Stacking plate for a stacked plate heat exchanger and a stacked plate heat exchanger

A technology of heat exchangers and stacked plates, applied in the direction of indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve problems such as fluid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

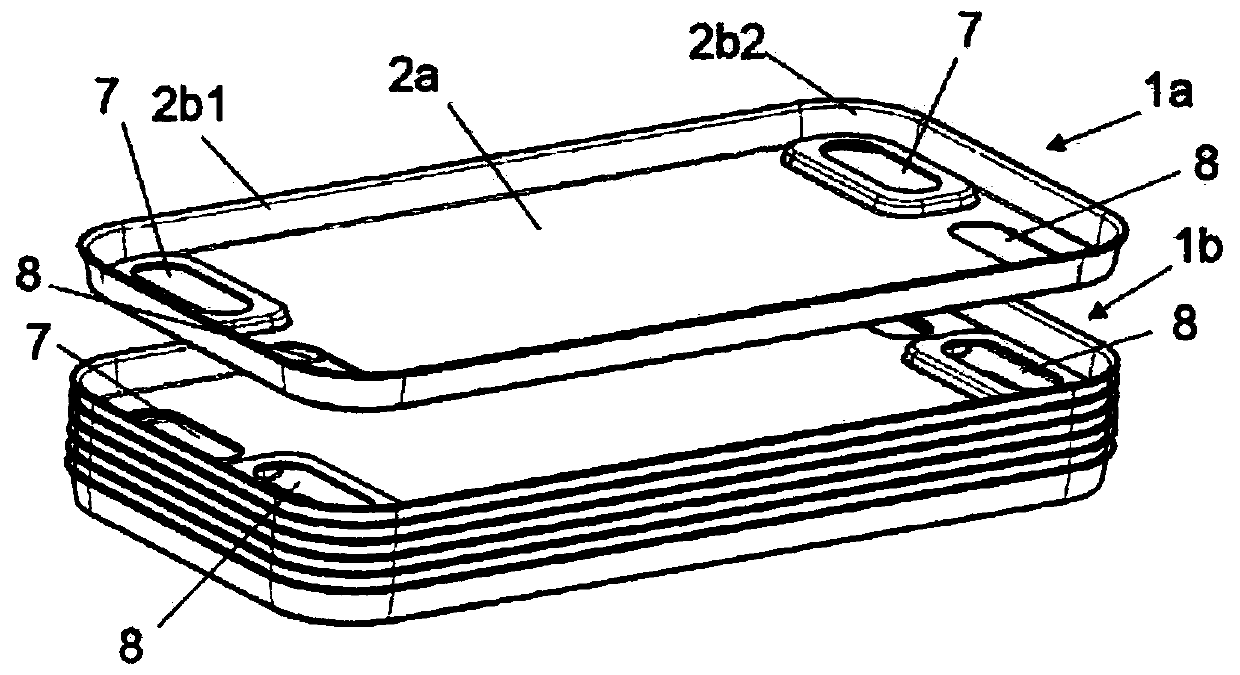

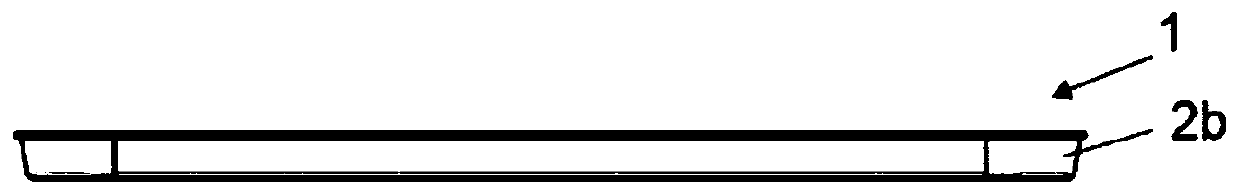

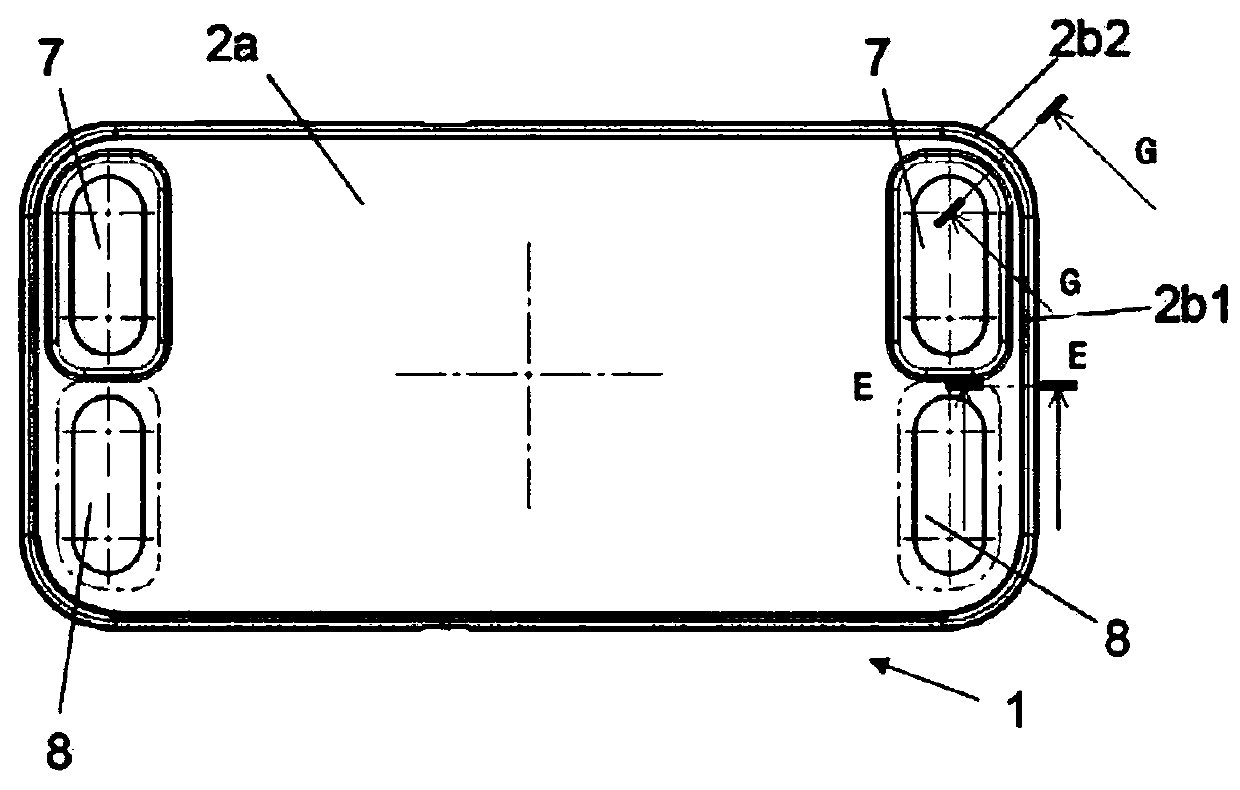

[0042] As shown in the attached figure, especially figure 1 , 2a and 2b, a stacked plate 1, 1a, 1b for a stacked plate heat exchanger according to the first aspect of the invention comprising:

[0043] - a substantially flat base 2a extending along a main plane, in which a first passage opening 7 and a second passage opening 8 are provided for passage of the first and second medium respectively, and

[0044] - A raised edge 2b, which protrudes beyond the periphery of said substantially planar base 2a, continuously surrounding it.

[0045] figure 1 Also shown is a part of a stacked plate heat exchanger according to the second aspect of the invention, in particular a plurality of stacked plates 1 comprising:

[0046] - a first stacked plate 1a, wherein the first passage opening 7 is located in the substantially planar base 2a, while the second passage opening 8 is arranged in a raised annular structure; and

[0047] - A second stacked plate 1b, wherein the second passage ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com