Heating sealing device and sealing method of special packing machine for sanitary towel products

A technology of sealing device and sanitary napkin, applied in the directions of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inability to ensure neat and beautiful sealing, shifting of electric heating wires, affecting product quality, etc., to ensure that the sealing is firm, neat and beautiful, The effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

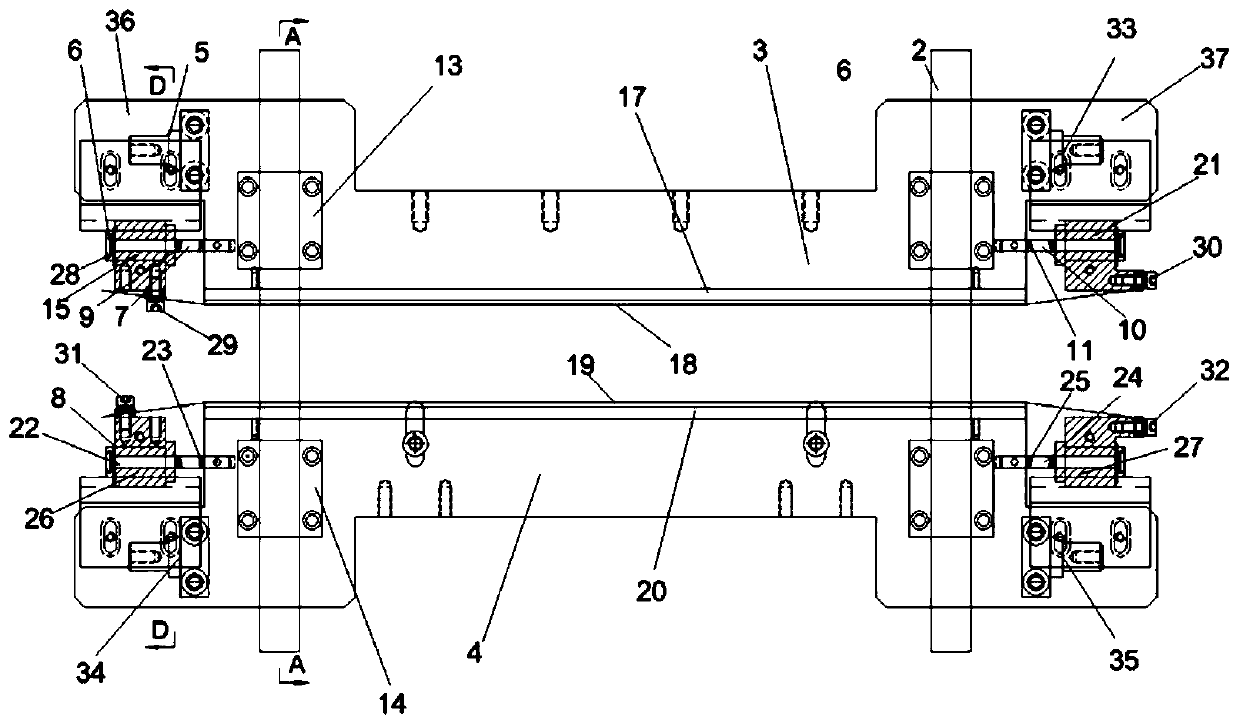

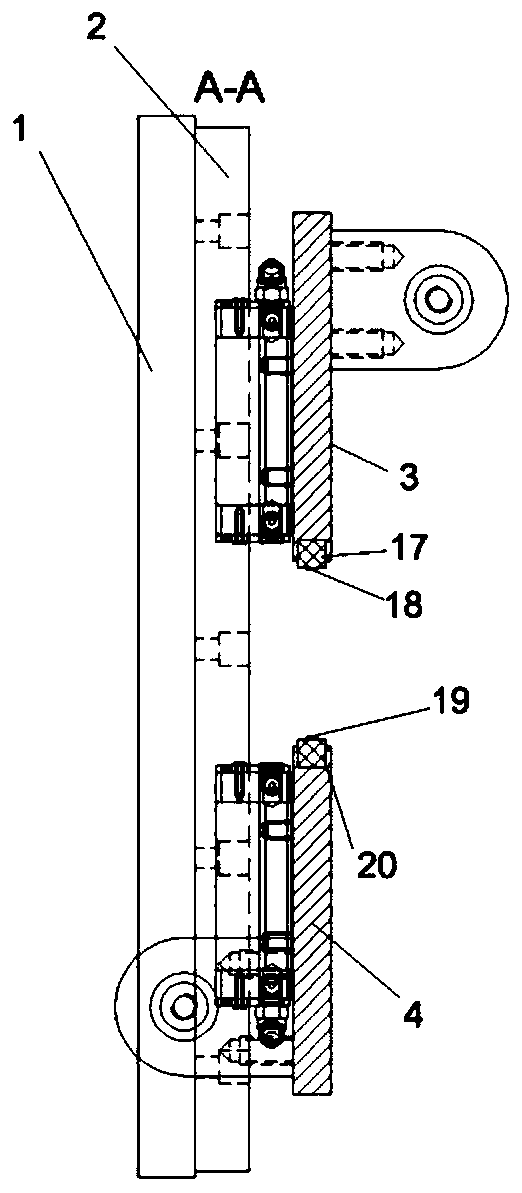

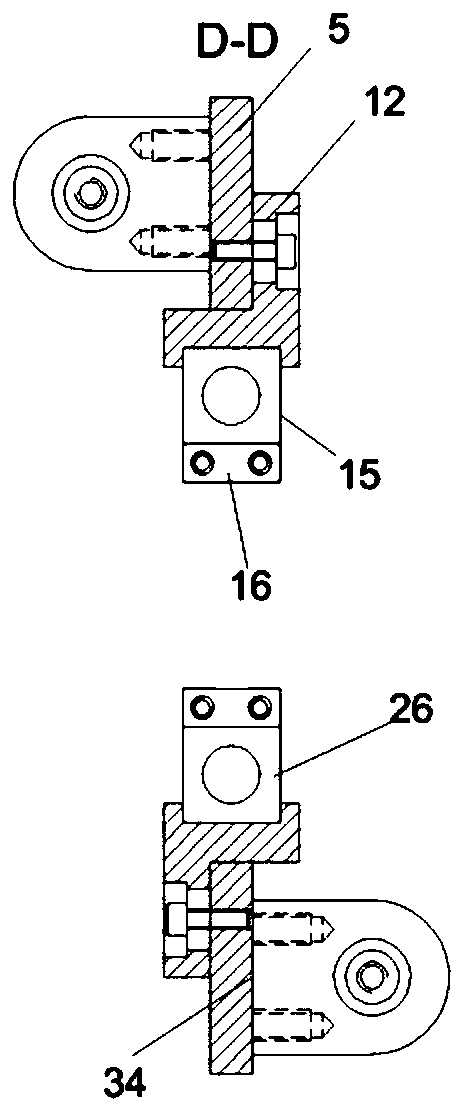

[0030] Such as Figure 1-4As shown, a heating and sealing device for a tundish machine dedicated to sanitary napkin products, including a support plate 1, two guide rails 2 installed on the support plate 1, an upper sealing plate 3 and a lower sealing plate 4 slidingly connected to the guide rails 2, And the upper heating wire 18 installed at the bottom of the upper sealing plate 3 and the lower heating wire 19 installed at the top of the lower sealing plate 4 . Both ends of the upper sealing plate 3 are provided with an upper heating wire tensioning structure matching the upper heating wire 18, and the two ends of the lower sealing plate 4 are provided with a lower heating wire tensioning structure matching the lower heating wire 19. The upper heating wire tensioning structure inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com