Construction method of self-priming municipal drainage system

A technology for a municipal drainage system and a construction method is applied in the construction field of a self-priming municipal drainage system, which can solve the problems of insufficient improvement efficiency, difficulty in predicting the development trend of urban construction, and high construction costs, and achieves the effect of great environmental protection significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

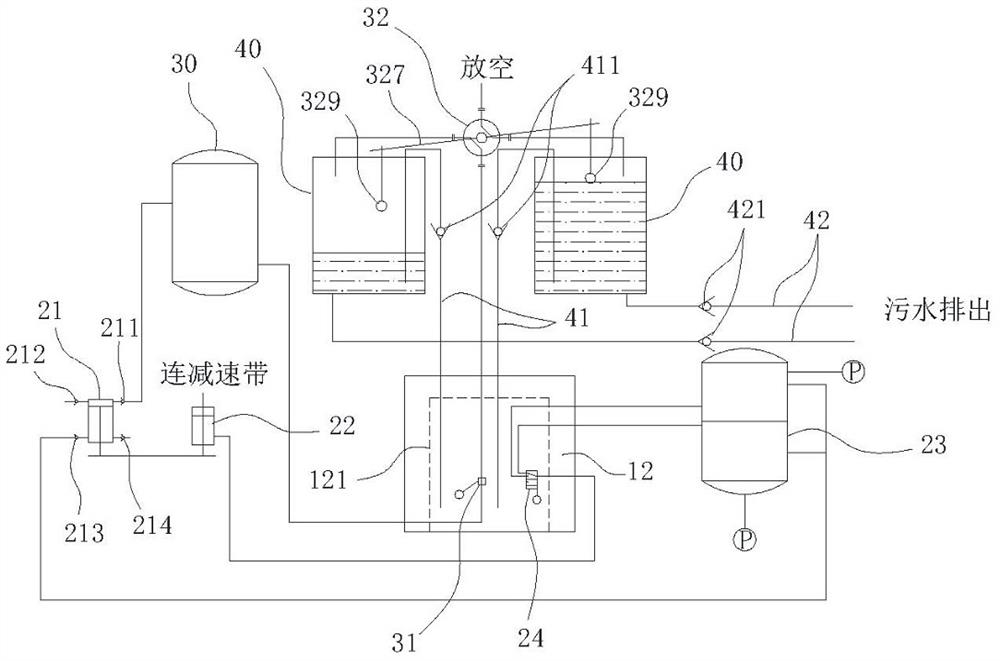

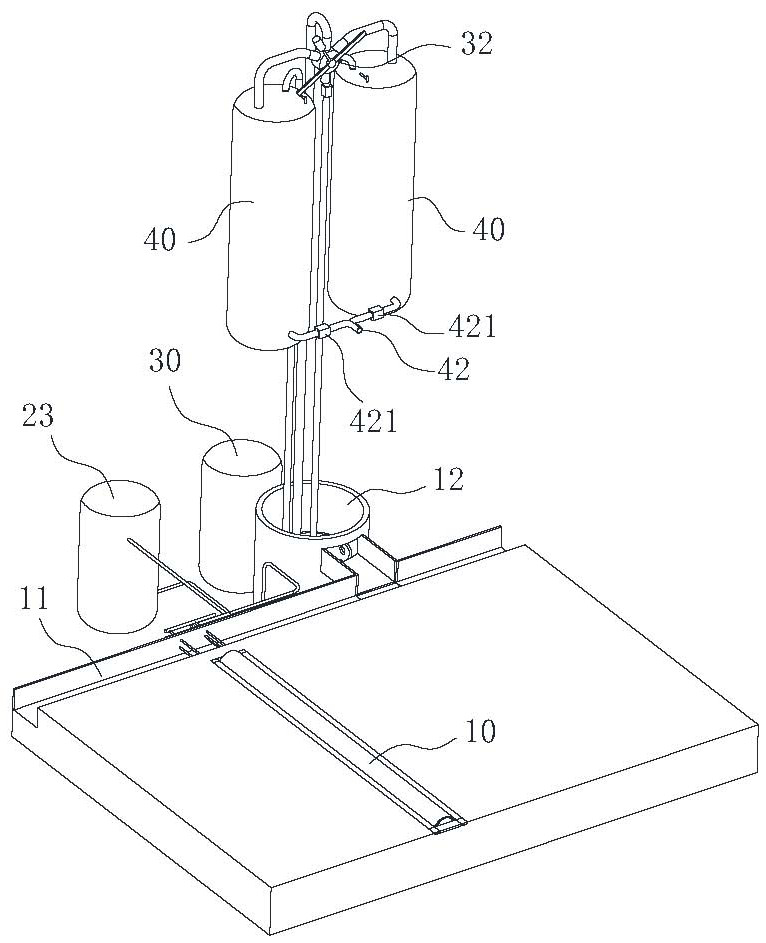

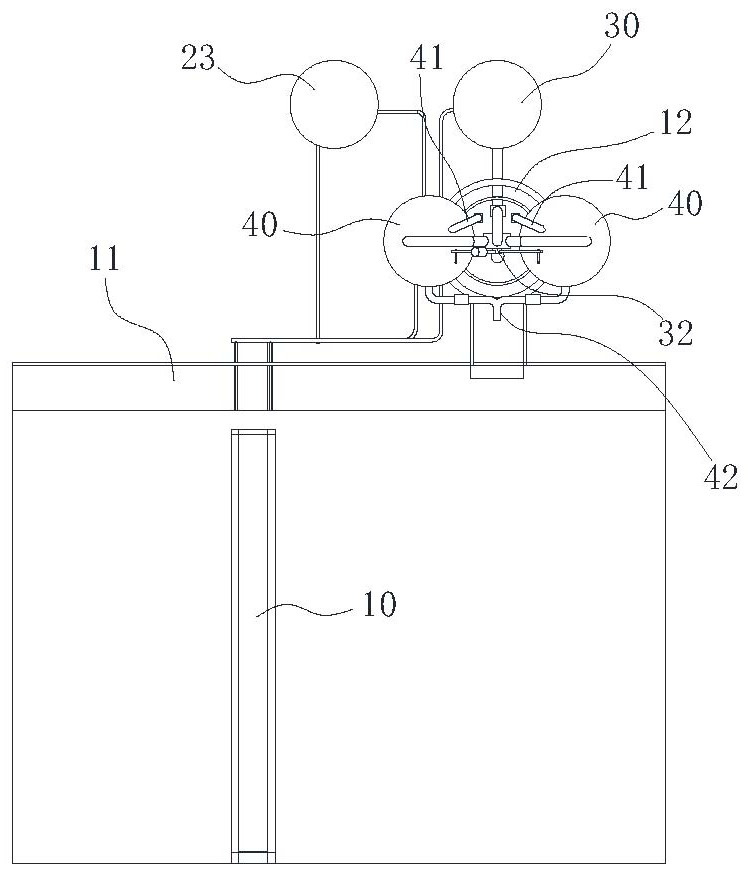

[0033] Such as figure 1 , 2 , 3, a low-lying road drainage system based on kinetic energy recovery, including a speed bump 10 arranged on the road surface, and a kinetic energy recovery device 20 arranged under the speed bump 10, the kinetic energy recovery device 20 is connected to the energy storage device, The energy storage device is connected with the suction device, one end of the suction device communicates with the drainage channel of the low-lying road surface, and the other end communicates with the urban drainage network. The present invention utilizes the kinetic energy recovery device 20 arranged under the deceleration belt 10 to recover the kinetic energy of the vehicle and temporarily stores it in the energy storage device. The accumulated water is pumped and drained into the urban drainage network. This invention does not need any external energy supply equipment. It is a simple and efficient road drainage solution. At the same time, the invention can recover ...

Embodiment 2

[0043] A construction method of a self-priming municipal drainage system, comprising the following steps:

[0044] S1: Excavate a strip-shaped foundation pit along the width direction of the road;

[0045] S2: installing the kinetic energy recovery device 20 in the foundation pit;

[0046] S3: Build installation positions for energy storage devices and suction devices on both sides of the road;

[0047] S4: install the energy storage device and the suction device, and connect the two, connect one end of the suction device to the inspection well 12 on both sides of the low-lying road, and connect the other end to the urban drainage network;

[0048] S5: connecting the kinetic energy recovery device 20 with the energy storage device;

[0049] S6: laying the deceleration belt 10 above the kinetic energy recovery device 20 .

[0050] In step S2, the kinetic energy recovery device 20 includes a vertically arranged first piston cylinder 21, and an elastic reset unit for driving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com