Gear box on-line comprehensive performance test method

A comprehensive performance testing and comprehensive performance technology, applied in the testing of mechanical components, the testing of machine/structural components, measuring devices, etc., can solve the problem of inability to detect the performance of gearboxes, and reduce the cost of maintenance and repair in the market. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

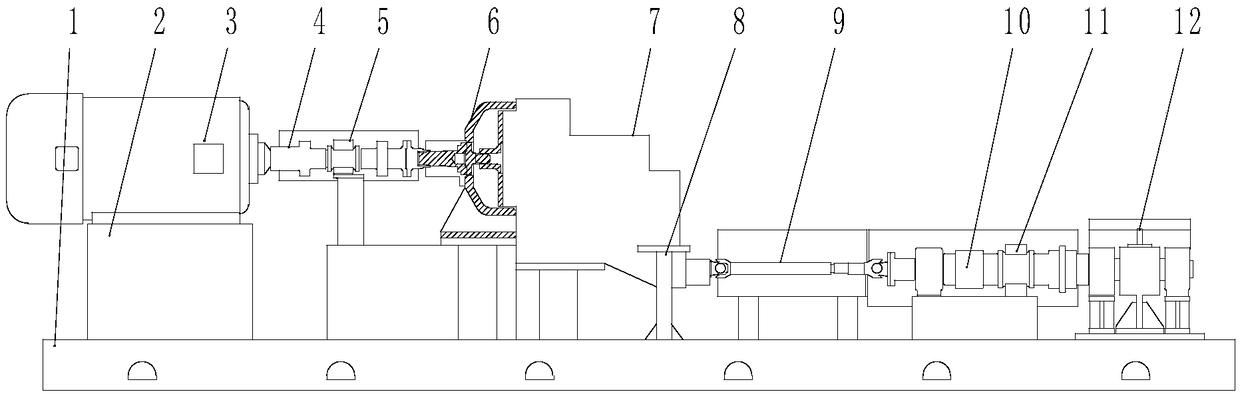

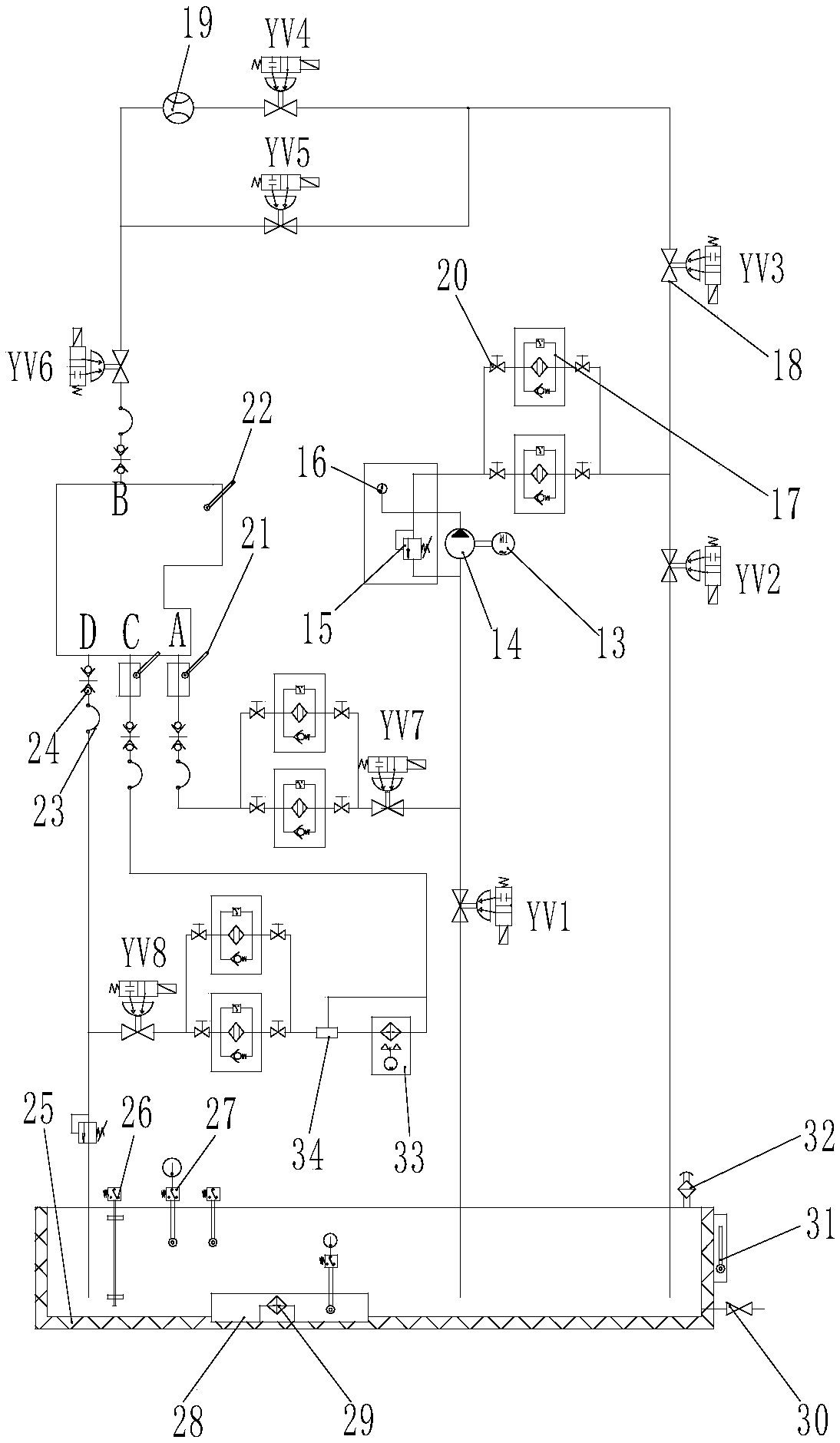

[0022] Such as figure 1 As shown, the online comprehensive performance testing method of the gearbox described in the present invention detects various performance indicators of the gearbox 7 through the online comprehensive performance test bench. The online comprehensive performance test bench includes a test bench body 1, a hydraulic system and a computer control system, the test bench body 1 is fixed with a drive motor support 2, a drive motor 3, a coupling A4, a front support 6, a rear support 8, a coupling B10 and a braking system 12, and a drive motor support 2 The driving motor 3 is fixedly installed on the top, and the driving motor 3 is a three-phase asynchronous motor with variable frequency speed regulation, which is used to simulate various working conditions of the test piece. The input shaft of the box 7, the front support 6 and the rear support 8 are used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com