Reflow welding process simulation model correction method based on measured temperature data

A simulation model and welding process technology, which is applied in the field of reflow soldering process simulation model correction based on measured temperature data, can solve the problem of inaccurate simulation of reflow soldering process temperature field model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

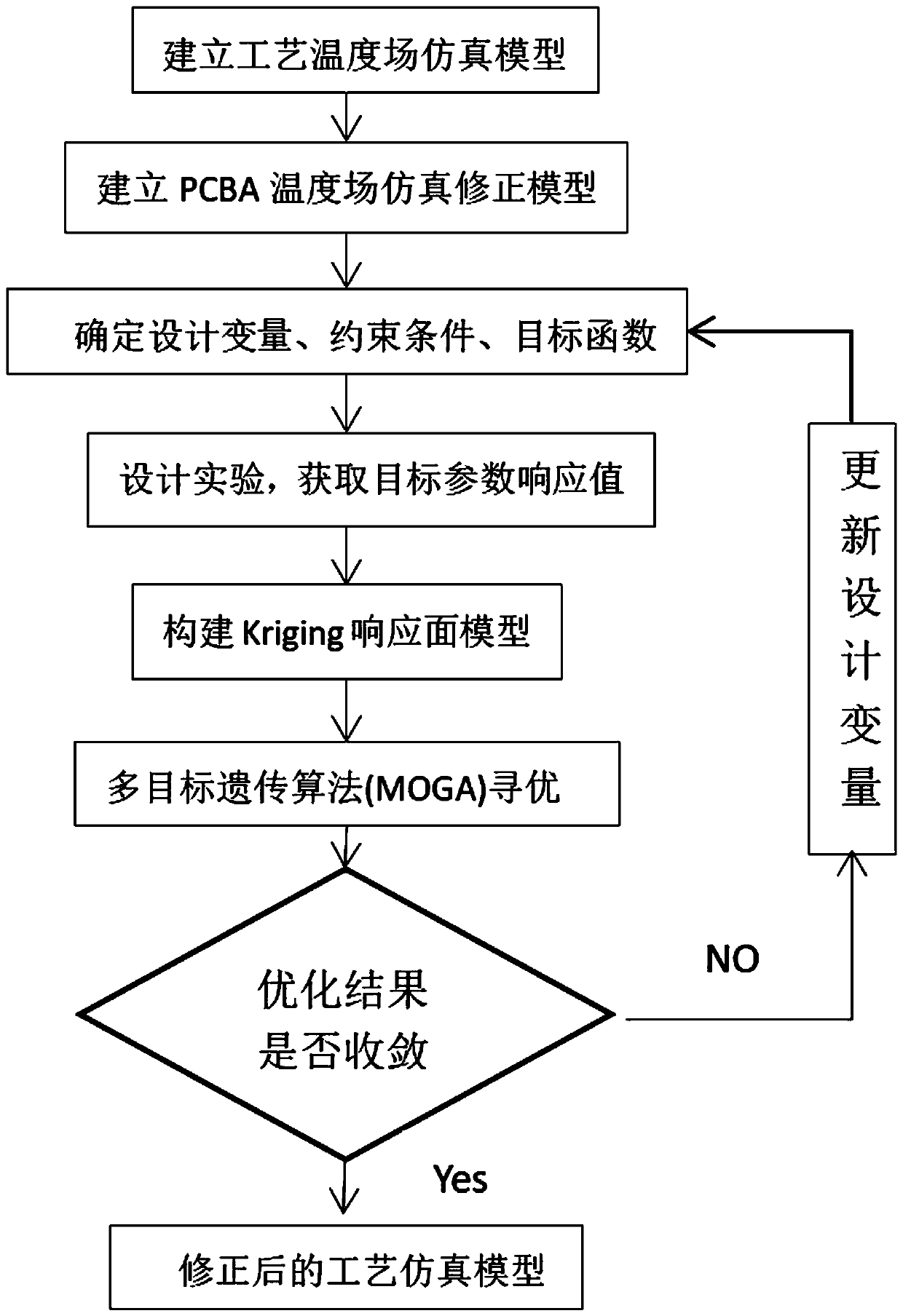

[0018] Such as figure 1 As shown, a reflow soldering process simulation model correction method based on measured temperature data includes the following steps:

