Sheath connecting structure of combined cables

A technology of combining cables and connecting structures, applied in electrical components and other directions, can solve problems such as inconvenience in operation, and achieve the effect of avoiding water infiltration and working environment safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

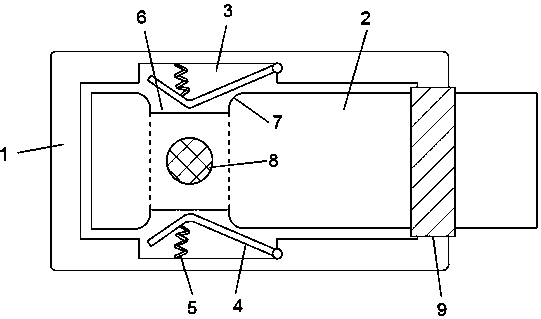

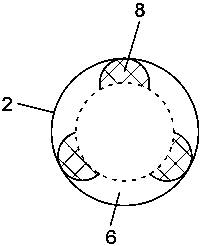

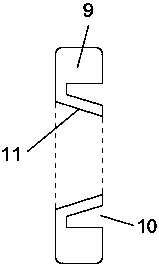

[0019] refer to Figure 1-3 , the sheath connection structure of the combined cable, including an outer jacket 1, an inner sleeve 2 is inserted in the outer jacket 1, an annular groove 3 is opened on the inner wall of the outer jacket 1, and a plurality of contact rods 4 are rotatably connected on the inner wall of the annular groove 1 3 , a compression spring 5 is fixedly connected between each contact rod 4 and the inner wall of the annular groove 1, and an annular groove 2 6 is provided on the outer wall of the inner sleeve 2. Further description, when the contact rod 4 snaps into the annular groove 2 6 When the compression spring 5 is not fully expanded in the interior, the inner cover 2 is fixed by the elastic force that is provided, and a plurality of semicircle blocks 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com