Loading device and method for shield tunnel lining ring full-scale test

A shield tunneling and loading device technology, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of inability to simulate bias pressure, local resistance changes, inability to simulate passive resistance of soil, Problems such as the inability to realize the simultaneous change of loads, etc., achieve the effect of wide applicability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

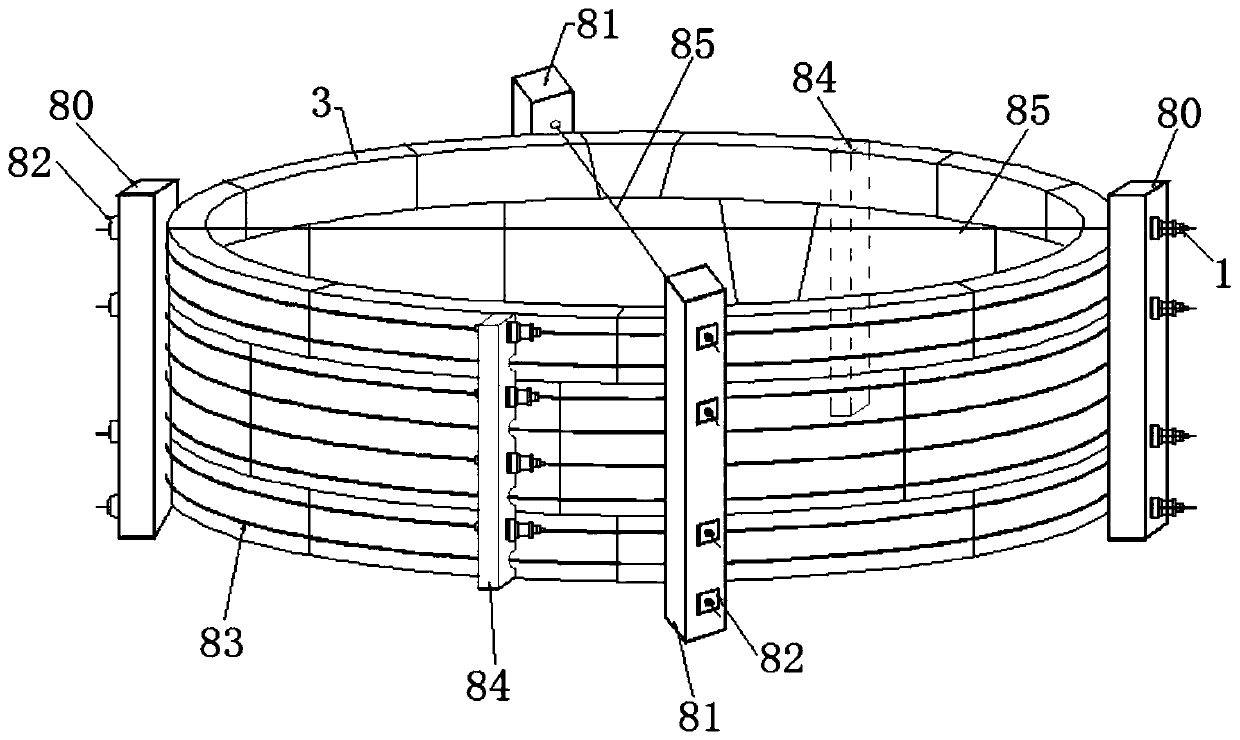

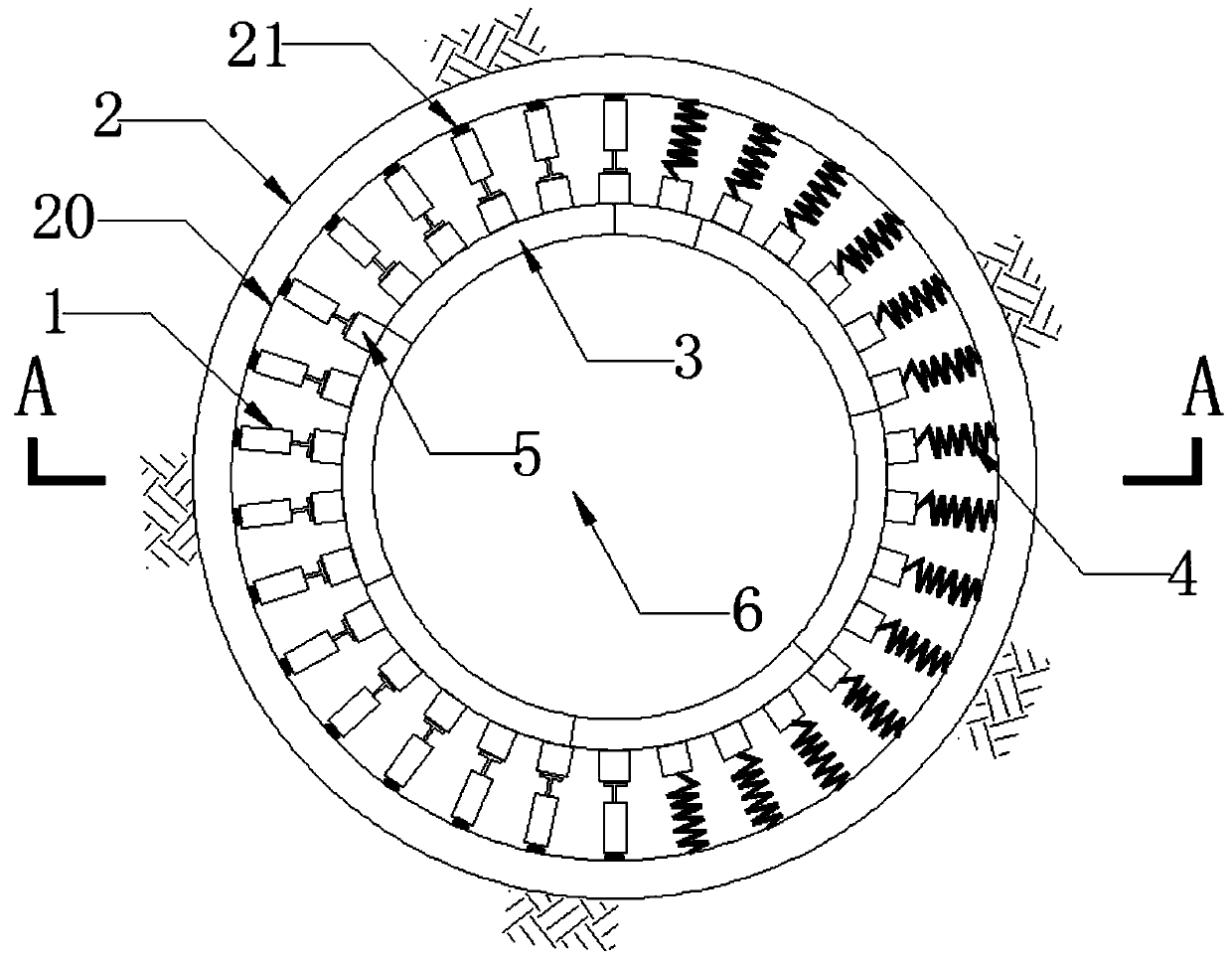

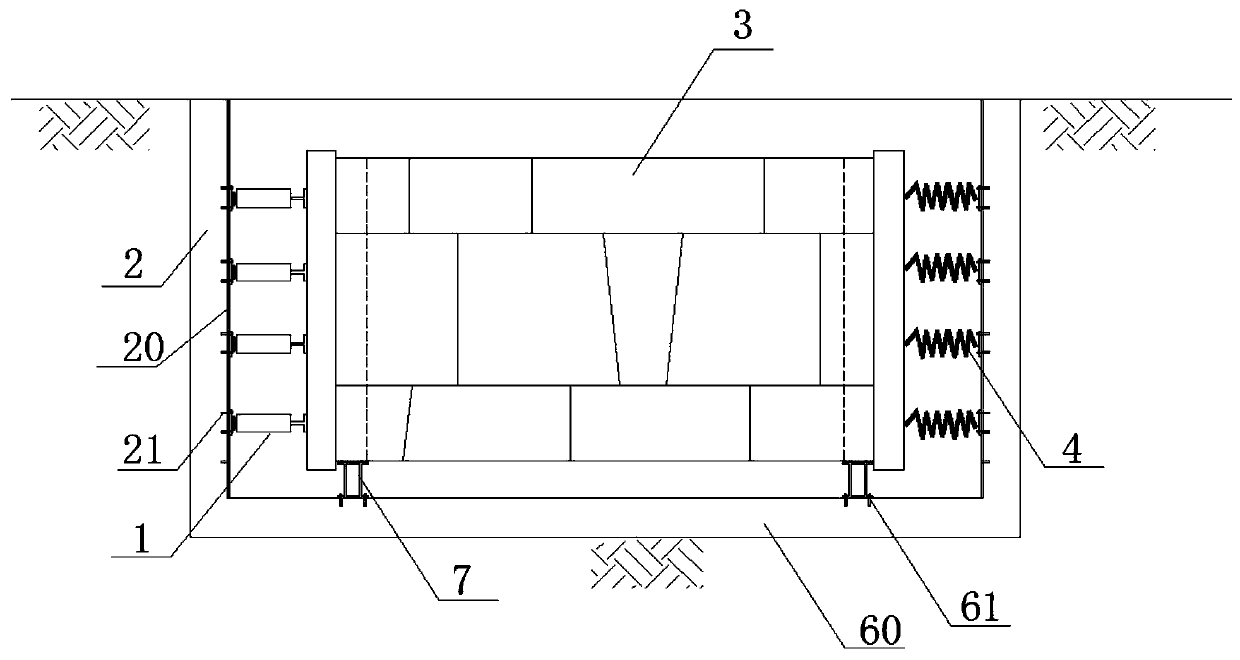

[0033] see Figure 2-5 , the embodiment of the present invention provides a shield tunnel lining ring full-scale test loading device, including a jack 1 for applying force, a resistance spring 4, and an annular reaction wall 2. Wherein, the reaction wall 2 has a test area for placing the