Continuous turnover device for carton packaging

A technology for packaging and cartons, which is applied in the field of continuous turning devices for carton packaging, and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

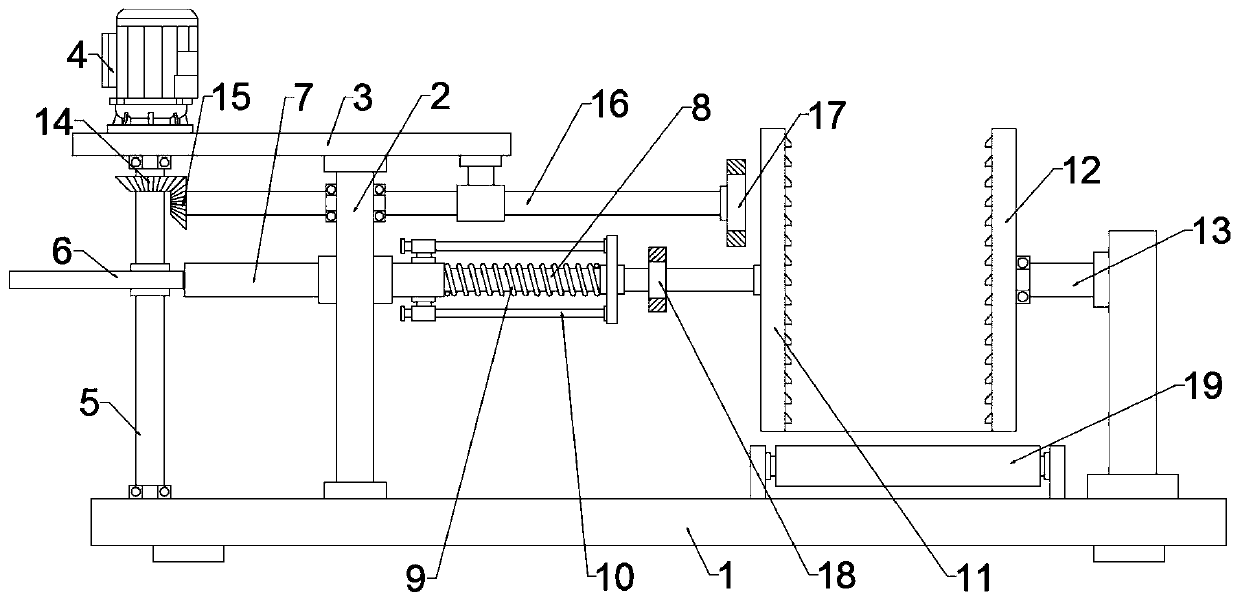

[0021] see Figure 1~3 , in an embodiment of the present invention, a continuous turning device for carton packaging, comprising a bottom plate 1, a top plate 3 fixed above the bottom plate 1 through a support plate 2, a motor 4 flanged to the top of the top plate 3, and an output connected to the output end of the motor 4 The shaft 5, the clamping assembly and the turning assembly connected to the output shaft 5, wherein the output shaft 5 passes through the top plate 3 and is connected with bearings, the lower end bearing of the output shaft 5 is connected to the bottom plate 1, and the motor 4 is electrically connected to the switch and the power supply , the power on and off of the motor 4 is controlled by a switch, and the motor 4 drives the output shaft 5 to rotate when the power is on.

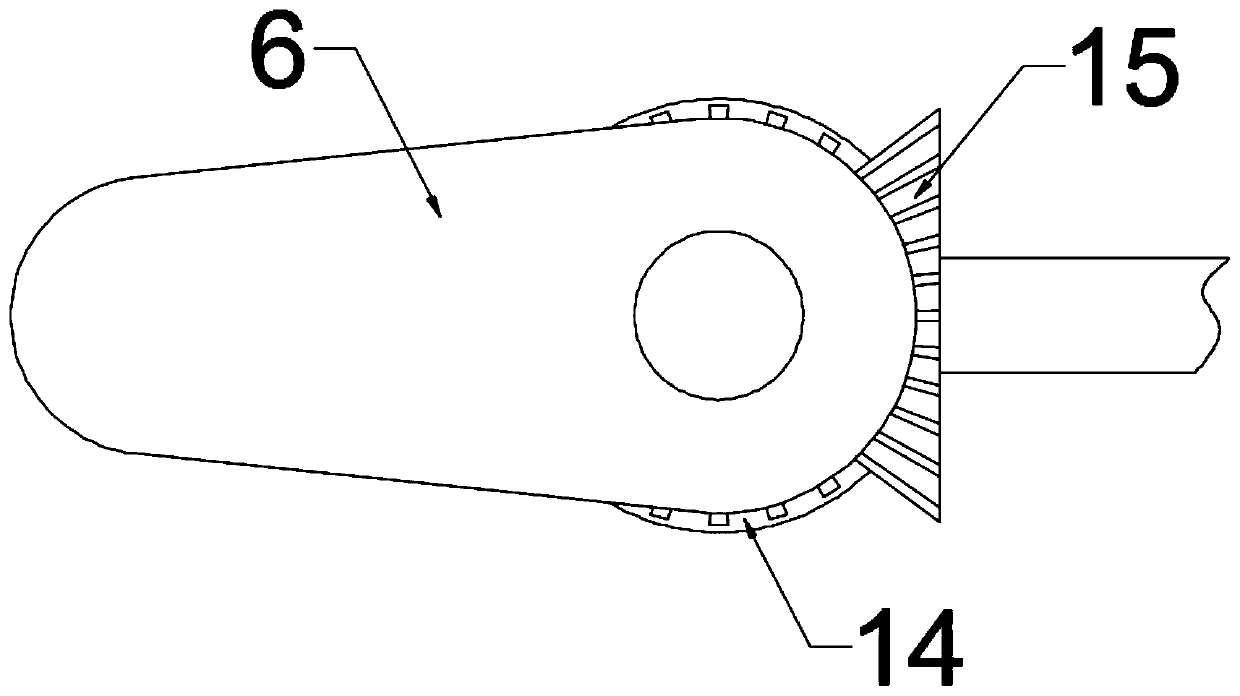

[0022] Further, the clamping assembly includes a cam 6 fixed on the output shaft 5, a moving tube 7 fitted to the cam 6, a sleeve 8 elastically connected to the moving tube 7, and a sle...

