High-rise building cable vertical shaft structure

A technology for cable shafts and high-rise buildings, applied to building components, building structures, buildings, etc., can solve problems such as hidden safety hazards in cable shafts, insufficient cable layout structures, etc., to prevent diffusion, reduce the speed of smoke diffusion, and ensure heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

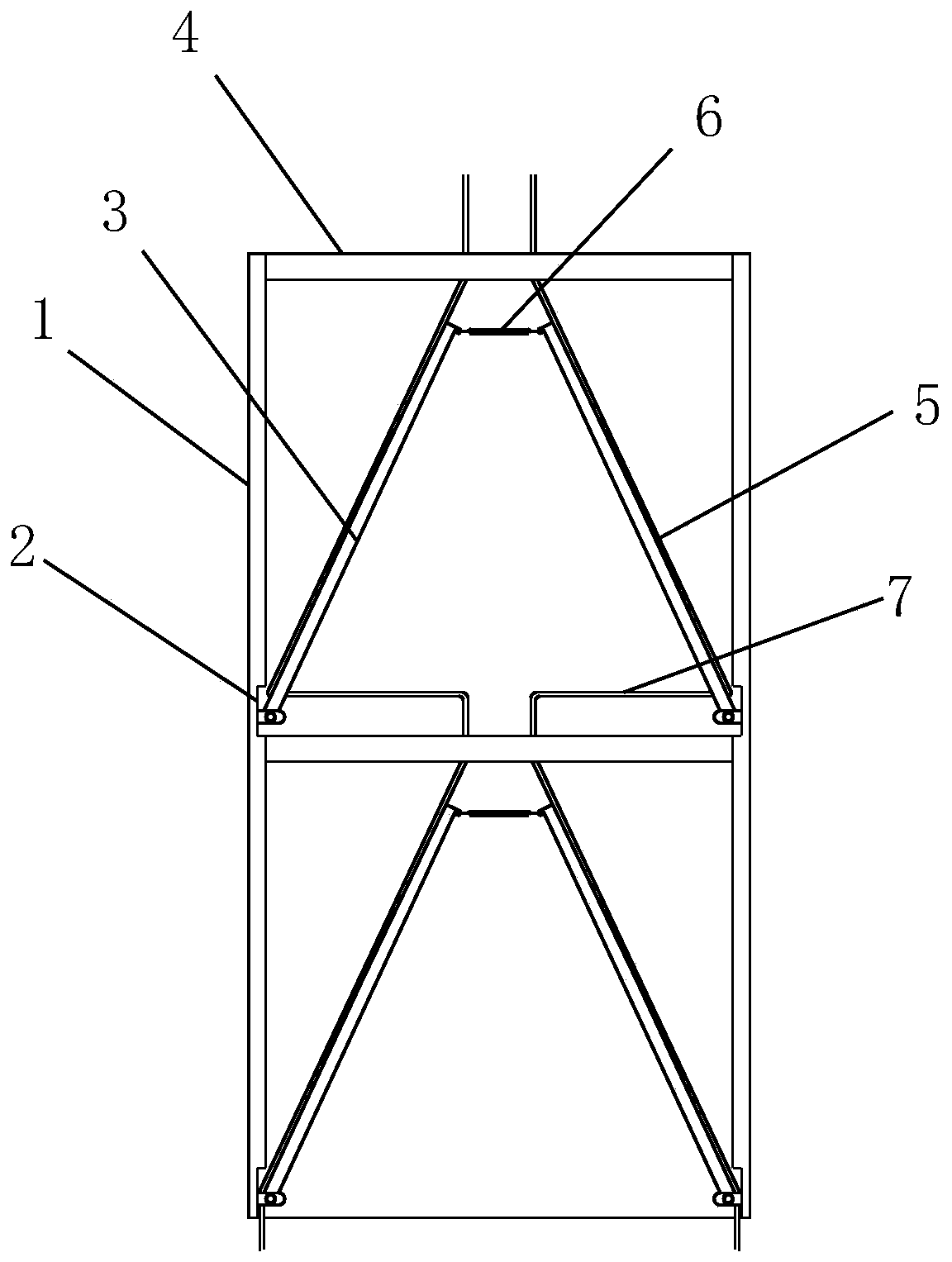

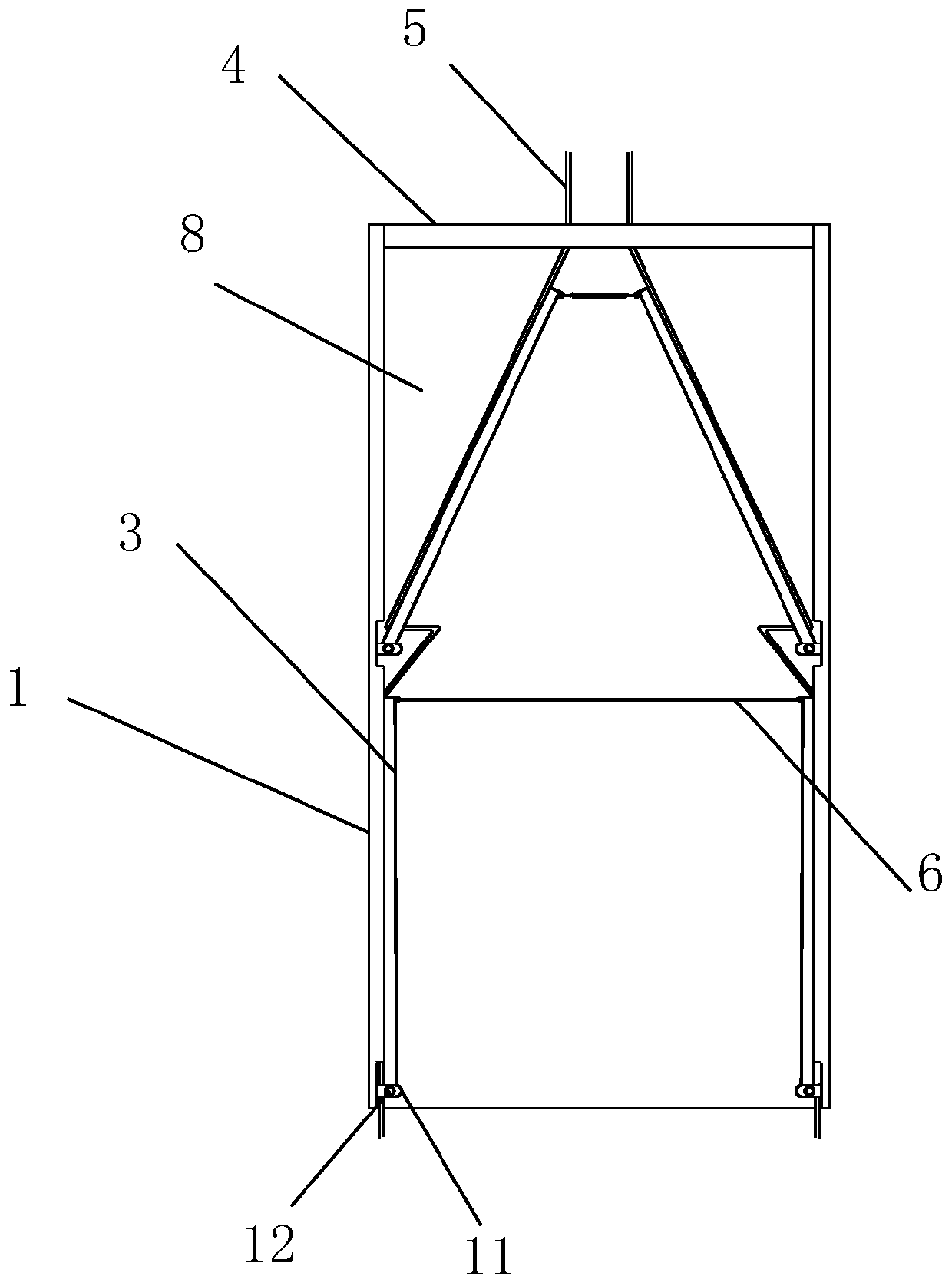

[0021] Such as figure 1 As shown, the cable shaft structure of this high-rise building includes a shaft 1. There is a shaft cavity 8 penetrating up and down in the shaft 1. A notch 2 is opened in the shaft cavity 8 facing each floor, and the notch 2 is opened in the shaft cavity 8. On both sides