ring-shaped test segment 3, one end of the jack 1 and one end of the resistance spring 4 are installed on the reaction wall 2, The other end of the jack 1 and the other end of the resistance spring 4 both act on the test tube piece 3 . In the existing technology, such as figure 1 As shown, in the loading test of the test segment 3, the ring of the shield tunnel test segment 3 is usually placed parallel to the horizontal ground, that is, multiple test segments 3 are piled up, and then a pair of main and paired pulleys are arranged outside the ring. Beam 80 and a pair of secondary tension beams 81, and between two main tension beams 80 and between two secondary tension beams 81, tension anchor...

Embodiment 2

[0044] see Figure 2-5 , an embodiment of the present invention provides a full-scale test loading method for a shield tunnel lining ring, including the following steps: S1, excavating an annular foundation pit downward on the ground, and using the side wall of the foundation pit as a reaction wall 2; S2, placing the ring-shaped test segment 3 to be tested in the foundation pit; S3, using a jack 1 and a resistance spring 4 between the reaction wall 2 and the test segment 3, and placing the One end of the jack 1 and one end of the resistance spring 4 are installed on the reaction wall 2, and the other end of the jack 1 and the other end of the resistance spring 4 act on the test segment 3 on. In this embodiment, a ring-shaped foundation pit is excavated below the ground, and then the side wall of the foundation pit is poured with reinforced concrete to obtain the reaction wall 2, and at the same time, reinforced concrete is poured at the bottom to make the floor 6, and the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com