Chemical plant independent safety supervision system

A supervision system and technology for chemical plants, applied in the field of independent safety supervision systems in chemical plants, can solve problems such as lack of safety accidents in chemical plants, and achieve the effect of promoting the level of safety monitoring and low cost of transformation and upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

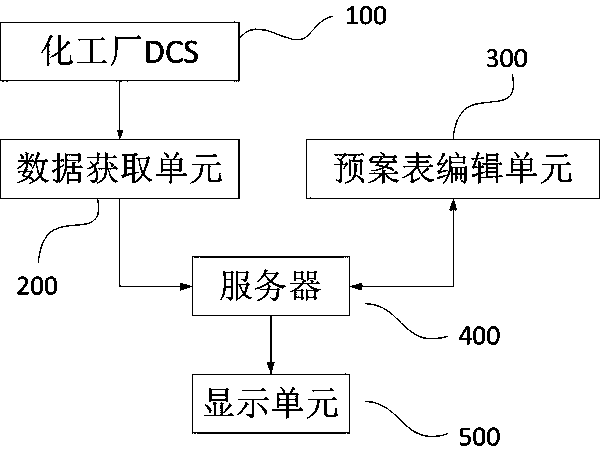

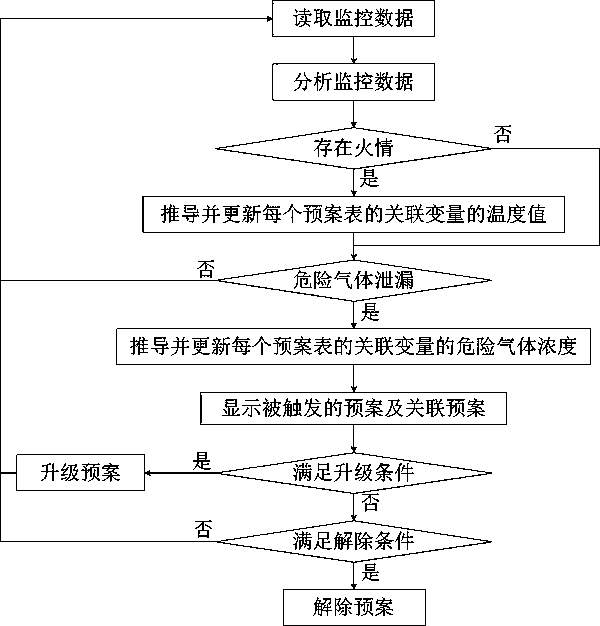

[0029] An independent safety supervision system for chemical plants, such as figure 1 As shown, the present embodiment includes a data acquisition unit 200, which is connected in communication with the DCS 100 of the chemical plant, and reads and stores all monitoring data of the chemical plant from the DCS of the chemical plant without affecting the process control work of the DCS 100 of the chemical plant. The optimal monitoring data is real-time data, followed by data with a small delay; the contingency table editing unit 300 is used to edit and store several contingency tables, and through interactive equipment, the contingency plans are electronically entered manually according to the accident handling rules of chemical plants In the pre-plan table editing unit 300, and can read and modify the pre-plan table, allowing the user to customize parameters or pre-plan according to needs; server 400 is used for real-time analysis of chemical plant monitoring data, to determine wh...

Embodiment 2

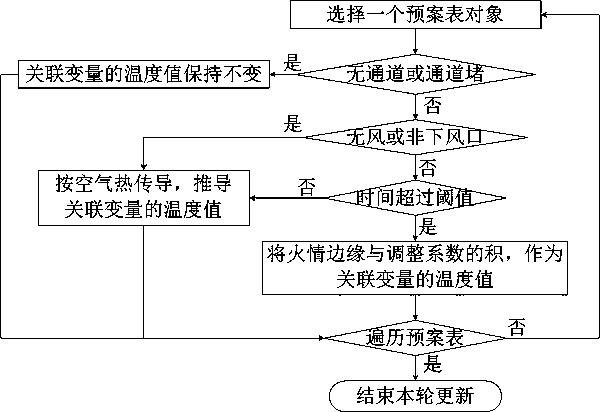

[0047] In this embodiment, a new improvement is made to the content of the plan table in the first embodiment, and at the same time, an update method of the plan table is improved. In this embodiment, the plan table also includes deduction time T and delay associated variables. When there is a security incident, the server 400 uses real-time monitoring data to deduce the level of the plan table after T time and the value of the associated variable, and the value of the associated variable after T time. value as the value of the deferred correlation variable. As shown in Table 1, in this embodiment, the deduction time T of the fire situation plan table of the gas storage tank 2 101 is 10 minutes. That is, after the gas storage tank 2 101 is on fire, the server 400 will deduce the values of the associated variables in the other contingency tables ten minutes later, so as to provide forward-looking reference data for accident disposal.

[0048] Compared with Embodiment 1, this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com