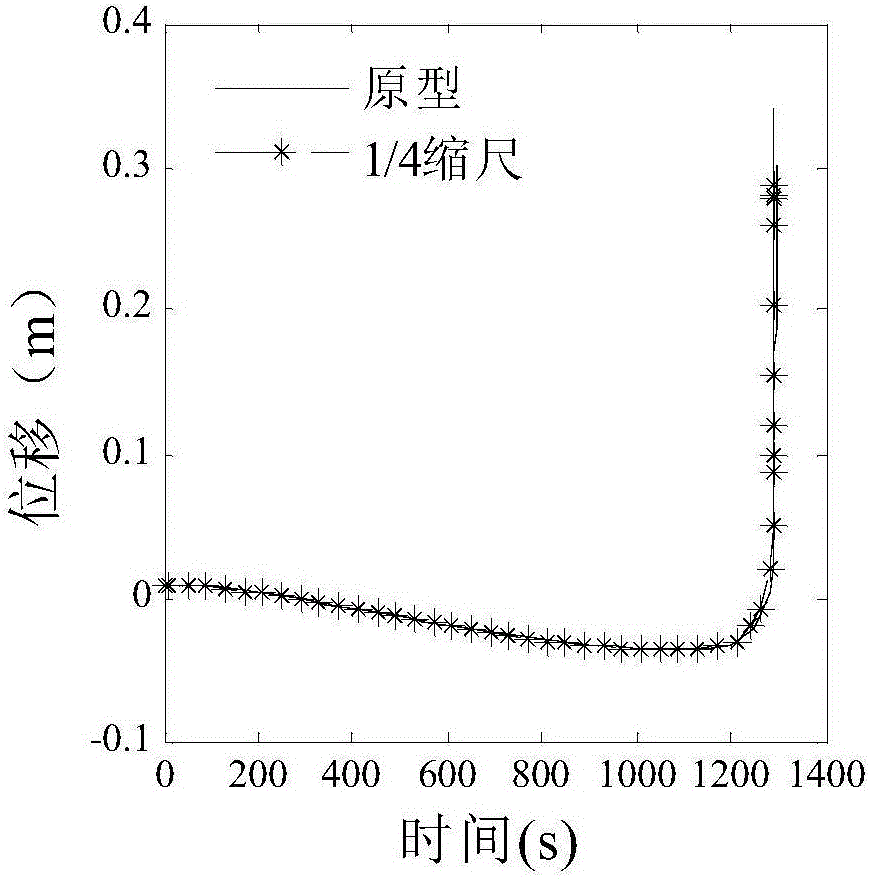

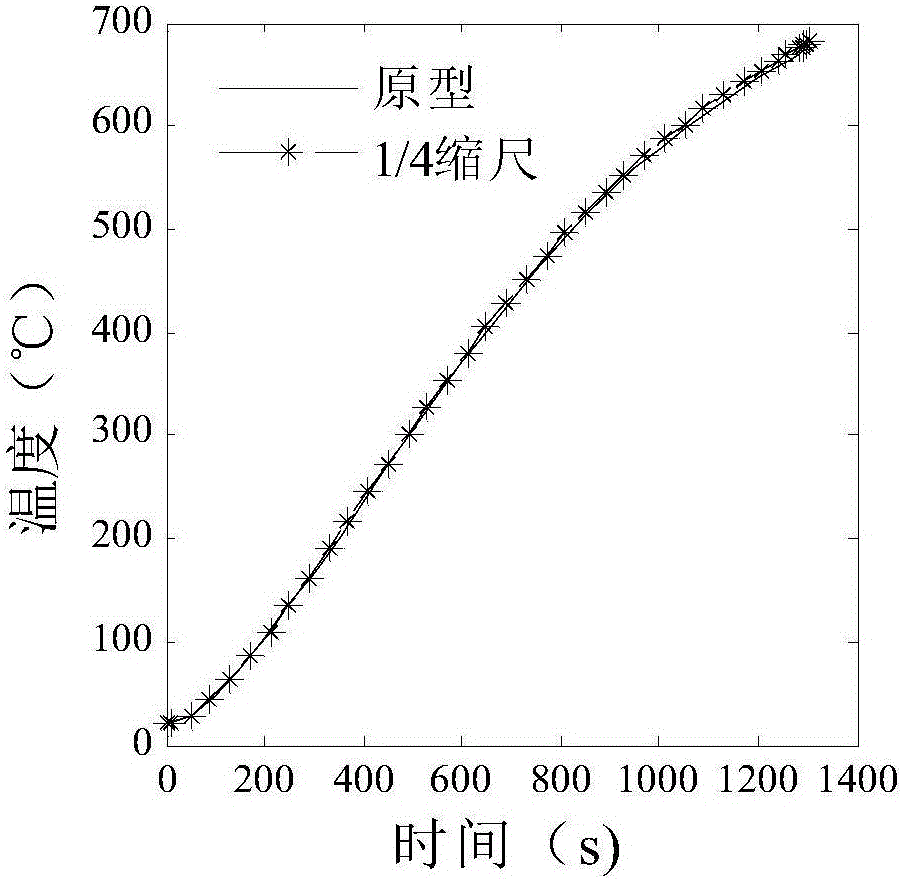

Steel structure fire response analysis method

ActiveCN106096114AAccurately reflectAccurate researchSpecial data processing applicationsScale modelPattern recognition