Embodiment 2

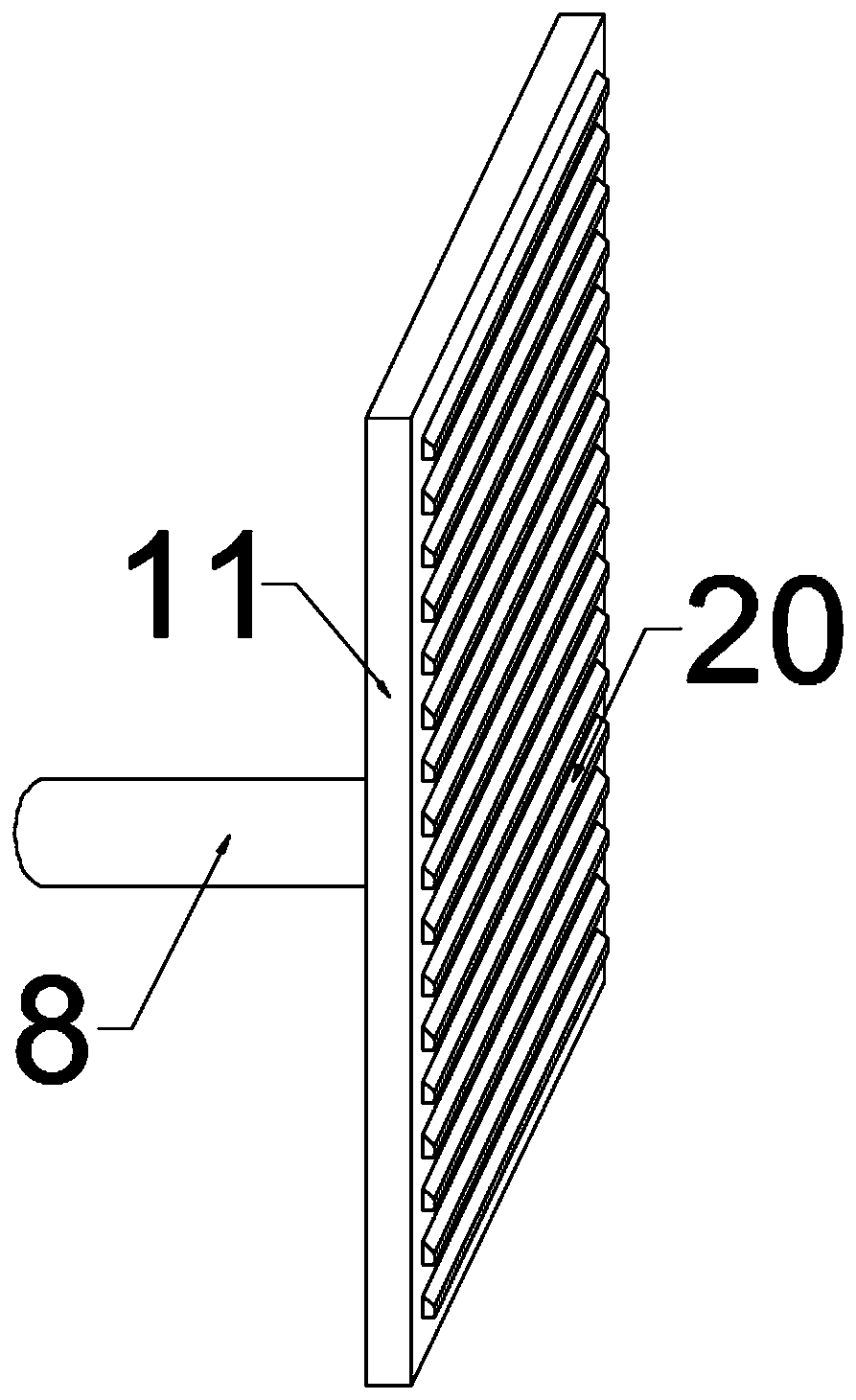

[0025] In order to further explain and further define the overturning assembly in the above embodiment, in another embodiment of the present invention, a continuous overturning device for carton packaging, the overturning assembly includes a driven The shaft 16, the large gear 17 fixed on the end of the driven shaft 16, and the pinion 18 fixed on the sleeve 8, wherein the pinion 18 is fixed on the side of the sleeve 8 relative to the moving tube 7, it should be noted that from The driving shaft 16 passes through the support plate 2 and is connected with bearings. The rotating output shaft 5 drives the driven shaft 16 to rotate through the bevel gear set, and then drives the large gear 17 to rotate. Cooperating with the cam 6 to drive the sleeve 8 to move back and forth laterally, the large gear 17 meshes with the pinion 18 to drive the clamped casing to rotate to achieve the function of overturning the casing.

[0026] In detail, the bevel gear set includes a first bevel gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com