Elevator door guide shoe abrasion testing device and method

A testing device and elevator door technology, applied in the elevator field, can solve the problems of increased development cost, time-consuming and labor-intensive, inability to accurately adjust the pressure value of door guide shoes, etc., and achieve the effect of saving development cost and shortening development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

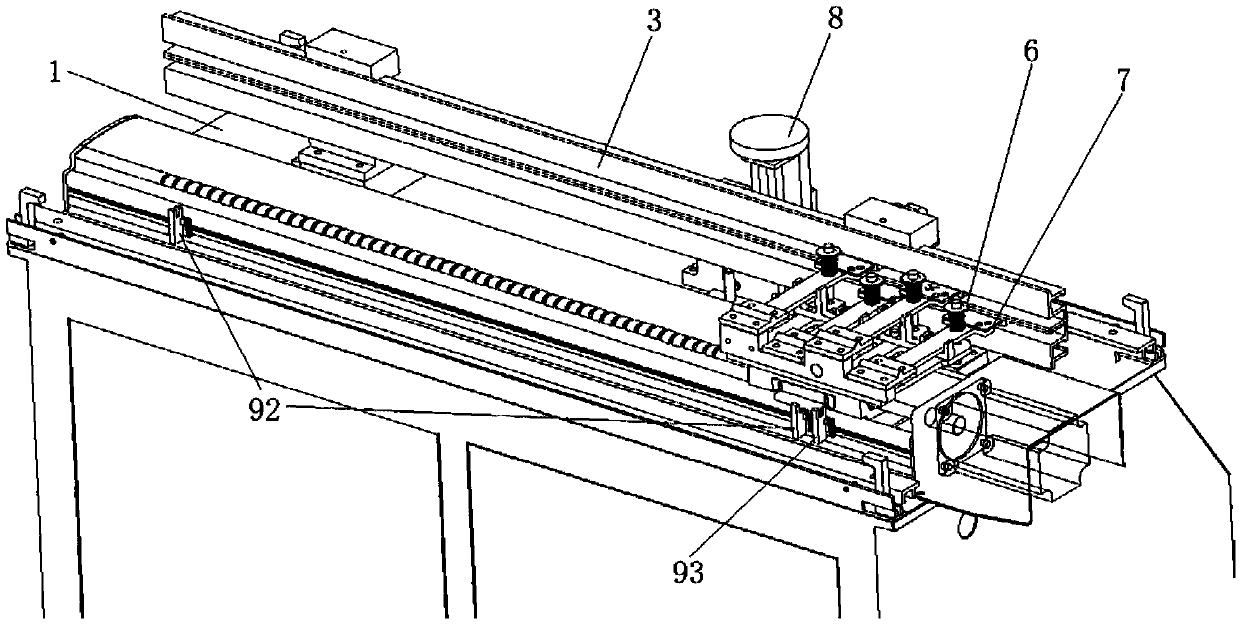

[0057] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the elevator door guide shoe wear test device includes a workbench 1, a linear guide rail 2, an elevator sill 3, a ball screw pair 4, a mounting seat 5, and a pressure adjustment device 6;

[0058] The linear guide rail 2, the ball screw pair 4, and the elevator sill 3 are sequentially fixed on the top of the workbench 1 from back to front;

[0059] The direction of the linear guide rail 2 and the elevator sill 3 are all parallel to the screw axis of the ball screw pair 4;

[0060] The elevator sill 3 can move back and forth;

[0061] The screw of the ball screw pair 4 can rotate along its axis;

[0062] The middle part of the mounting seat 5 is fixed on the nut of the ball screw pair 4;

[0063] The lower part of the rear part of the mounting base 5 abuts against the upper surface of the linear guide rail 2;