The invention discloses a steel structure fire response analysis method and belongs to the technical field of engineering structure fire-resistant analysis. The method comprises the steps of a, determining a fire scene similarity relationship, wherein the fire scene similarity relationship at least comprises a geometric similarity ratio; b, determining a structure similarity relationship of a steel structure according to the fire scene similarity relationship, wherein the structure similarity relationship at least comprises a surface force similarity ratio, a volume force similarity ratio, a concentrated load similarity ratio and a structure temperature similarity ratio; c, determining a heat transfer similarity relationship of the steel structure according to the fire scene similarity relationship; d, establishing a reduced scale model according to the fire scene similarity relationship, the structure similarity relationship and the heat transfer similarity relationship; e, performing a fire test on the reduced scale model; and f, performing analysis according to a fire test result of the reduced scale model, the fire scene similarity relationship, the structure similarity relationship and the heat transfer similarity relationship to obtain a fire response condition of a steel structure. According to the analysis method, the fire response condition of the steel structure can be reflected more truly and accurately, the operation is simple, and the limitation of a full-scale test is avoided.

Owner:STATE NUCLEAR ELECTRIC POWER PLANNING DESIGN & RES INST CO LTD +1

A method and system for automatic testing of electric vehicle charging facilities

ActiveCN103257286BMeet the requirements of testing specificationsEasy maintenanceElectrical testingEngineeringPerformance index

Owner:STATE GRID CORP OF CHINA +1

Self-balancing structure for bend shear test in plane of steel plate concrete wall, and manufacturing method of structure

ActiveCN109060508ASolve the problem that the in-plane bending and shearing full-scale test of the steel plate concrete wall cannot be completedMaterial strength using steady shearing forcesEngineeringFull scale test

The invention provides a self-balancing structure for a bend shear test in the plane of a steel plate concrete wall. The self-balancing structure comprises steel-encased concrete wall sections; and the steel-encased concrete wall sections include an anchorage wall section, a test wall section and a reaction wall section. According to the self-balancing structure for the bend shear test in the plane of the steel plate concrete wall provided by the invention, the self-balancing structure is formed by utilizing a characteristic that the bearing capacity in the plane of a steel plate concrete wallbody is large; bearing reaction force and anchorage needed during loading can be effectively provided; and the difficult problem that the bend shear full-scale test in the plane of the steel plate concrete wall cannot be finished by utilizing a reaction wall system and a self-balancing reaction frame is solved.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

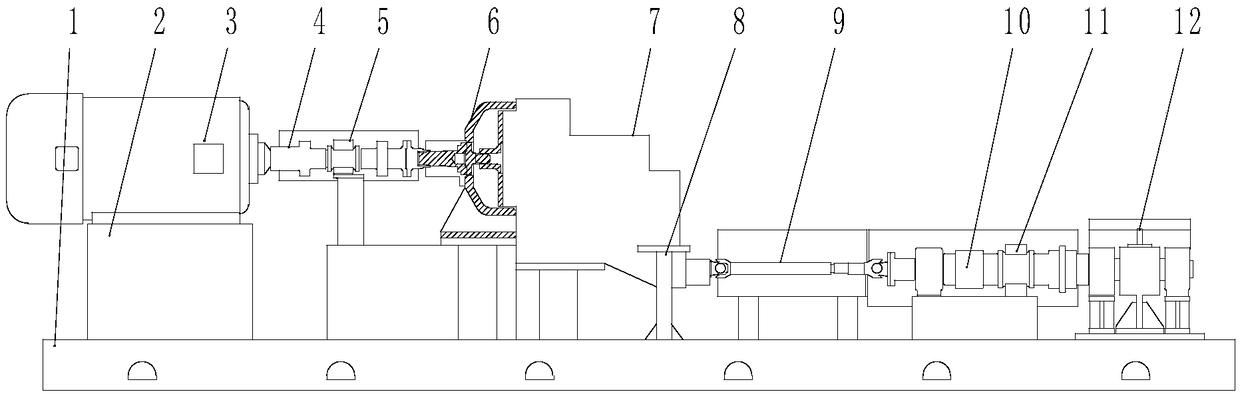

Gear box on-line comprehensive performance test method

InactiveCN109187011ALow costMeet the design requirementsMachine part testingComputer control systemCoupling

The present invention discloses a gear box on-line comprehensive performance test method, pertaining to the field of engineering machinery. According to the method, all performance indexes, such as the gear-shifting pressure, the lubrication pressure, the gear-shifting oil-way tightness, the torque converter oil pressure, the output torque and the output rotational speed, of the gear box are tested via an on-line comprehensive performance test table. The on-line comprehensive performance test table comprises a test table body, a hydraulic system and a computer control system. The test table body is fixedly provided with a drive motor, a coupling A, a coupling B and a braking system. The drive motor is connected with the input end of the coupling A, the input end of the coupling B is connected with a transmission shaft, and the output end of the coupling B is connected with the braking system. The coupling A and the coupling B are separately provided with an input torque and rotationalspeed sensor and an output torque and rotational speed sensor. The method can perform comprehensive test on the performance indexes of the gear box and ensure the 100% one-time delivery qualified rateof the performance of the gear box, and the in-plant commissioning and repairing cost and the market failure maintenance cost of the gear box are reduced.

Owner:SHANDONG LINGONG CONSTR MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com