One time shaping method of grooved semi-axis nut

A forming method and shaft nut technology, applied in the directions of bolts, threaded fasteners, connecting components, etc., can solve problems such as multiple turnover costs, and achieve the effects of improving utilization, reducing logistics turnover costs, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

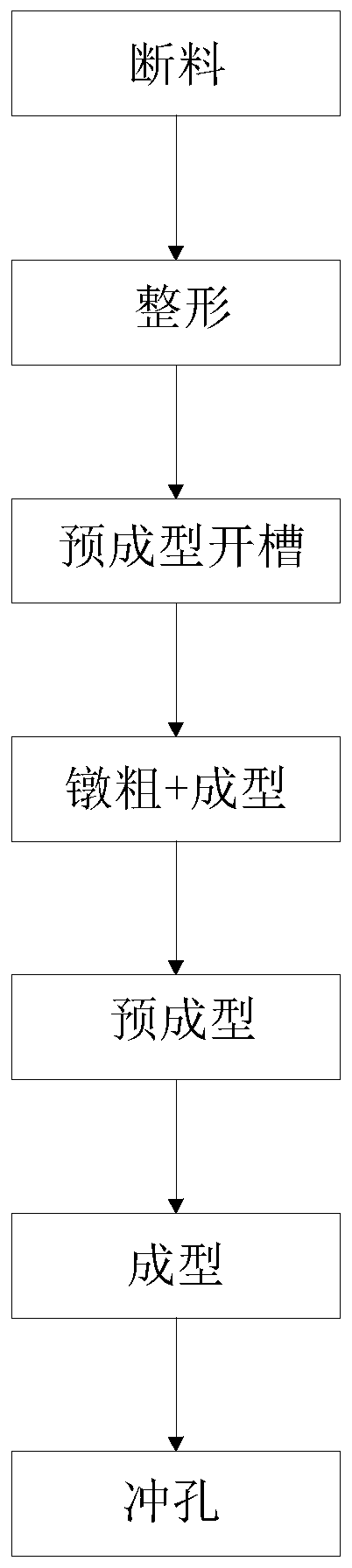

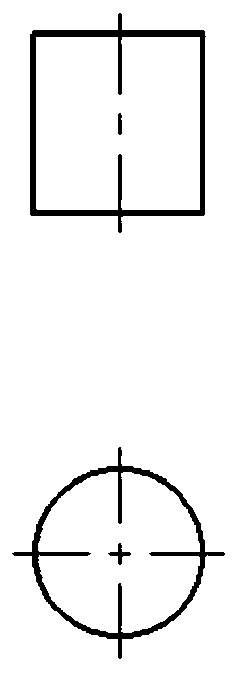

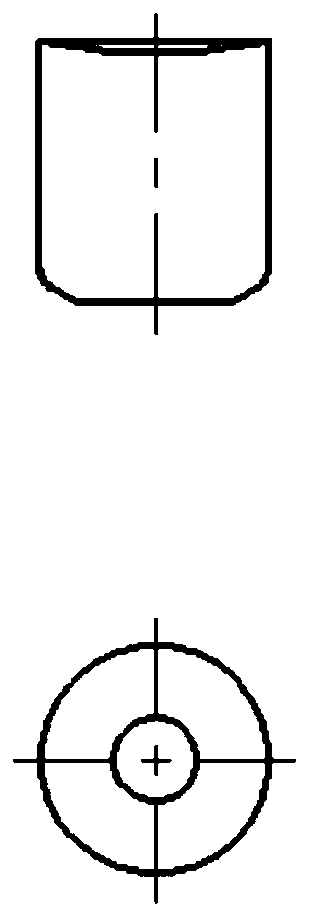

[0030] Embodiment one: if Figure 1-8 Shown:

[0031] The one-time forming method of the slotted axle nut comprises the following steps:

[0032] 1) Material cutting, the material knife and material cutting die cut the material into a specified length according to the length of the material to be formed, and then send it to the shaping die mouth;

[0033] 2) Shaping, the broken material is sent to the mouth of the shaping die, the shaping male mold punches the broken material blank into the shaping female mold, and then extrudes the blank to deform to achieve the required shaping shape and prepare for the next sequence;

[0034] 3) Preforming and slotting, and the shaped blank is sent to the opening of the slotting die by clamps;

[0035] 4) Upsetting and forming grooves, the pre-grooved blank is sent to the mouth of the upsetting die by the clamp, and the upsetting male mold punches the shaped blank into the upsetting female mold to perform upsetting and forming groove defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com