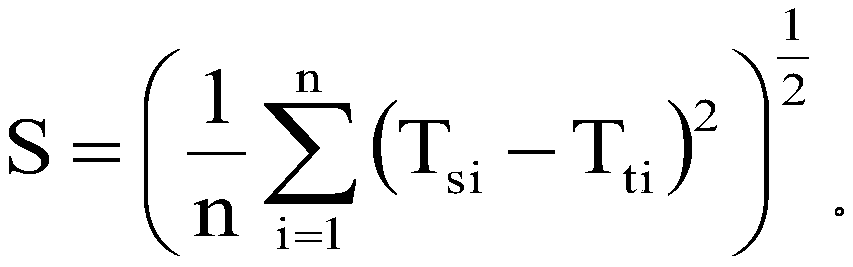

[0019] Step 1. Establish a simulation model of the reflow soldering process temperature field, use transient thermal simulation analysis to obtain the simulation temperature curve of the solder joint, take the actual temperature curve as the standard, and use the simulation curve as the input to calculate the standard deviation (S) of the corresponding node temperature;

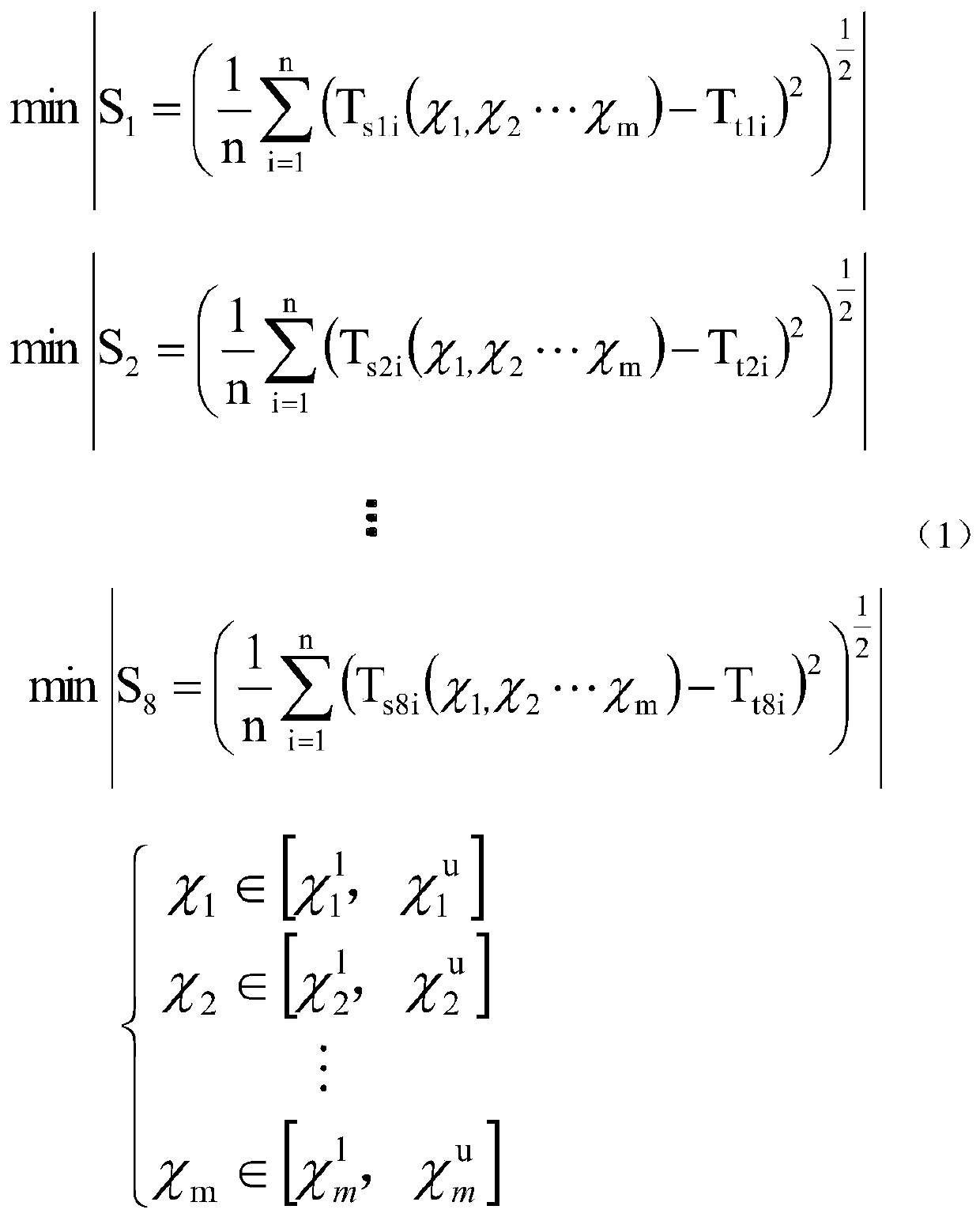

[0020] Step 2, determine the design parameters, constraints, and objective functions, and establish a PCBA temperature field simulation correction model;

[0021] Step 3, design the experiment, obtain the response value of the target parameter; sample the modified design parameters, and then bring the sampled sample points into the process simulation model before correction, and calculate the target parameter response value of the process parameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com