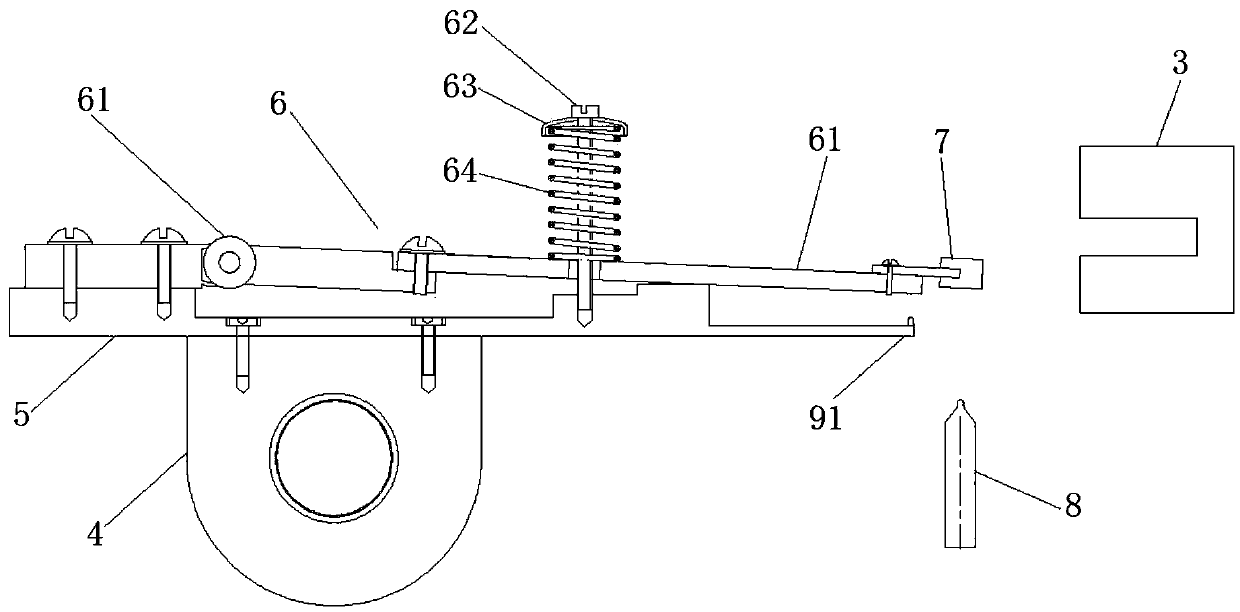

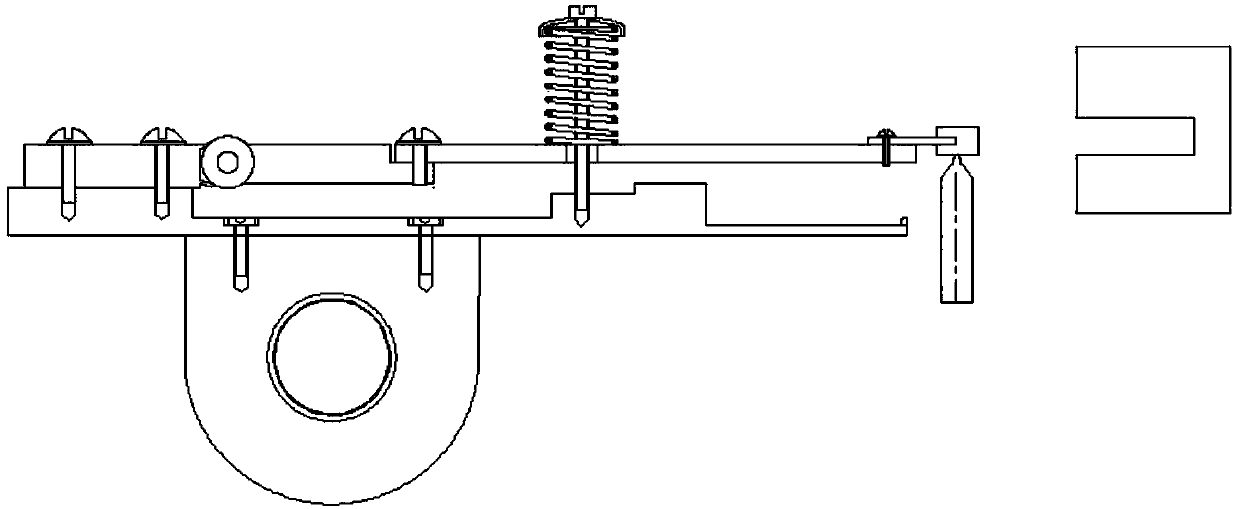

[0064] The pressure adjusting device 6 includes a connecting rod 61, a screw 62...

Embodiment 2

[0074] Based on the first embodiment, the elevator door guide shoe wear test device also includes a force measuring device 8;

[0075] The force measuring device 8 includes a pressure sensor and its driving guide; the driving guide is fixed on the workbench 1;

[0076] The pressure sensor can be extended toward the front end of the connecting rod 61 or retracted toward the workbench 1 under the driving of the driving guide device.

[0077] In the elevator door guide shoe wear test device of the second embodiment, the driving and guiding device of the force measuring device 8 can drive the probe of the pressure sensor to move and withstand the door guide shoe 7 fixed at the front end of the connecting rod when force measurement is required. After the force is completed, the pressure sensor probe is driven back to its original position by the driving guide device, which will not block the backward movement of the elevator sill 3, so that the elevator sill 3 moves backward so tha...

Embodiment 3

[0079] Based on the second embodiment, the elevator door guide shoe wear test device also includes a laser ranging sensor 90;

[0080] The laser ranging sensor 90 is used to detect the thickness of the door guide shoe 7 fixed on the front end of the connecting rod 61 .

[0081] Preferably, the screw hole at the front of the mounting seat 5 is a boss;

[0082] The front end of the mounting seat 5 is located directly below the front end of the connecting rod;

[0083] The laser ranging sensor is arranged at the front end of the mounting base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com