of the inner wall of the notch 2, a connecting ear 11 is vertically arranged on both sides of the bottom surface of the notch 2, and a sealing plate 3 is elastically hinged between two adjacent connecting ears 11, and the sealing plate 3 is fixedly arranged with more than one side of the shaft cavity. The cable 5 is provided with a corresponding cable groove (not shown) on the inner wall of the shaft cavity 8 facing each cable 5. When the sealing plate 3 is reset, the cable 5 is buckled into the corresponding cable groove;

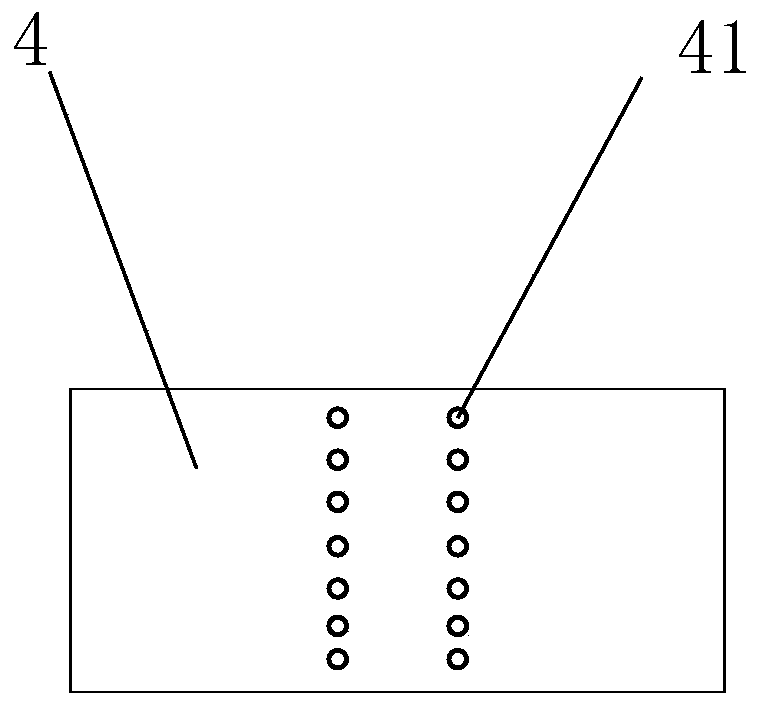

[0022] A layer of fireproof layer 4 is installed in the shaft cavity corresponding to each layer of building body. The width of the fireproof layer is smaller than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com