Mold supporting member, mold supporting structure and mold supporting method for irregular bevel pool wall of landscape pool

A landscape pool and irregular technology, which is applied to the preparation of building components on site, the connectors of formwork/formwork/work frame, and building construction, etc. It can solve the problems of easy pull-out, uneven height, and difficulty in surface form installation and other problems, to achieve the effect of reducing the difficulty of installation, good fastening performance, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The present invention will be further described in detail below in conjunction with the drawings.

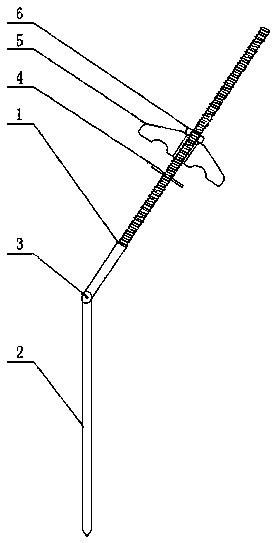

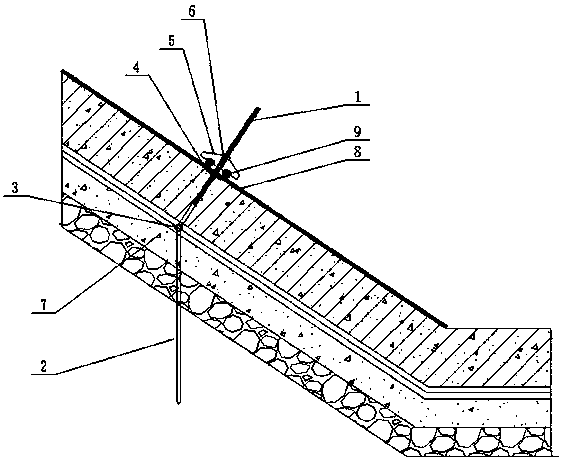

[0026] The reference signs in the drawings of the specification include: screw rod 1, plunger rod 2, hinge rod 3, formwork height positioning member 4, steel buckle 5, nut 6, concrete cushion 7, face mold 8, and threaded steel bar 9.

[0027] In this specific embodiment, a formwork member for the irregularly inclined pool wall of a landscape pool, such as figure 1 with figure 2 As shown, it includes a screw rod 1, an insert rod 2, a steel bar buckle 5, and a nut 6. The screw rod 1 and the insert rod 2 are located on the same vertical plane, and the upper end of the insert rod 2 and the lower end of the screw rod 1 are connected The hinged rod 3 is used for hinged connection, and the outer end of the hinged rod 3 is provided with a relatively rotating locking member on the hinged rod 3, so that the inserting rod 2 and the screw rod 1 are fixed and maintained at the required in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap