Split-type tbm cutter head joint characteristic scaling measurement method and system

A combined part and split-type technology, which is applied in tunnel engineering and underground engineering, can solve problems such as unexplained measurement methods for the coupling characteristics of the cutterhead joint surface, poor self-adaptation, complex devices, etc., and achieve reasonable simplification and strong versatility , Reliable and high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

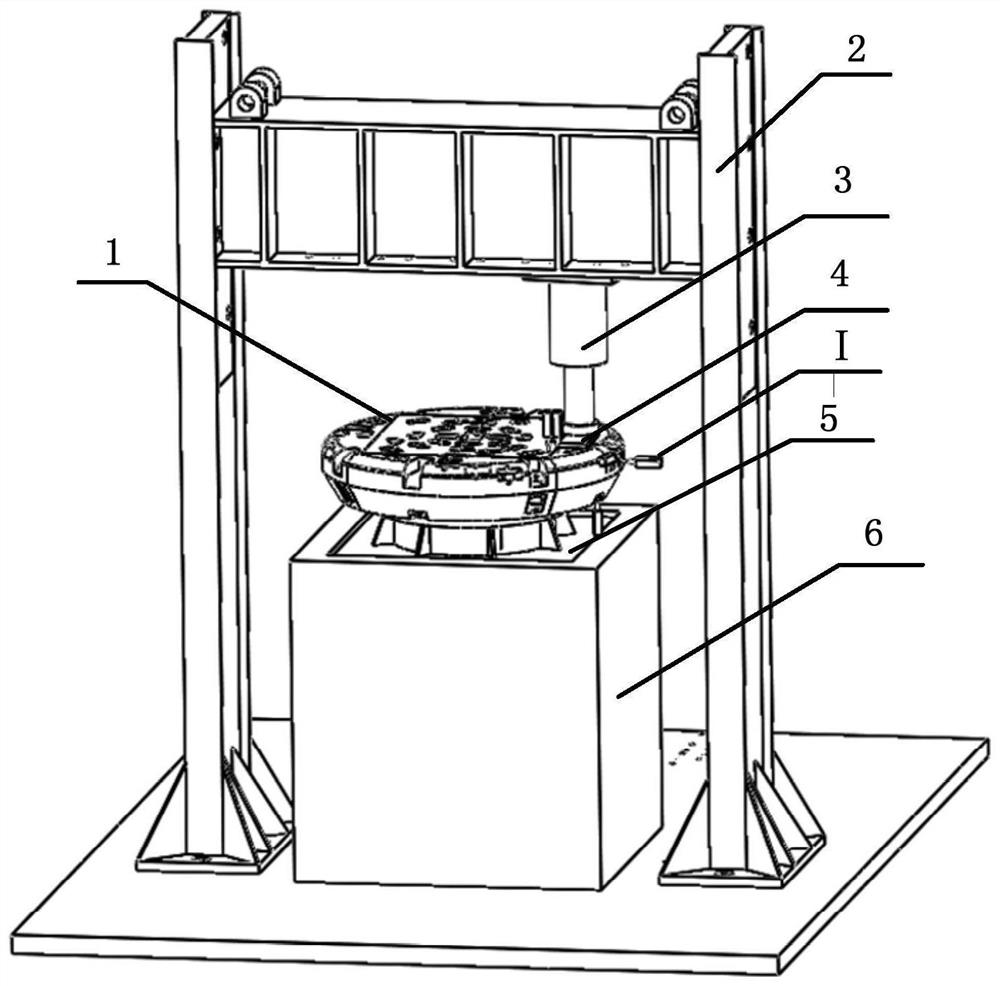

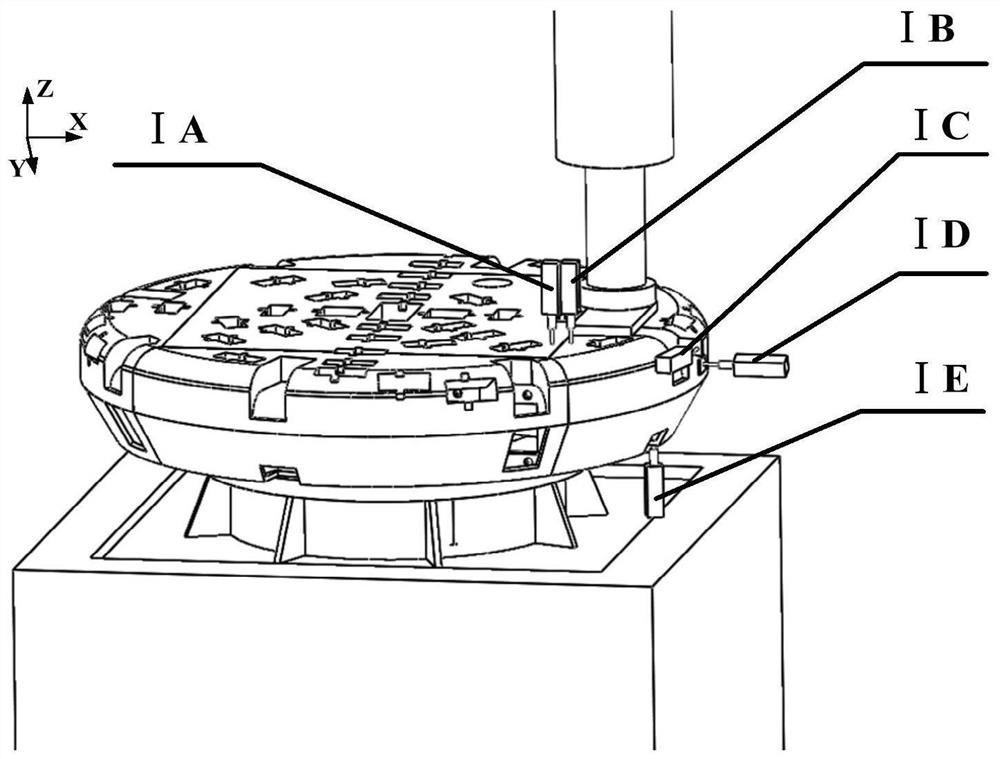

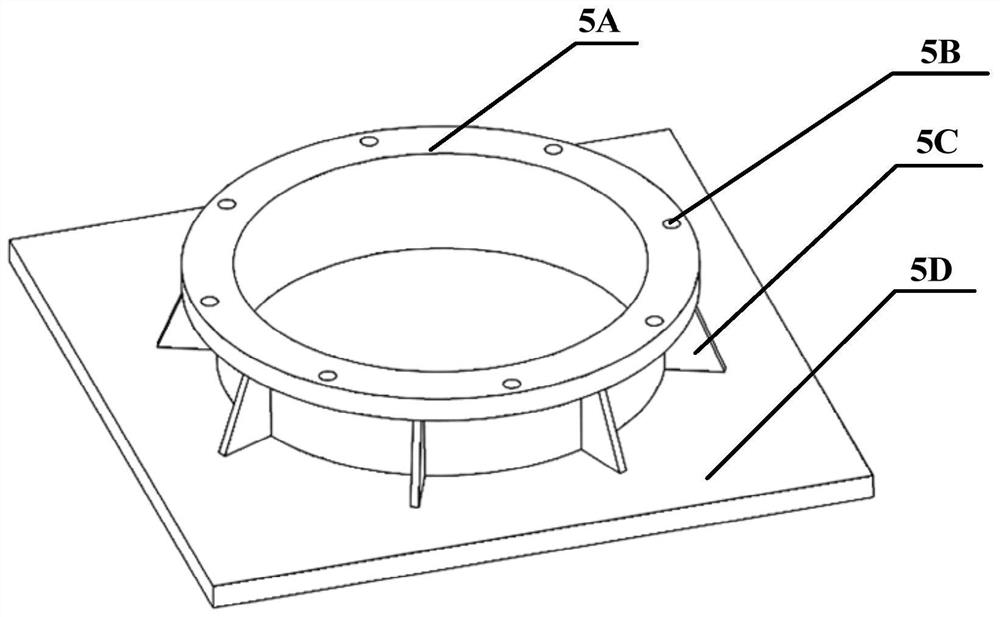

[0042] First, if figure 1 As shown, the joint characteristic measuring device of the embodiment of the present invention consists of a scale split TBM cutterhead 1, a gantry device 2, a digital jack 3, a loading backing plate 4, a displacement meter 1 for a distributed cutterhead, and a cutterhead fixture device 5 , a supporting pier column 6 and an acquisition system.

[0043] The equivalent scaled cutter head is to calculate the proportional relationship between the original size of the cutter head and the scaled scale through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com